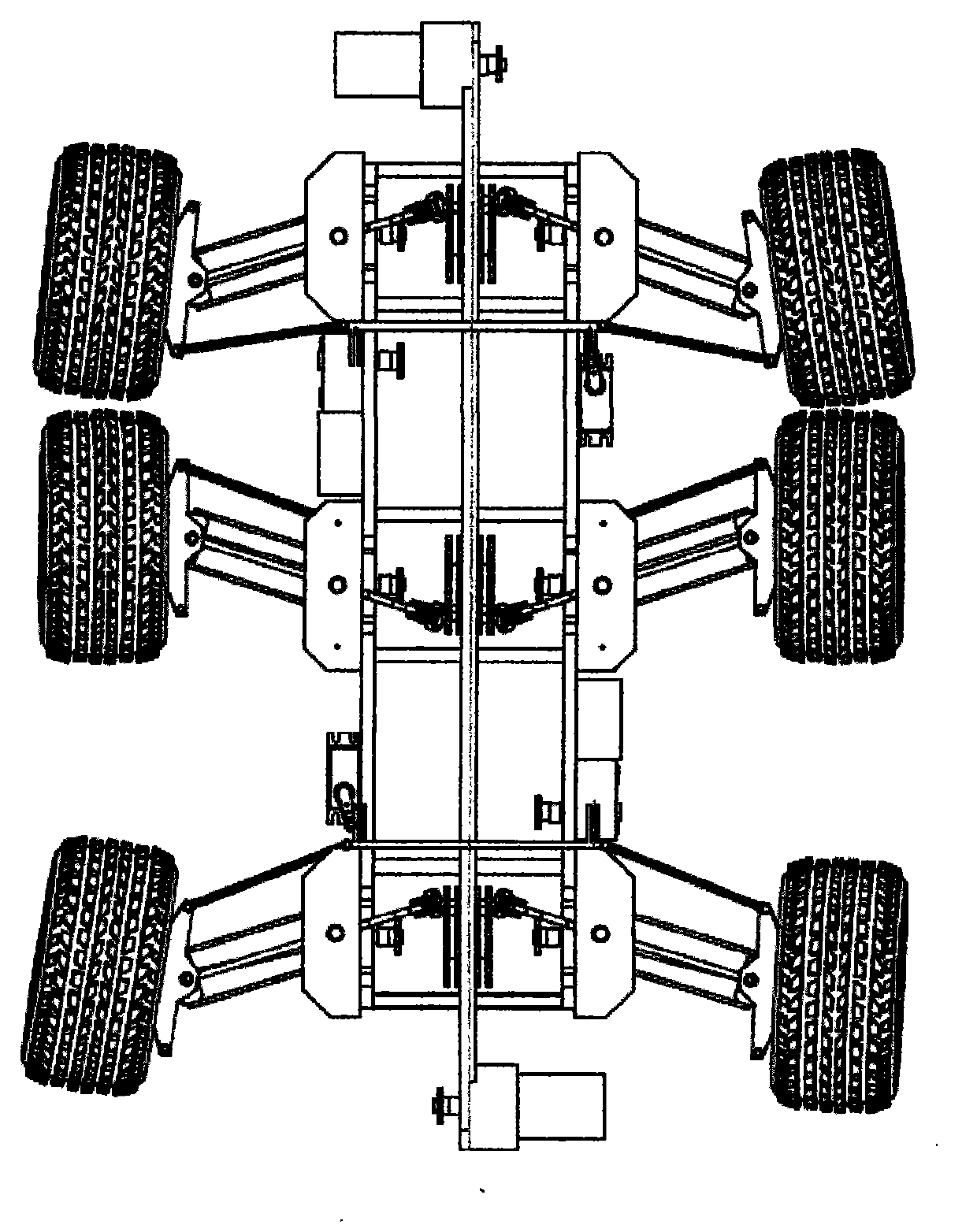

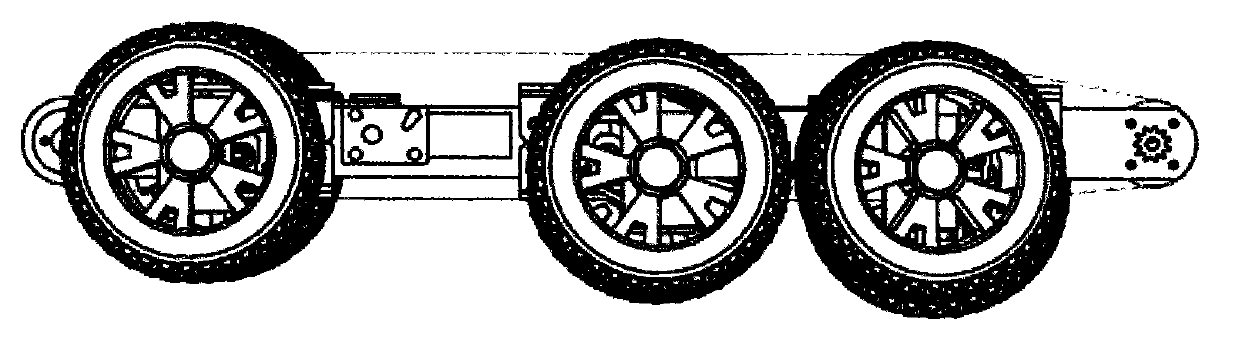

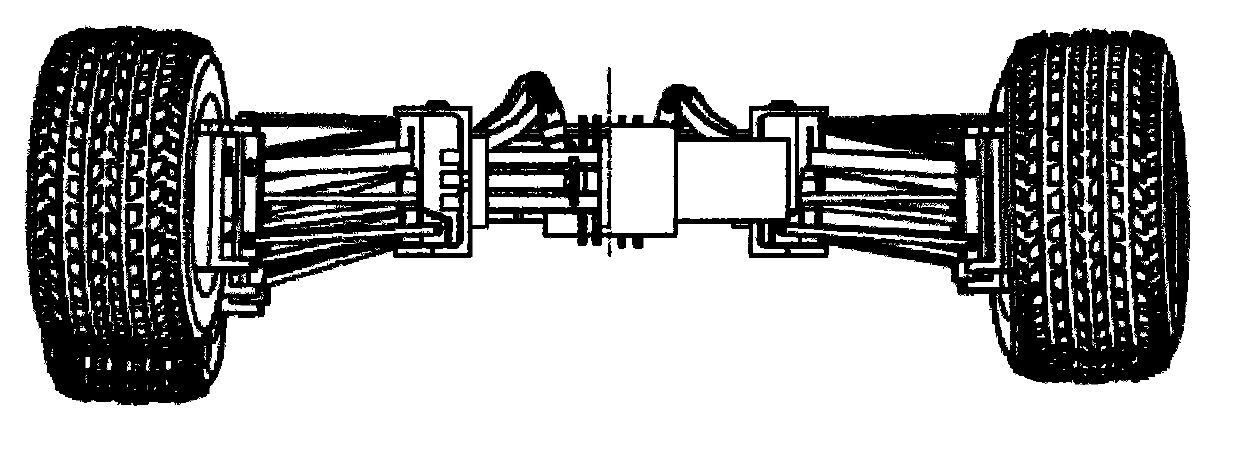

Wheel-legged robot chassis suspension device

A suspension device and robot technology, which is applied in the field of robot and vehicle chassis suspension, can solve the problems of robot chassis height, unstable center of gravity, and poor adaptability of crawler robots, etc., and achieve improved obstacle surmounting performance, benefit from stealth, and improve space utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Realization of legged walking function:

[0036] The leg type walking mechanism is made up of leg type mobile driven sprocket 18, joint bearing 27, rocking arm 2, steering seat 21, lower rocker arm 11, wheel end steering seat 5, wheel end steering seat 8, joint bearing 27 and driven Sprocket 18 is eccentrically hinged, and one end of joint bearing is hinged with upper rocker arm 2, and the middle part of upper rocker arm 2 is connected with steering seat 21 by a through shaft, and the rocking arm end and two rocking bars are connected with wheel end steering seat 8. The leg-type walking drive motor 13 drives the leg-type mobile driven wheel 18 through the driving sprocket 14, and then relies on the rotation of the driven sprocket 18 to make the upper rocker arm 2 produce a spatial cycle motion, and then drives the entire suspension device to complete an approximate circular motion; at the same time Relying on the set phase relationship among the six suspension devices, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com