System and method for stimulating and predicting melt thermocapillary convection process

A convection process and prediction system technology, applied in self-area melting methods, chemical instruments and methods, crystal growth, etc., can solve the problem of not considering the deformation of the free surface of the liquid bridge in the melting zone, affecting the accuracy of research results, and failing to meet the microgravity level Requirements and other issues to achieve the effect of reducing blindness and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

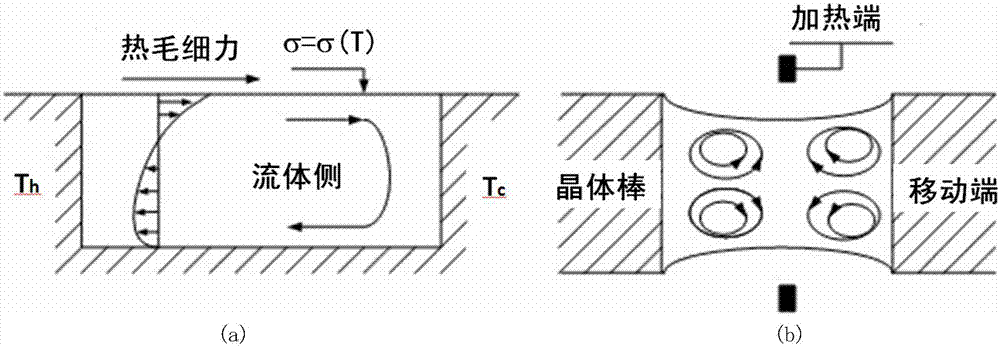

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

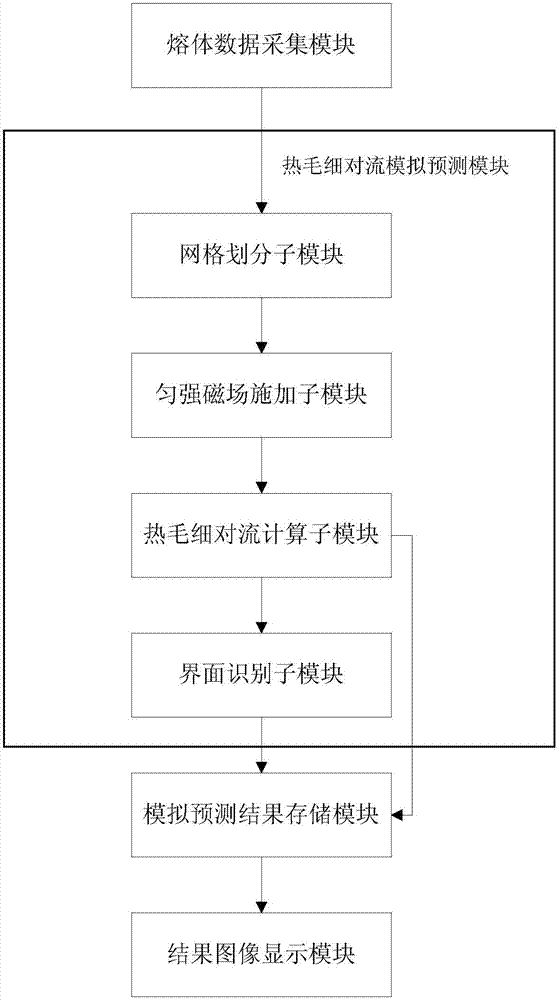

[0055] Such as image 3 As shown, the melt thermocapillary convection process simulation prediction system of this embodiment includes:

[0056] Melt data acquisition module: used to collect the geometric parameters of the melt liquid bridge area, the physical property parameters of the medium, the physical property parameters of the melt environment and the initial state parameters of the melt thermocapillary convection process, and transmit them to the thermocapillary convection simulation prediction module ;

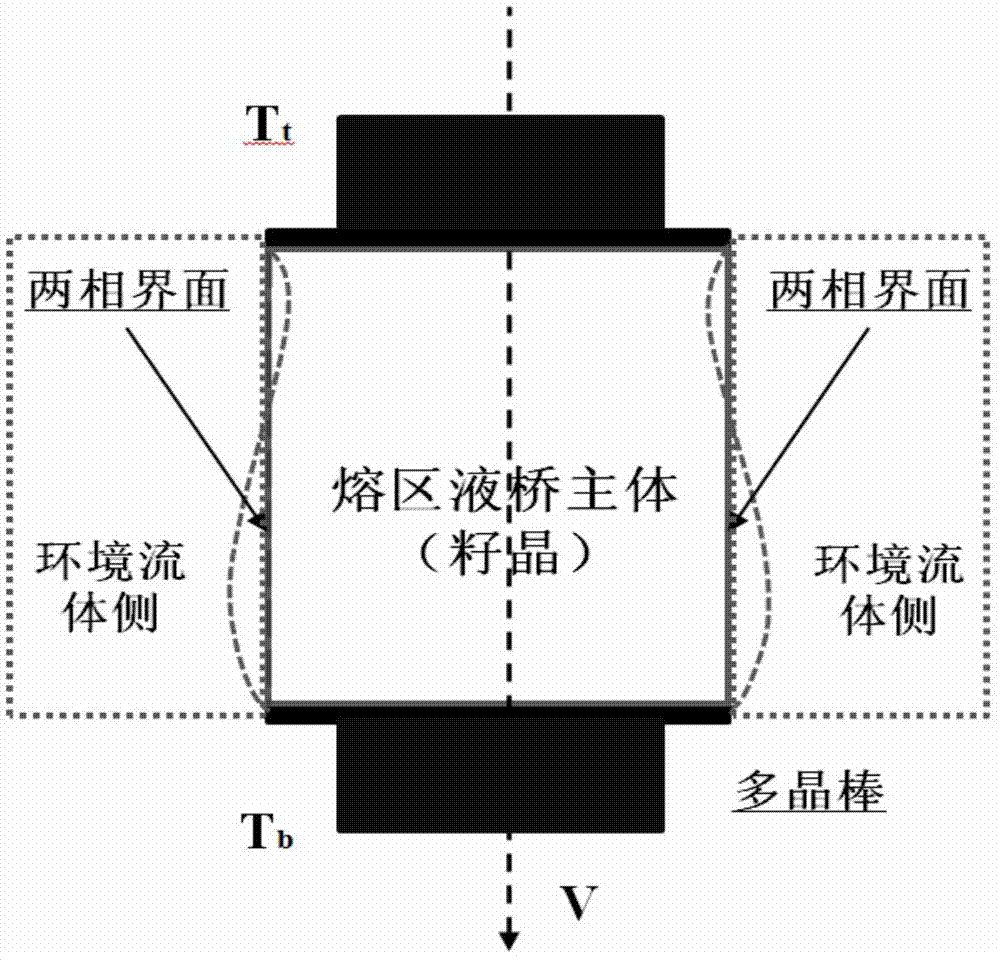

[0057] The geometric parameters of the melt liquid bridge area include: liquid bridge diameter, liquid bridge height, environmental measurement width, and environmental measurement height;

[0058] The physical parameters of the medium in the melt bridge area include: the density of the melting zone medium, the dynami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com