Differential linkage device of washing machine

A linkage device and washing machine technology, which is applied to washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of high manufacturing cost and complex structure, achieve obvious differential effect, fast and accurate control, and reduce manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

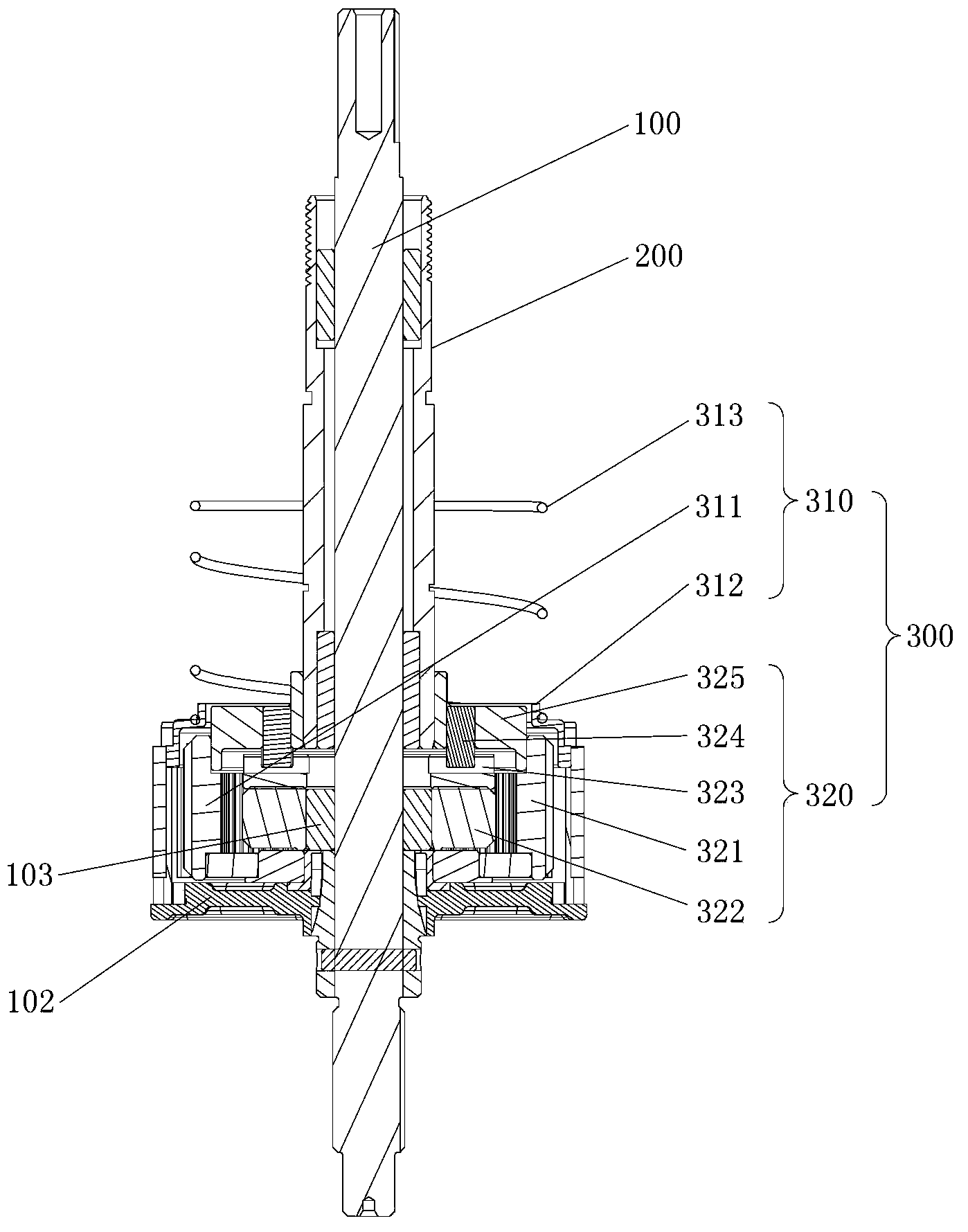

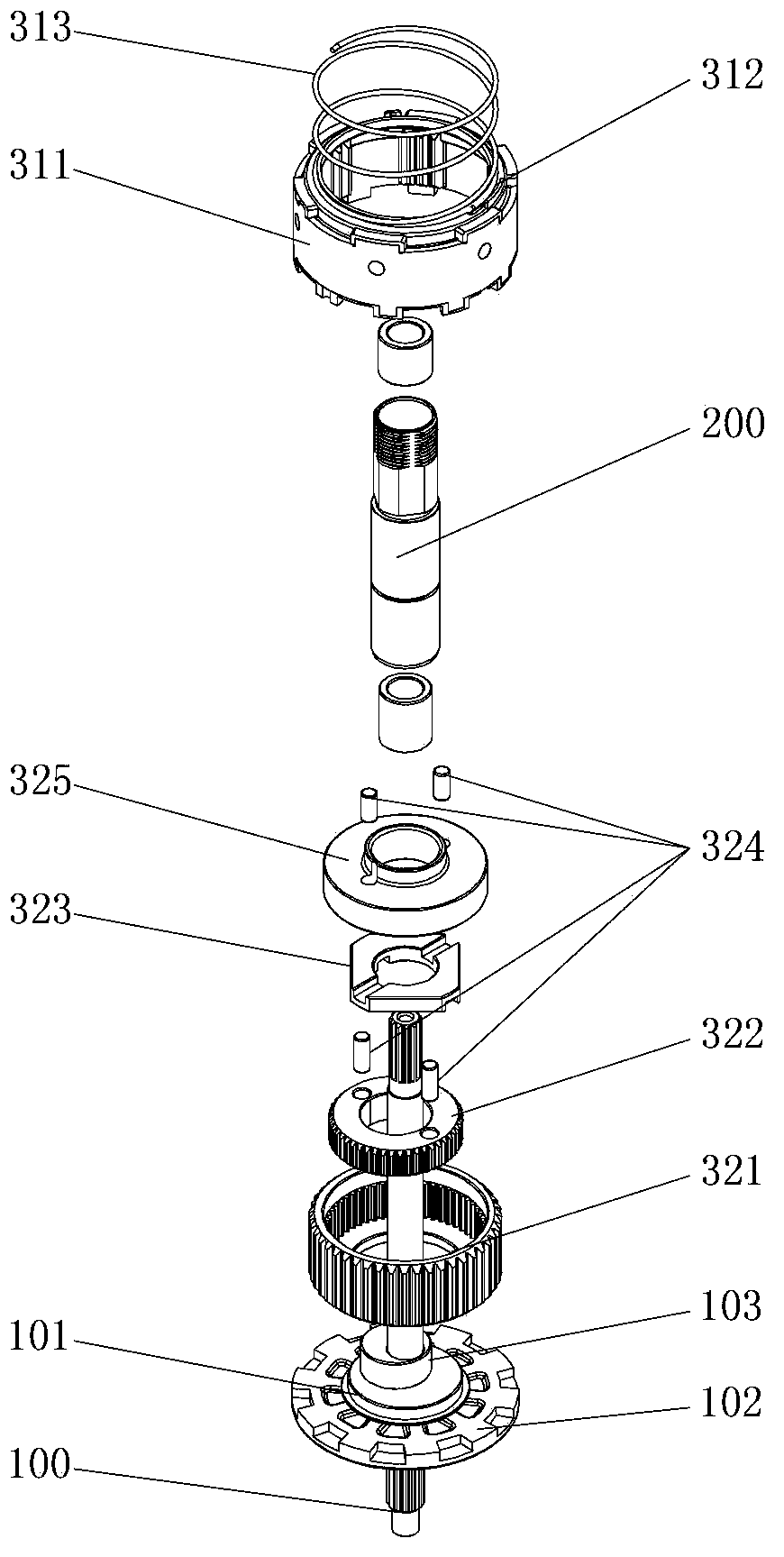

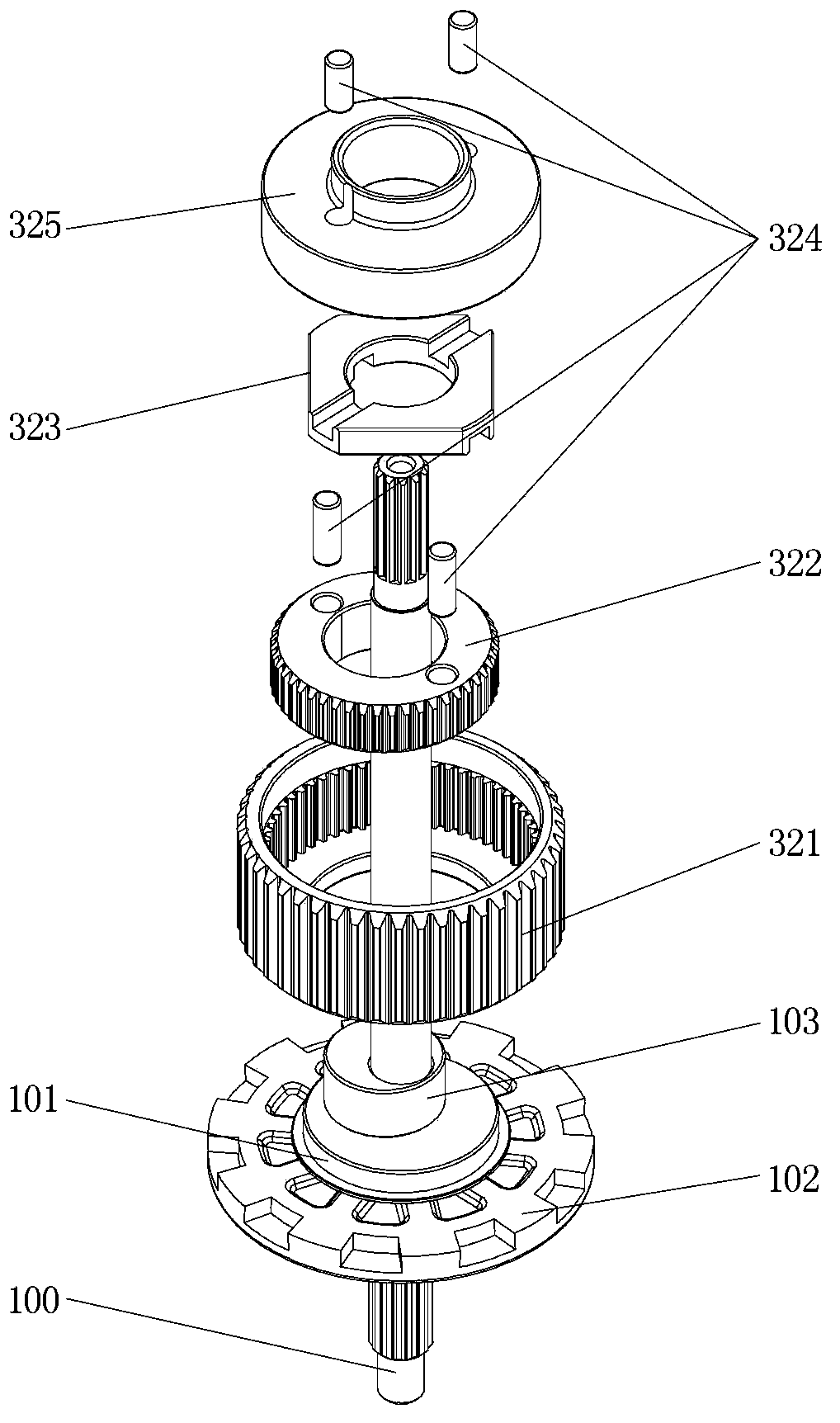

[0021] See Figure 1 to Figure 6 , the present invention has a drive shaft 100 and a drive sleeve 200, the drive shaft 100 is rotatably arranged in the drive sleeve 200, and a clutch linkage mechanism 300 is provided between the drive shaft 100 and the drive sleeve 200; the clutch linkage mechanism 300 has an electromagnetic The clutch assembly 310 and the Oldham differential assembly 320; the drive shaft 100 is sequentially fixed with a circular eccentric block 103, a limit boss 101 and a slot plate 102 from top to bottom; the drive shaft 100 passes through Oldham differential assembly 320; the Oldham differential assembly 320 has a ring gear 321, a gear 322, an Oldham 323, four pin shafts 324 and a gland 325; an eccentric block is provided in the middle of the gear 322 103 matching through holes; the diameter of the gear 322 is smaller than the diameter of the ring gear 321, the gear 322 is sleeved on the eccentric block 103, and is arranged in the ring gear 321 to mesh with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com