Glue gun

A glue spray gun and nozzle technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problem of reduced adhesiveness, achieve the effect of increasing the contact area, ensuring viscosity, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

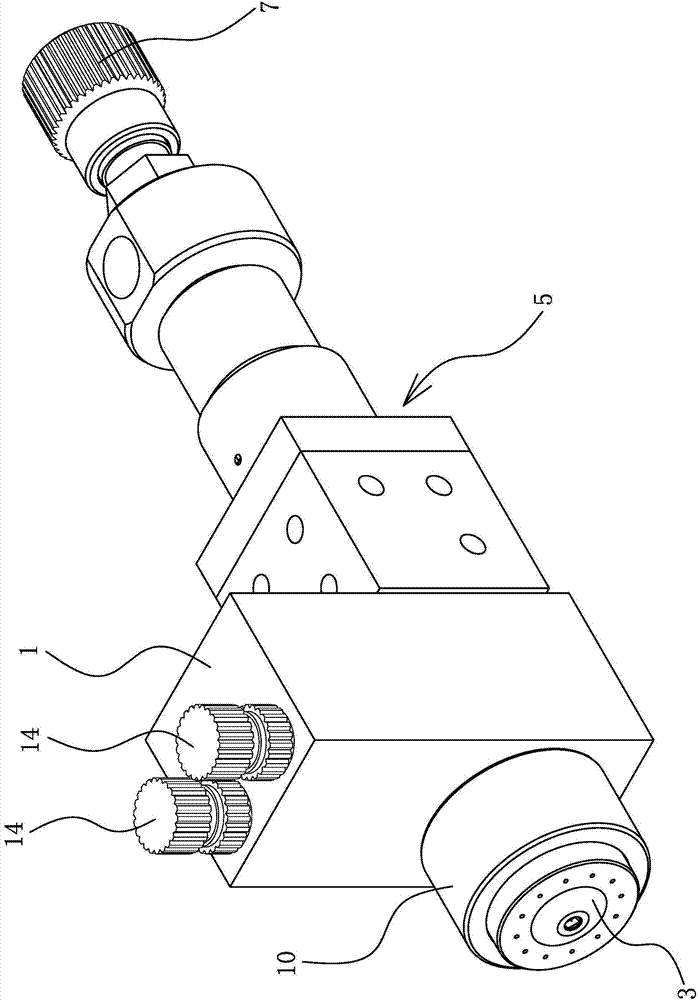

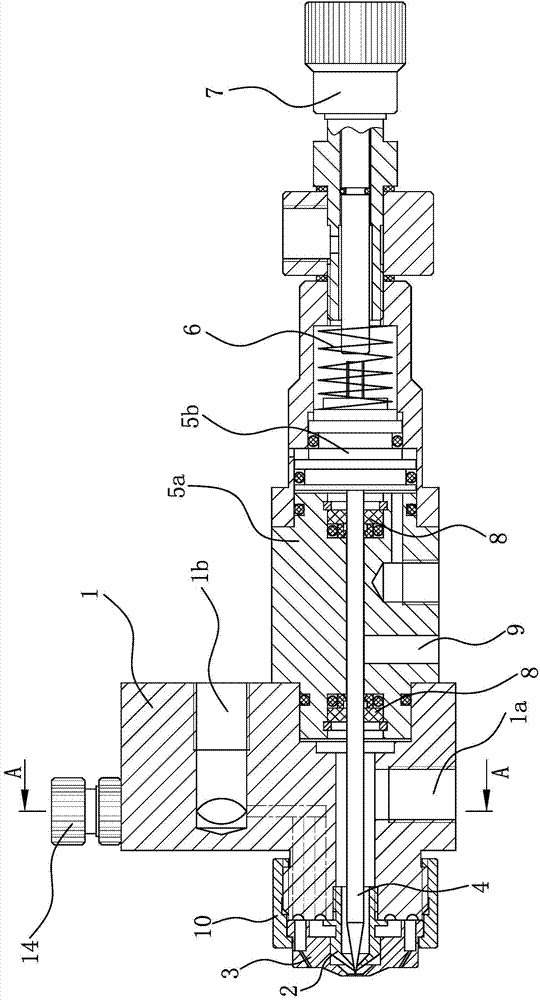

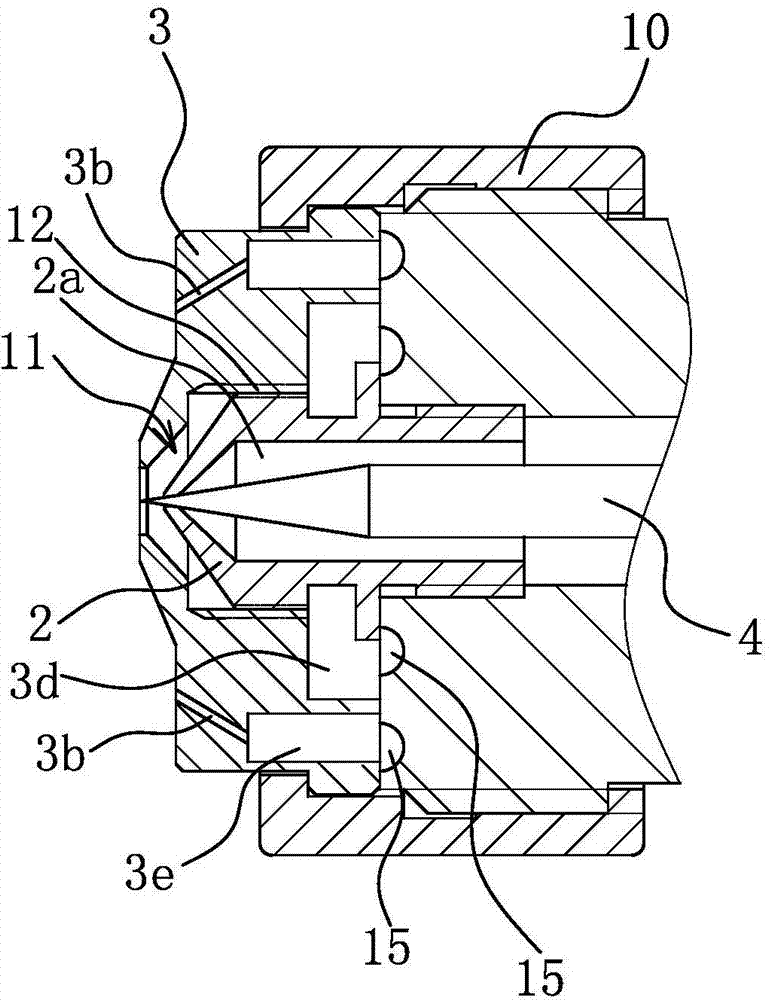

[0030] like figure 1 As shown, the glue gun includes a gun body 1 , a nozzle 2 , a wind cap 3 , a thimble 4 and a drive source 5 .

[0031] The gun body 1 has a glue feeding channel 1a and an air inlet channel 1b.

[0032] A glue outlet channel 2a is opened in the nozzle 2, and one port of the glue outlet channel 2a is a glue outlet 2b.

[0033] The nozzle 2 is fixed on the gun body 1 by threads, and the other port of the glue outlet channel 2a communicates with the glue inlet channel 1a.

[0034] The thimble 4 is pierced in the gun body 1, and the head of the thimble 4 is conical, which is a pointed structure. The thimble 4 passes through the glue outlet channel 2a and the head of the thimble 4 passes through the glue outlet 2b. The outer surface of the head of the thimble 4 can abut against the inner surface of the small glue outlet 2b and form a seal, and then block the small glue outlet 2b, that is, close the small glue outlet 2b. The axial movement of the thimble 4 le...

Embodiment 2

[0048] The structure and principle of this embodiment are basically the same as those of the first embodiment, except that the spiral passage 12 only includes several helical grooves on the inner surface of the wind cap 3 .

Embodiment 3

[0050] The structure and principle of this embodiment are basically the same as those of the first embodiment, except that the spiral channel 12 only includes several spiral grooves on the outer surface of the nozzle 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com