A special installation tool for automobile steel belt type elastic clamp

A technology for installing tools and elastic clamps, which is applied to manufacturing tools, hand-held tools, etc., can solve the problems of inability to meet the assembly requirements of different types of elastic clamps, clamp slippage, restrictions, etc., to achieve simple structure, meet assembly requirements, and operate Convenient and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

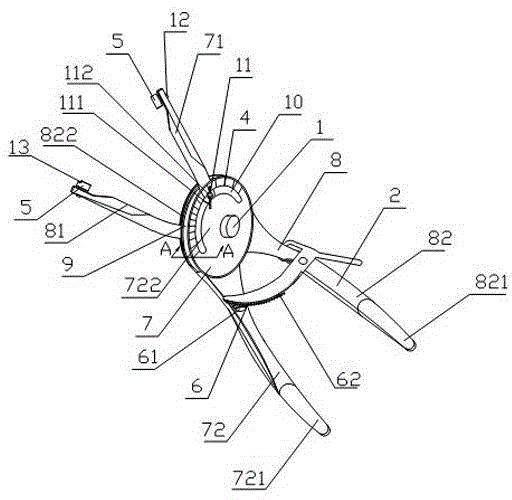

[0027] exist figure 1 In the shown embodiment, an automobile steel belt-type elastic clamp installation tool includes two clamp bodies 2 hinged to each other through a hinge shaft 1, and the clamp body 2 is provided with an adjustment chuck and an adjustment scale 4, and the adjustment chuck It can rotate circumferentially around the opening and closing direction of the two clamp bodies 2 , the clamp body 2 is provided with a hoop anti-slip device 5 , and a clamping locking mechanism 6 is provided between the two clamp bodies 2 .

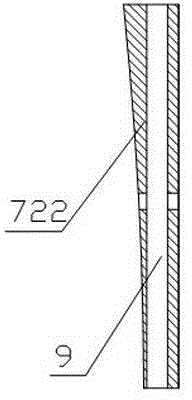

[0028] The clip body 2 includes a first clip body 7 and a second clip body 8 , and the adjusting clip is arranged on the first clip body 7 . The first clamping body 7 includes a first clamping head 71 and a first clamping handle 72, the first clamping head 71 is an adjusting chuck, and the first clamping handle 72 includes a first handle 721 and a first hinge integrally provided with the first handle 721 Disk 722, the first hinge disk 722 has a cir...

Embodiment 2

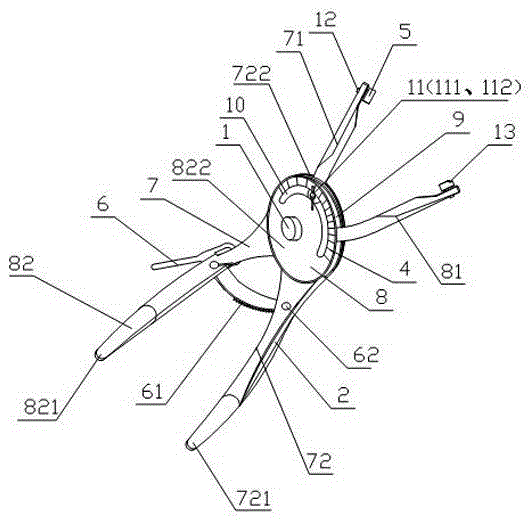

[0032] exist image 3 In the shown embodiment, an automobile steel belt-type elastic clamp installation tool includes two clamp bodies 2 hinged to each other through a hinge shaft 1, and the clamp body 2 is provided with an adjustment chuck and an adjustment scale 4, and the adjustment chuck It can rotate circumferentially around the opening and closing direction of the two clamp bodies 2 , the clamp body 2 is provided with a hoop anti-slip device 5 , and a clamping locking mechanism 6 is provided between the two clamp bodies 2 .

[0033] The clip body 2 includes a first clip body 7 and a second clip body 8 , and the adjusting clip is arranged on the second clip body 8 . The second clamping body 8 includes a second clamping head 81 and a second clamping handle 82, the second clamping head 81 is an adjusting chuck, and the second clamping handle 82 includes a second handle 821 and a second hinge integrally provided with the second handle 821 Disk 822, the second hinge disk 822...

Embodiment 3

[0037] exist Figure 4 In the shown embodiment, an automobile steel belt-type elastic clamp installation tool includes two clamp bodies 2 hinged to each other through a hinge shaft 1, and the clamp body 2 is provided with an adjustment chuck and an adjustment scale 4, and the adjustment chuck It can rotate circumferentially around the opening and closing direction of the two clamp bodies 2 , the clamp body 2 is provided with a hoop anti-slip device 5 , and a clamping locking mechanism 6 is provided between the two clamp bodies 2 .

[0038] The clip body 2 includes a first clip body 7 and a second clip body 8 , and adjusting clips are respectively arranged on the first clip body 7 and the second clip body 8 . The first clamping body 7 comprises a first clamping head 71 and a first clamping handle 72, the second clamping body 8 comprises a second clamping head 81 and a second clamping handle 82, and the first clamping head 71 and the second clamping head 81 are respectively adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com