Elevator multi-fold door operator device

A door operator and elevator technology, applied in the field of elevator components, can solve the problems of complex structure, danger and high cost, and achieve the effects of simple and compact structure, preventing door panels from falling off, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

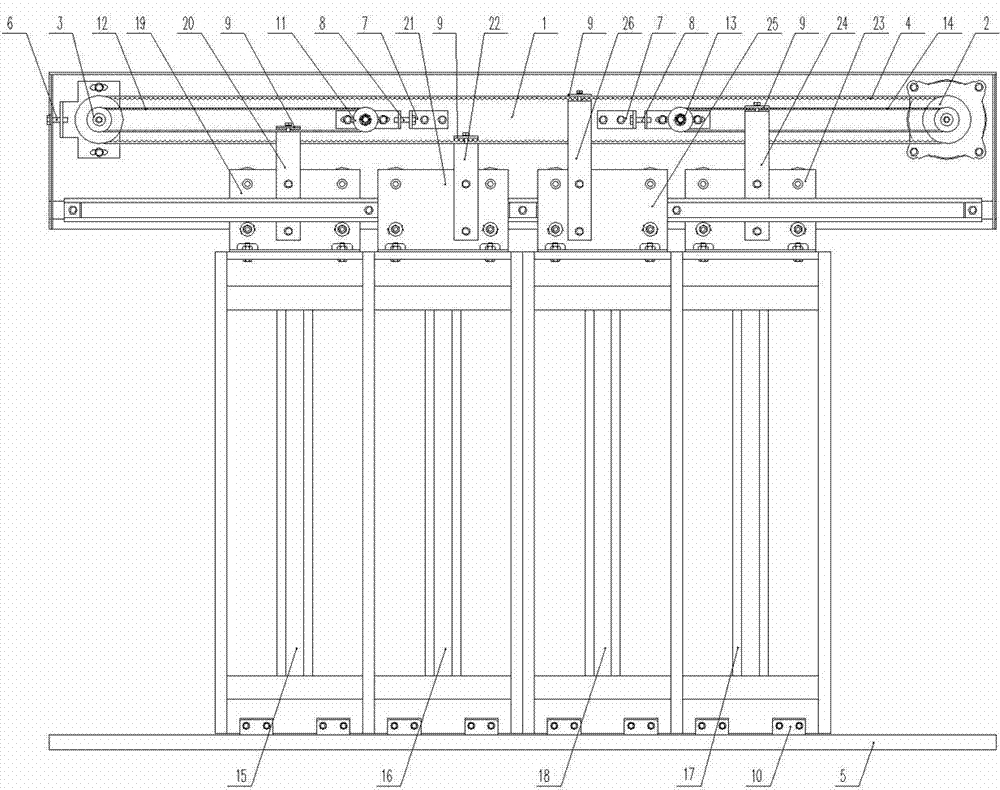

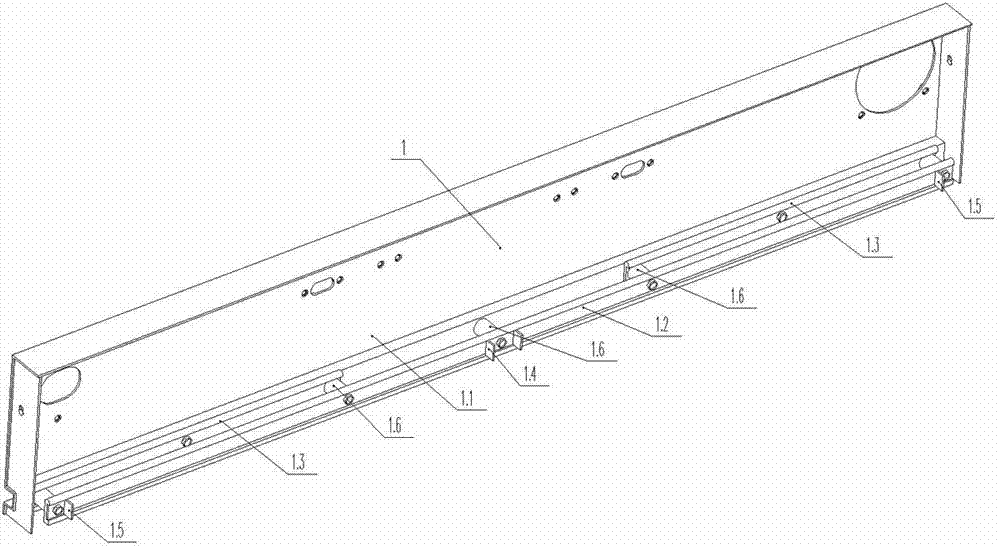

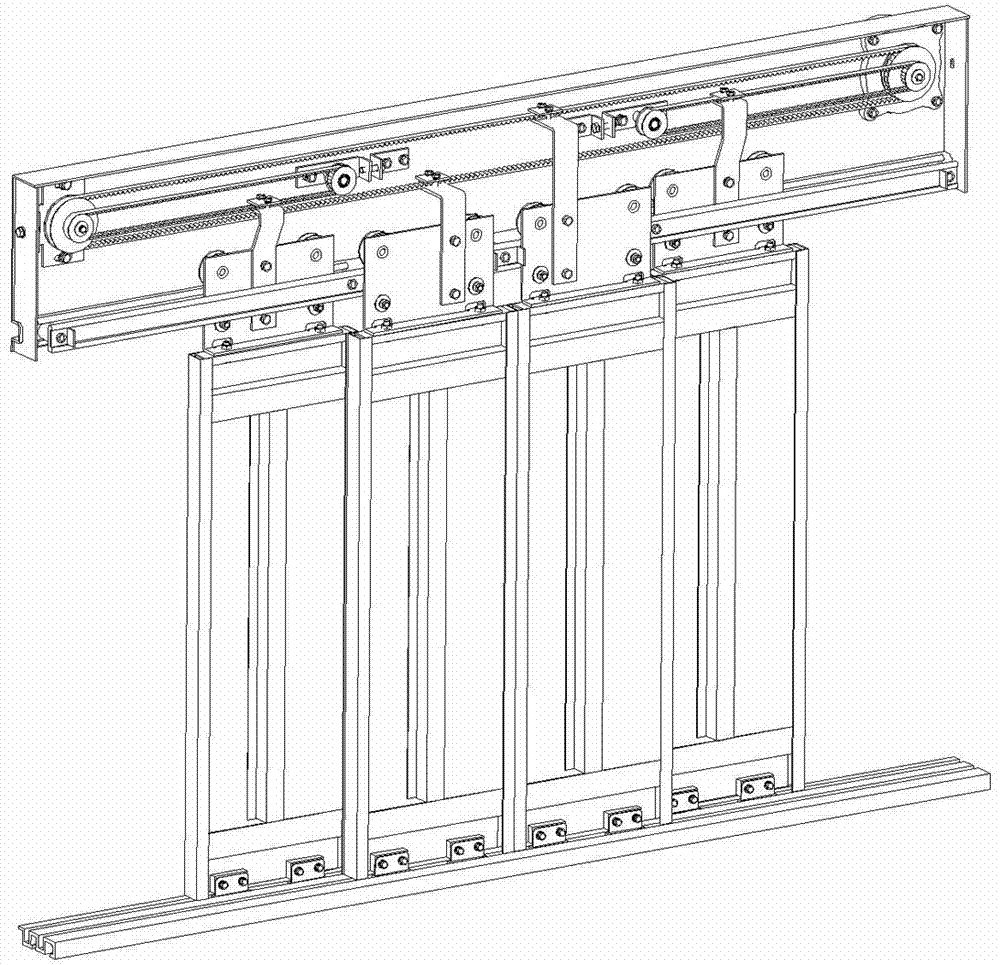

[0041] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the double-folding door machine device in this embodiment includes a door machine bottom plate assembly 1, a drive motor 2, a main pulley assembly 3, a main timing belt 4, two sets of left and right small pulley assemblies and a small timing belt (left Small pulley assembly 11, left small synchronous belt 12, right small pulley assembly 13, right small synchronous belt 14), two door panels on the left and right sides (left slow door panel 15, left shutter panel 16, right slow door panel 17 , right shutter plate 18), left slow door hanging plate assembly 19, left shutter hanging plate assembly 21, right shutter hanging plate assembly 23, right slow door hanging plate assembly 25, left slow door hanging arm 20, left shutter hanging arm 22, Right shutter boom 24, right slow door boom 26, door machine sill 5.

[0042] The door machine base plate assembly 1 includes a door machine base plate 1.1, a long guide rai...

Embodiment 2

[0050] like Figure 5 As shown, the unilateral double-folding door machine device in this embodiment includes a door machine bottom plate assembly 1, a drive motor 2, a main pulley assembly 3, a main timing belt 4, a small main pulley assembly 31, a small timing belt 32, and a slow door plate 33 , shutter plate 34, slow door hanger assembly 35, slow door arm 36, shutter hanger assembly 37, shutter arm 38, door machine sill 5.

[0051] The door machine base plate assembly 1 includes a door machine base plate 1.1, a long guide rail, a short guide rail, a baffle plate for fully opening the door, a baffle plate for fully closing the door, and a sleeve. The straight line where the short guide rail is located is parallel to the long guide rail on the same horizontal plane. The door machine bottom plate assembly 1 is used for supporting the whole door machine and installing other parts of the door machine. The door machine sill 5 is stationary relative to the door machine floor asse...

Embodiment 3

[0059] like Figure 6As shown, the three-fold door machine device in this embodiment includes a door machine bottom plate assembly 1, a drive motor 2, a main pulley assembly 3, a main timing belt 4, four groups of left and right small pulley assemblies and a small timing belt (left Small pulley assembly 41, left small timing belt 42, left middle pulley assembly 43, left middle timing belt 44, right small pulley assembly 45, right small timing belt 46, right middle pulley assembly 47, right middle timing belt 48 ), three door panels on the left and right sides (left slow door panel 49, left middle door panel 50, left shutter panel 51, right slow door panel 54, right middle door panel 53, right shutter panel 52), door machine sill 5.

[0060] The door machine base plate assembly 1 includes a door machine base plate 1.1, a long guide rail, two short guide rails on the left and right, and two middle guide rails on the left and right. The two short guide rails are located on the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com