A disc type yarn tension device

A yarn tension, disc type technology, applied in the field of winders, can solve problems such as yarn breakage, and achieve the effect of avoiding yarn breakage and hand injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

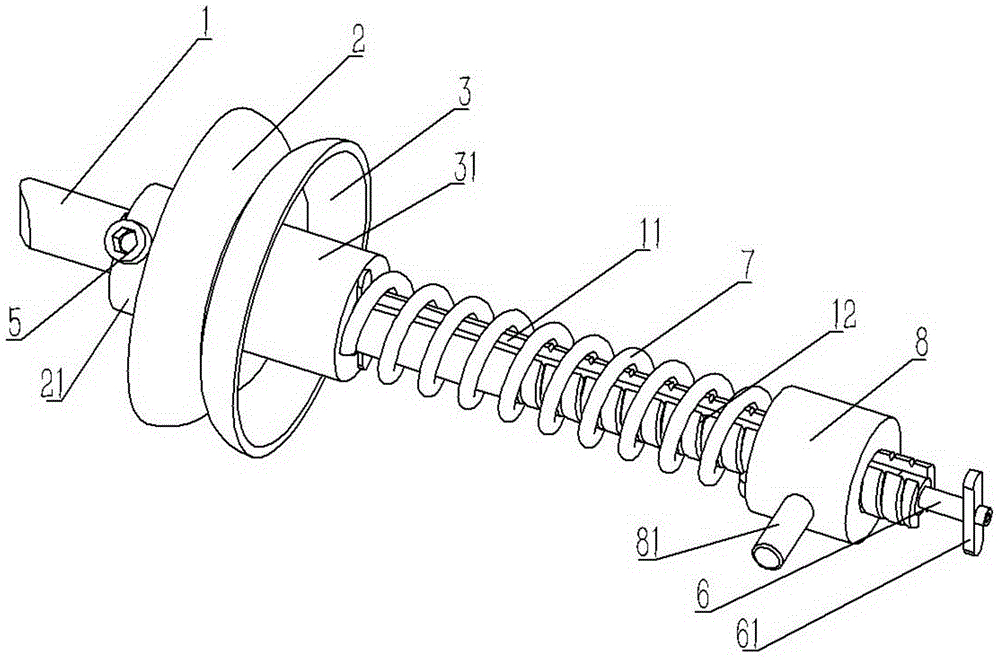

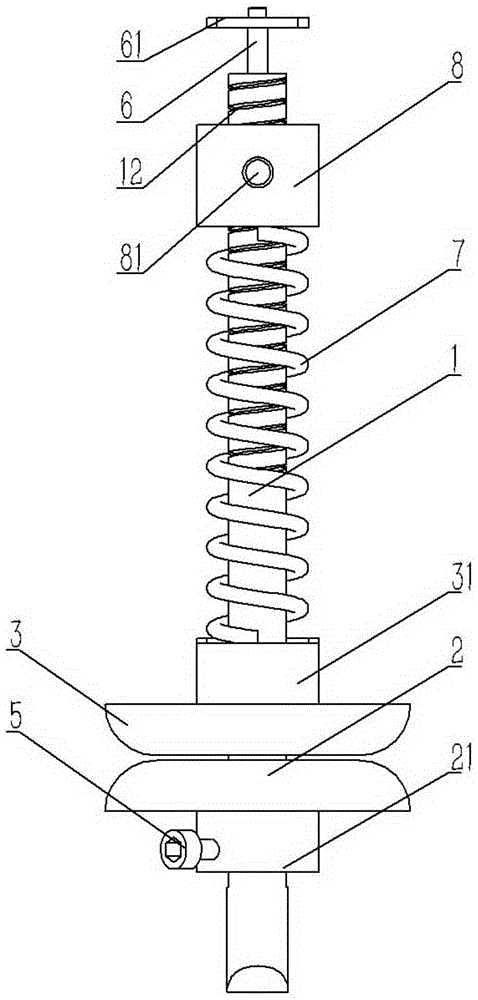

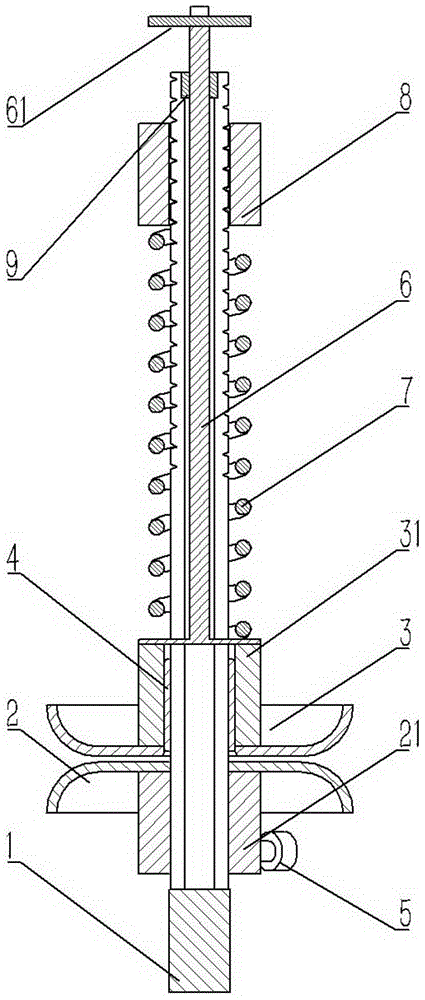

[0020] Example: see figure 1 , 2 , Shown in 3, a kind of disk-type yarn tensioning device comprises shaft rod 1, and shaft rod 1 is inserted with fixed disc 2 and movable disc 3, fixed disc 2 and movable disc 3 are respectively fixed with The first shaft sleeve 21 and the second shaft sleeve 31, the first shaft sleeve 21 of the fixed disc 2 is fixed on the shaft rod 1 by the set screw 5, and the second shaft sleeve 31 of the movable disc 3 is pressed against There is a compression spring 7, and the other end of the compression spring 7 is pressed against the adjustment sleeve 8, and the adjustment sleeve 8 is screwed on the shaft 1, and the front end surface of the shaft 1 is formed with cutting shaft 1 side walls Waist-shaped slot 11, the waist-shaped slot 11 of the shaft rod 1 is inserted with a T-shaped pull bar 6, and the head of the pull bar 6 is fixed on the second bushing 31 of the movable disc 3 and is located between the compression spring 7 and the first Between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com