Biogas digester

A biogas digester and biogas technology, applied in the field of biogas digesters, can solve the problems of biogas leakage, many failures, and high maintenance requirements, and achieve the effects of high gas production rate, good sealing performance, and strengthening of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

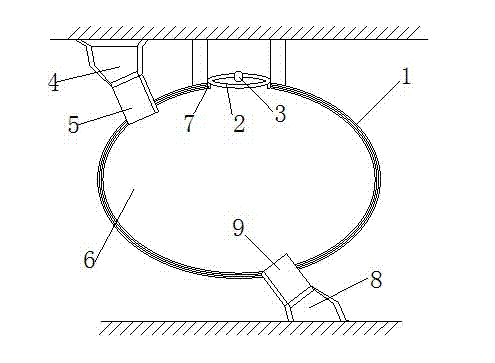

[0016] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0017] Such as figure 1 As shown, a biogas digester includes a biogas digester body, the biogas digester body is in the shape of an ellipsoid, and the internal hollow structure of the biogas digester body forms a fermentation room; the top of the biogas digester body is provided with a movable cover matching its shape and size , the movable cover is provided with an air duct; the movable cover includes a biogas cover and a water sealing device, and the water sealing device is in sealing contact with the mouth of the biogas digester; the feeding port and the discharging port are sequentially arranged along the material flow direction, so that The feed port...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap