Support structure for linear segmental transportation of ships

A technology of sectional transportation and support structure, applied in the directions of transportation and packaging, slipway, dry dock, etc., can solve the problems of difficult operation, serious, sectional paint damage, etc., to reduce welding damage, simple operation, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

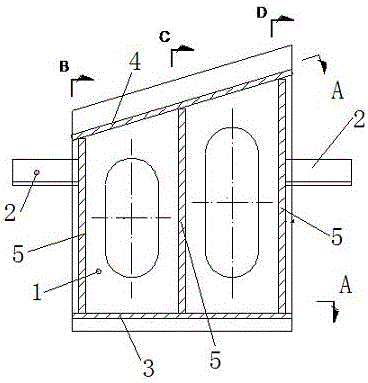

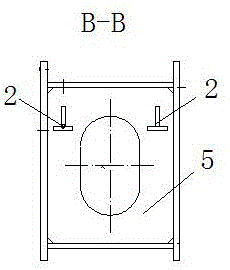

[0016] Such as Figure 1-Figure 5 As shown, the ship’s linear segmented transportation support structure includes a main vertical plate 1, a bottom plate 3, a cover plate 4 and a reinforced partition 5, the main vertical plate 1 is respectively fixed on the front and rear ends of the reinforced partition 5, and the cover plate 4 and the bottom plate 3 are respectively fixed on the upper and lower ends of the reinforced partition 5, the main vertical plate 1, the bottom plate 3, the cover plate 4 and the reinforced partition 5 form an overall frame structure, the reinforced partition 5 is generally at least three, and the main vertical Forklift supports 2 are installed side by side on the reinforced partitions 5 on both sides of the plate 1. The forklift supports are mainly used to support and fix the lifting support structure. The main vertical plate 1, bottom plate 3, cover plate 4 and reinforcement There are lightening holes on the dividing plate 5, such as Figure 6 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com