Split plunger device for non-shut-in continuous production

A split-type, plunger technology, which is used in the production of fluids, wellbore/well components, and earth-moving drilling, etc., can solve the problems of short plunger stroke, damage to the wellhead blowout preventer, and reduce the production efficiency of gas wells. The effect of bottom effusion, improving production efficiency and increasing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

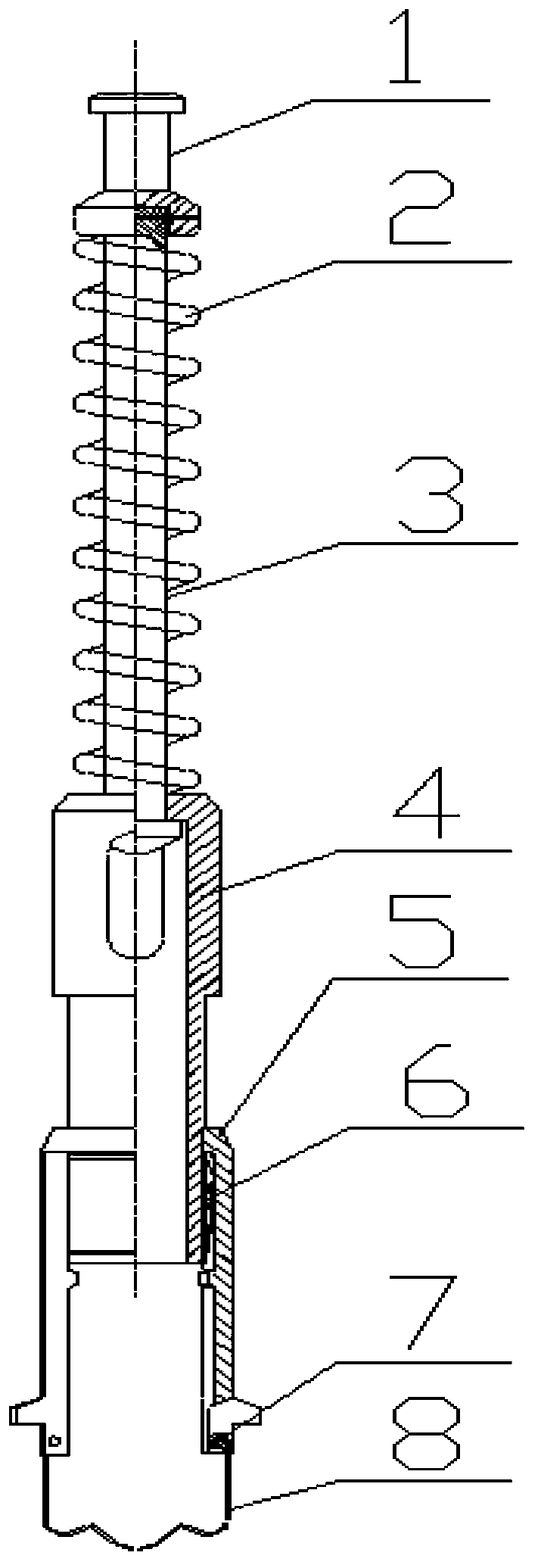

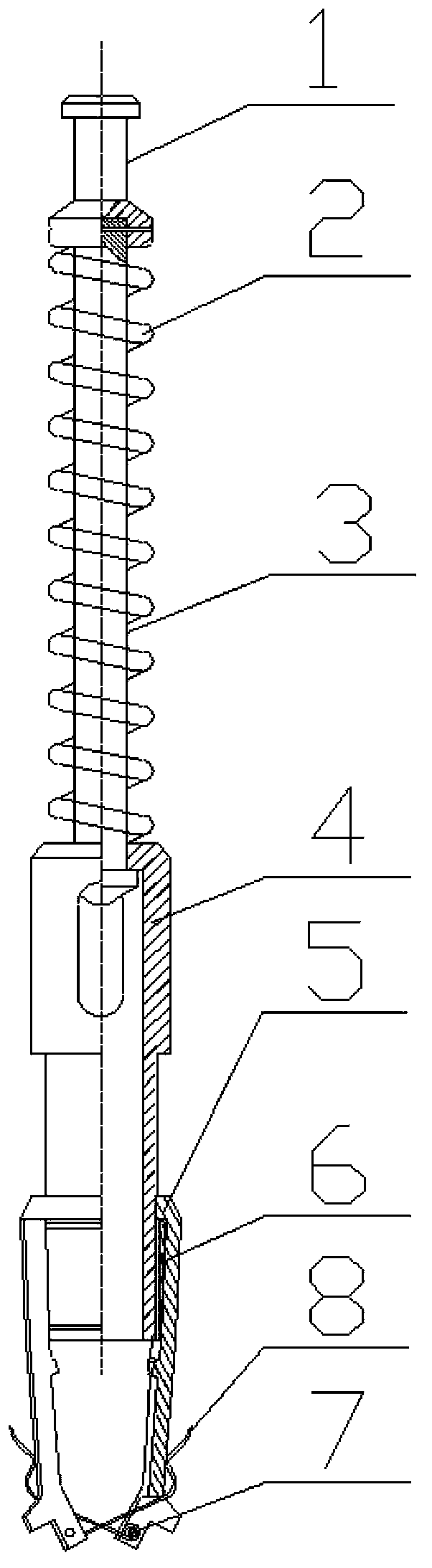

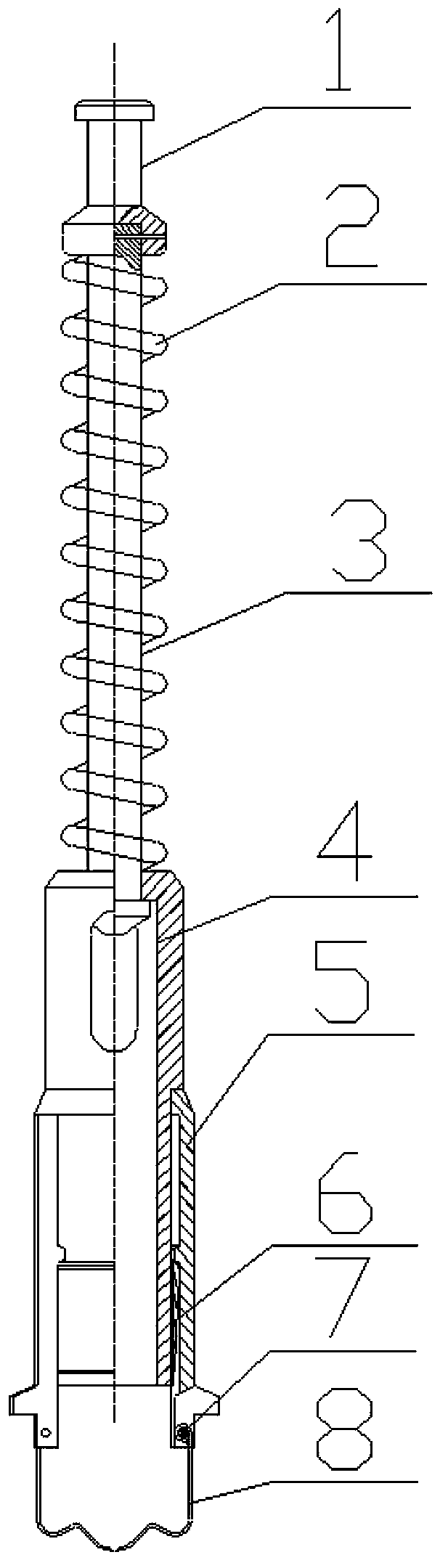

[0019] The split plunger device for continuous production without shutting down the well includes three parts: downhole buffer device, split plunger and wellhead buffer device:

[0020] The downhole buffer device is composed of a fishing head 1, a buffer spring 2, a connecting shaft 3, a guide tube 4, a seat seat 5, a locking sleeve 6, a steel wire clamp spring 7 and a pin shaft 8; the fishing head 1 is threadedly connected " T”-shaped connecting shaft 3, buffer spring 2 and guide tube 4 are set on the connecting shaft 3 in sequence, two oval through holes are symmetrically arranged on the wall of the upper part of the guide tube 4, and the bottom end of the guide tube 4 is threaded. The tapered locking sleeve 6, the outside of the locking sleeve 6 is the seat 5 on the lower diameter reducing tube of the sleeve guide tube 4; the inner wall of the seat 5 is provided with a shoulder, and the outer wall is symmetrically provided with slip wing grooves, Steel wire jumper 8 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com