Die for die-cutting machine

A die-cutting machine and mold technology, applied in the direction of perforating tools, manufacturing tools, metal processing, etc., can solve the problems of increased production costs, unspecified dimensions, waste of materials, etc., and achieve the goal of improving precision and quality, and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

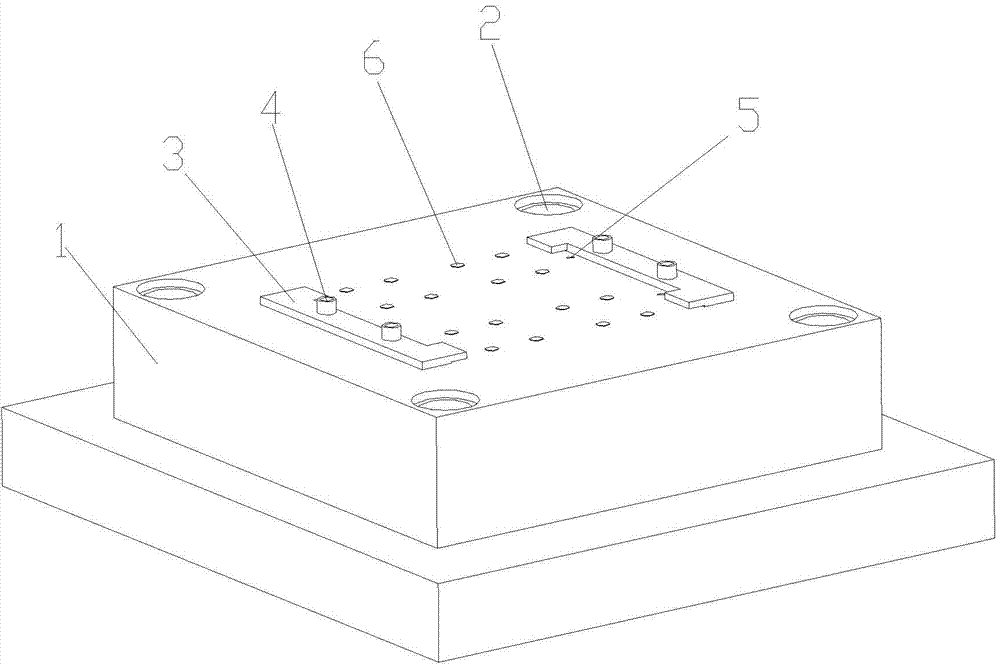

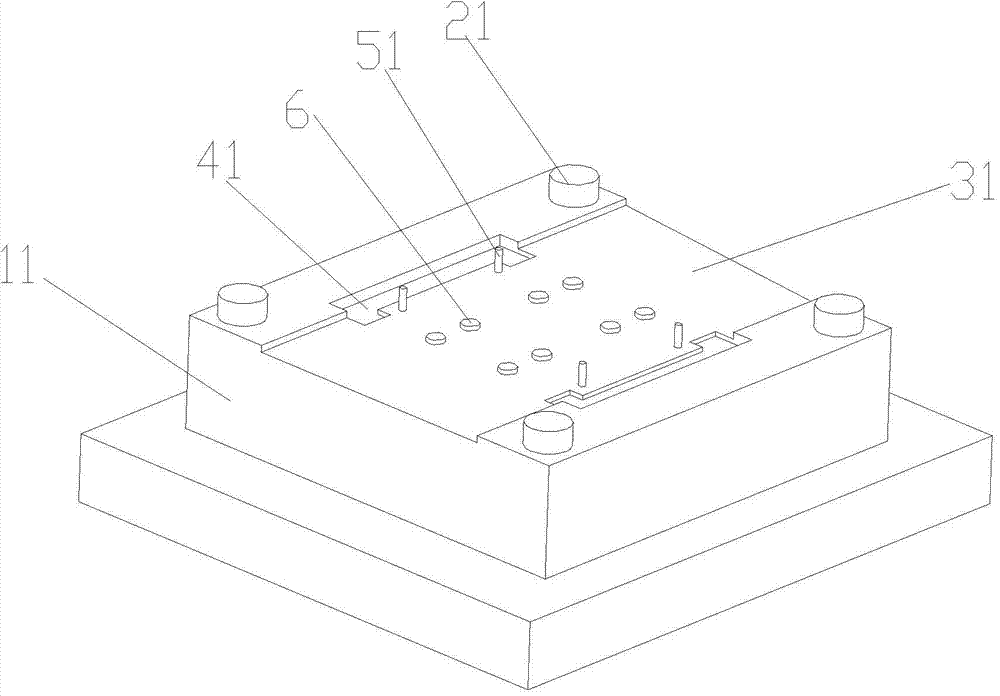

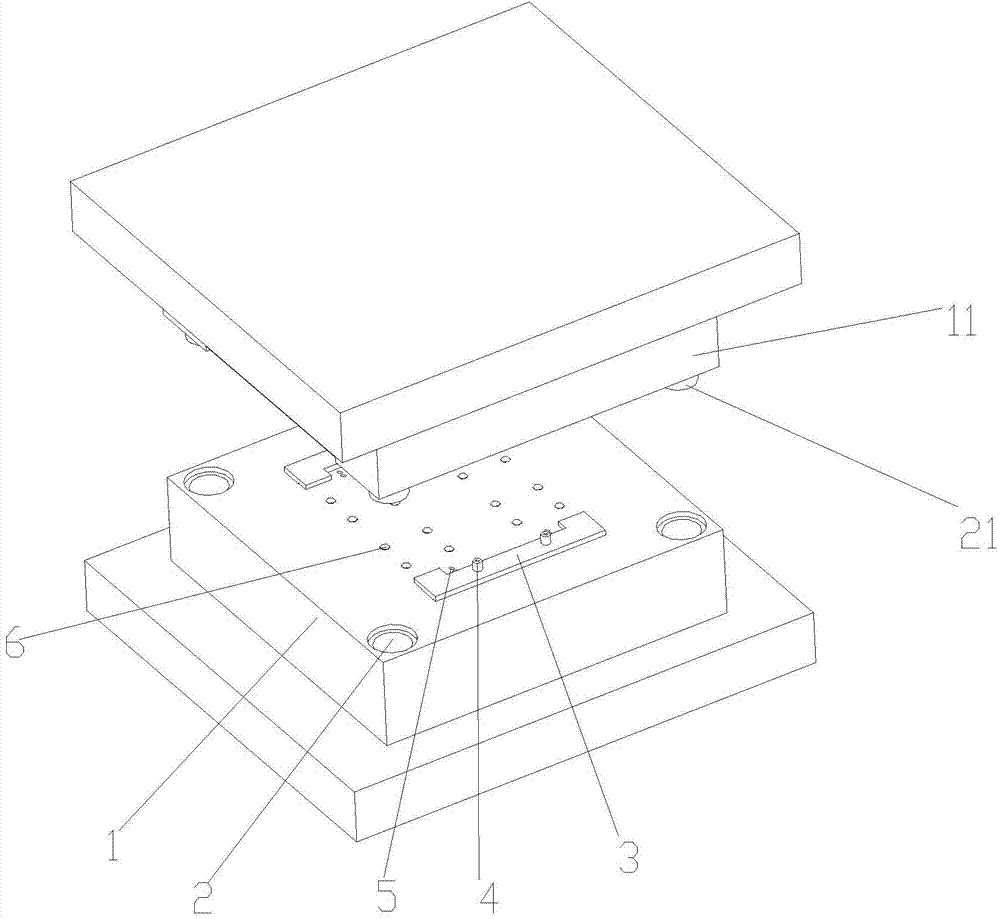

[0014] attached Figure 1-3 It is a mold for a die-cutting machine according to the present invention, including a male die and a female die, the male die includes a male template 1, and the four corners of the male template 1 are provided with positioning grooves 2; the male template 1 is provided with Two matched clamping plates 3; the clamping plates 3 are fixed by adjusting bolts 4; positioning holes 5 are provided on the opposite inner sides of the two clamping plates 3; There is a gap; the female mold includes a female template 11, and the four corners of the female template 11 are provided with positioning columns 21 that cooperate with the positioning groove 2 on the male template 1; the middle part of the female template 11 is a concave step 31; the lower Both sides of the concave step 31 are also provided with a clamp groove 41 matched with the clamp 3; the female template 11...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap