Horizontal Flow Vertical Sludge Discharge Sedimentation Separation Device

一种沉淀分离、垂直排的技术,应用在沉降槽等方向,能够解决沉淀分离装置结构复杂、沉淀物易淤积在倾斜、堵塞排泥通道等问题,达到快速有效沉淀效果、解决斜板变形或坍塌、防止再悬浮的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

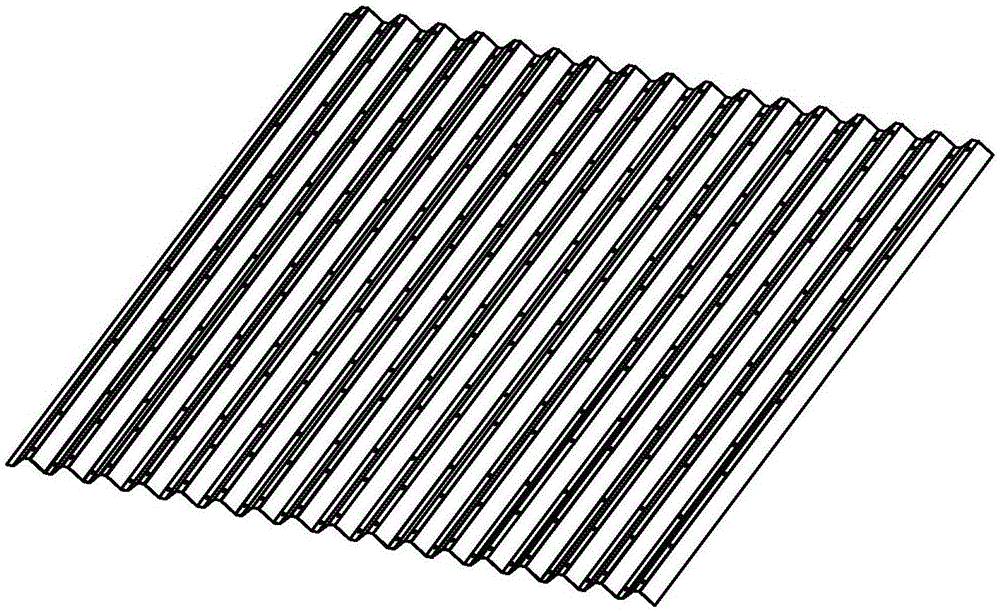

[0036] Such as Figure 1 to Figure 5 As shown, the horizontal flow vertical sludge discharge sedimentation separation device is installed in the sedimentation tank 12, which includes:

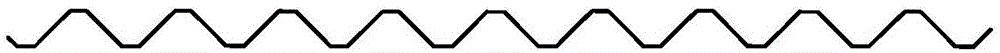

[0037] There are multiple corrugated plates 1, and these corrugated plates are arranged vertically relative to the horizontal plane, and the cross-section of the corrugated plates has a trapezoidal wave structure. The trapezoidal wave in this embodiment is an isosceles trapezoid, and the included angle α between the two waists and the corresponding valley bottom is 45°, and the width of the valley bottom is 1 cm. The width of the valley bottom can also select other sizes according to needs, usually Between 0.5 and 2 cm. The length of the two waists is 3 centimeters; the length of the waist can also be selected for other sizes as required, such as 2 to 3.5 centimeters.

[0038]In this embodiment, the surface of each corrugated pipe has a hydrophobic layer, thereby effectively reducing the resi...

Embodiment 2

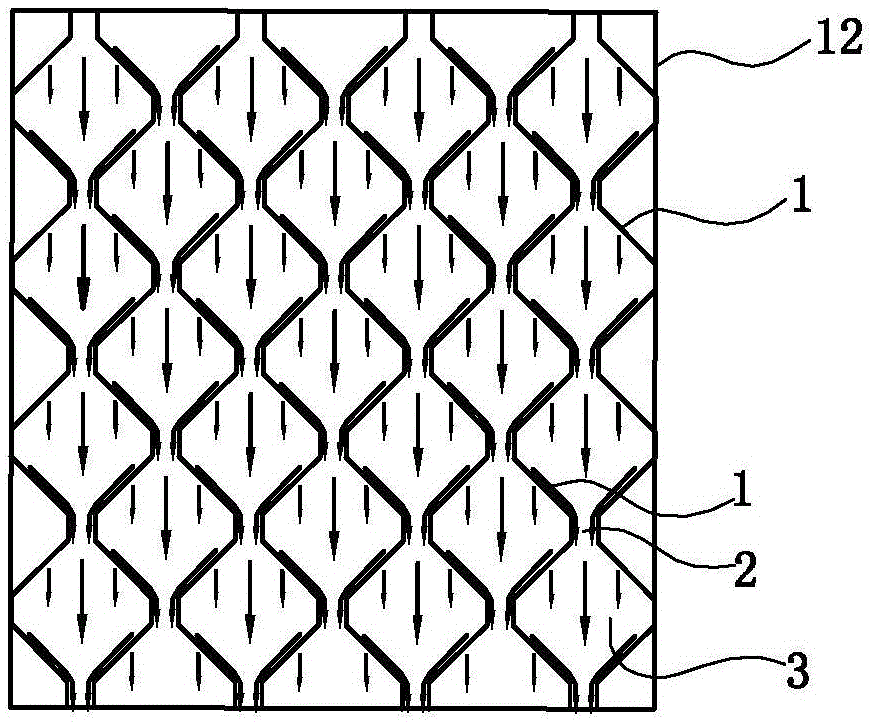

[0045] Such as Figure 6 to Figure 8 As shown, the horizontal flow vertical sludge discharge and sedimentation separation device includes:

[0046] There are multiple corrugated plates 1, and these corrugated plates are arranged vertically relative to the horizontal plane, and the cross-section of the corrugated plates has a trapezoidal wave structure. The trapezoidal wave in this embodiment is an isosceles trapezoid, and the included angle α between the two waists and the corresponding valley bottom is 45°, and the width of the valley bottom is 1 cm. The width of the valley bottom can also select other sizes according to needs, usually Between 0.5 and 2 cm. The length of the two waists is 3 centimeters; the length of the waist can also be selected for other sizes as required, such as 2 to 3.5 centimeters.

[0047] In this embodiment, the surface of each corrugated pipe has a hydrophobic layer, thereby effectively reducing the resistance of the surface of the corrugated plat...

Embodiment 3

[0053] as above Figure 9 to Figure 13 As shown, the waveform of the cross section of the corrugated plate 14 in this embodiment is a triangular wave, such as Figure 10 As shown, a plurality of clamping holes 15 are arranged at intervals at sharp corners of the corrugated plate. In this embodiment, the distance between adjacent locking holes is 9 cm.

[0054] In the gap between adjacent corrugated plates 14, a plurality of partitions 16 are arranged at intervals, and these partitions run longitudinally between adjacent corrugated plates; The space between them is suitable, and it is also a zigzag structure to facilitate the positioning of the partition and the corrugated board when they are assembled; the rest of the partition is a linear plate structure, and the width of this partition is larger than that of the adjacent partition. The minimum distance between the plates is smaller than the maximum distance between adjacent partitions, that is, part of the edge of the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com