X-type micro-hole spinneret plate

A spinneret and microporous technology, applied in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problems of poor product quality, retention, moisture absorption, perspiration, etc., and achieve breathability Good, good moisture absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

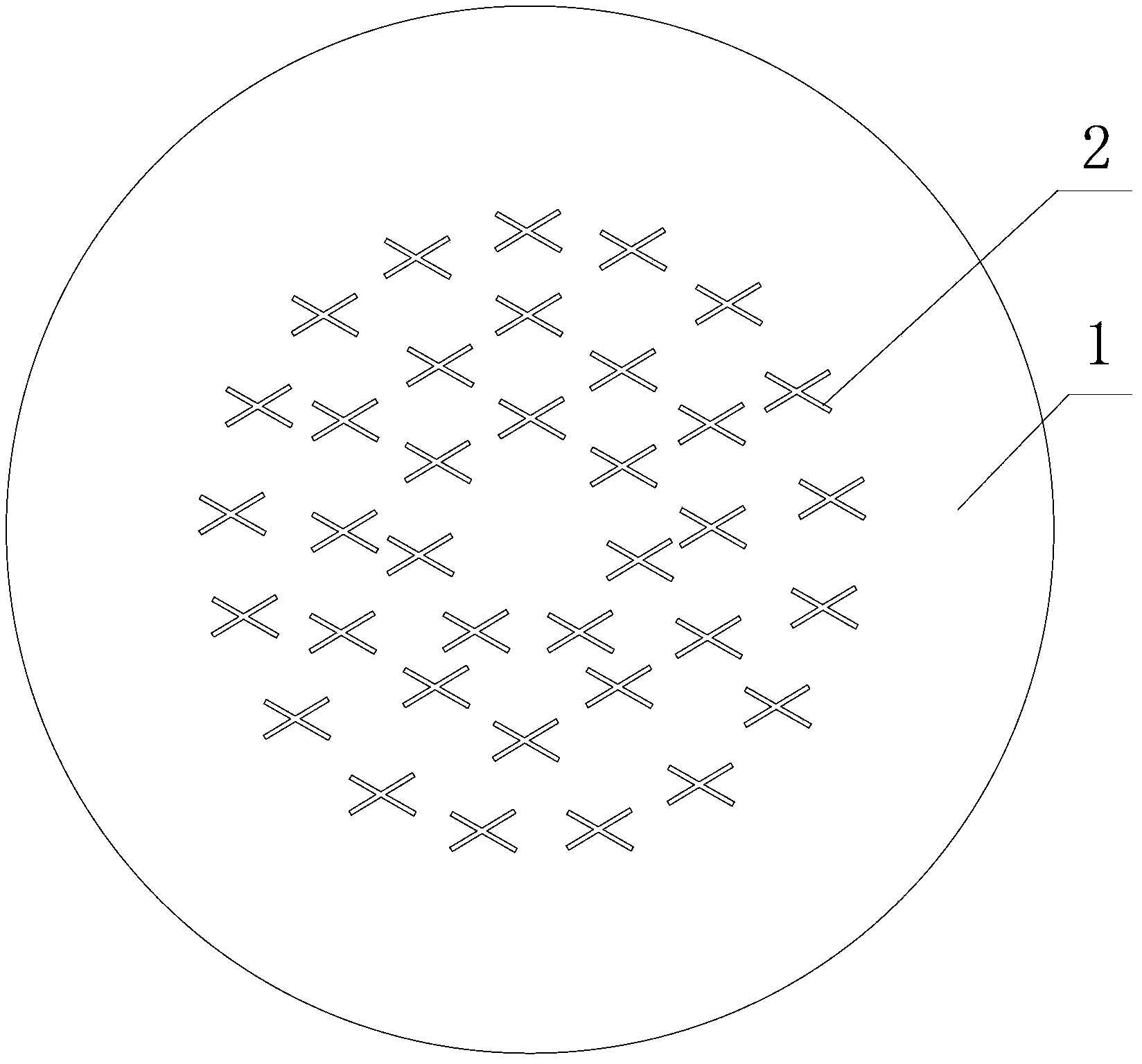

[0010] As shown in Fig. 1, a kind of " X " type microporous spinneret comprises spinneret plate surface 1, and spinneret plate surface 1 is provided with spinneret microhole 2, and one side of spinneret microhole 2 is for The feed port, the other side is the discharge port, the shape of the spinneret plate surface 1 is circular, the shape of the spinneret microholes 2 is "X", the number of microholes is 30-40, and the number of microholes is preferably 36 . The middle angle of the "X" type spinneret microhole is 110°~130°, which can significantly reduce the stagnation phenomenon during the flow in the melt microhole. On the spinneret plate surface 1, the leaf width of the "X"-shaped spinneret microholes 2 is 0.1-0.15 mm, and the ratio of leaf length to leaf width is 12-18. The described spinneret microholes 2 are arranged in a three-layer concentric c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leaf width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com