A flexible air extraction kit for composite material molding and its air extraction method

A composite material and kit technology, which is applied in the field of flexible air extraction kits for composite material molding and air extraction, can solve the problems of reducing production costs, bubble enrichment, and inability to solve bubble enrichment in special positions, so as to reduce production costs, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

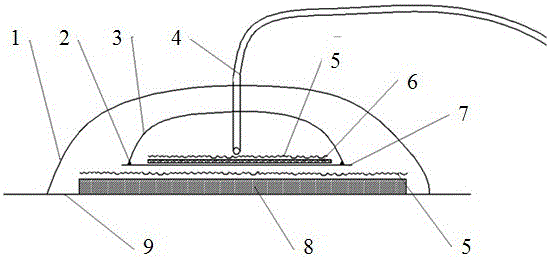

[0026] Embodiment 2, the difference from Embodiment 1 is that the air-tight outer wall 3 is a hard outer wall made of metal or hard plastic; the air-tight outer wall 3 is conical, conical, or tubular with a small top and a large bottom. The open cavity of better support exhaust pipe 4.

Embodiment 3

[0027] Embodiment 3, the difference from the above embodiment is that the air extraction pipe 4 adopts a soft tube to avoid damage to the VAP film 7 during the air extraction process, and the resin cannot enter the flexible air extraction kit for composite material molding. Therefore, In order to simplify the structure of the flexible suction kit for composite material molding, the air-conducting suction material 6 is removed, that is, the flexible suction kit for composite material molding is composed of VAP film 7, support material 5, soft suction pipe and air-tight outer wall 3 , simplifies the structural composition, reduces the production cost and improves the efficiency.

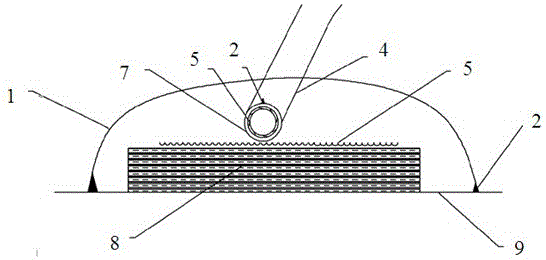

[0028] Embodiment three, such as figure 2 As shown, a method of using a flexible air extraction kit for composite material molding, a layer of support material 5 is laid on the surface of glass fiber cloth 8, the side of the air extraction kit VAP film 7 is placed flat on the support material 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com