Fracture seepage experimental instrument for coal mine

An experimental instrument and seepage technology, which is used in instruments, scientific instruments, permeability/surface area analysis, etc., can solve the problems of difficult sealing between gaskets and coal samples, affecting the accuracy of experiments, and large errors in seepage experiments, so as to improve the sealing performance. , improve reliability and comparability, reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

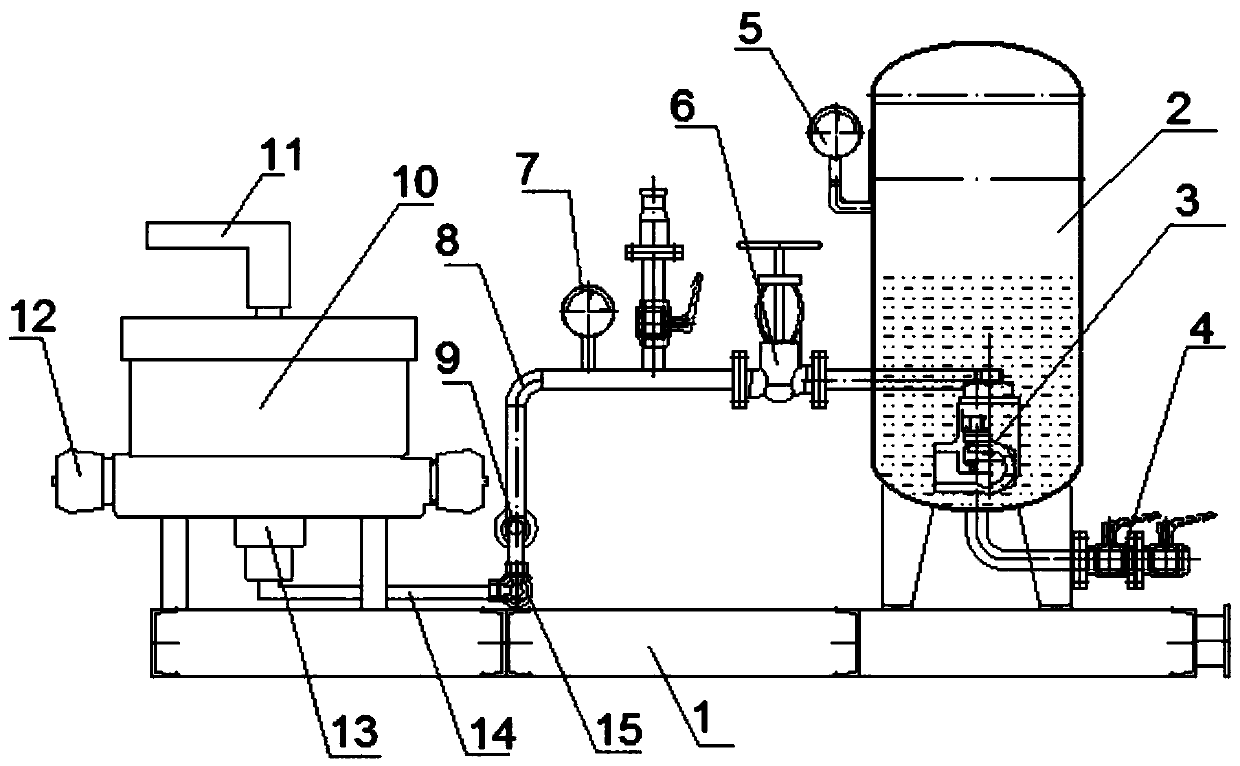

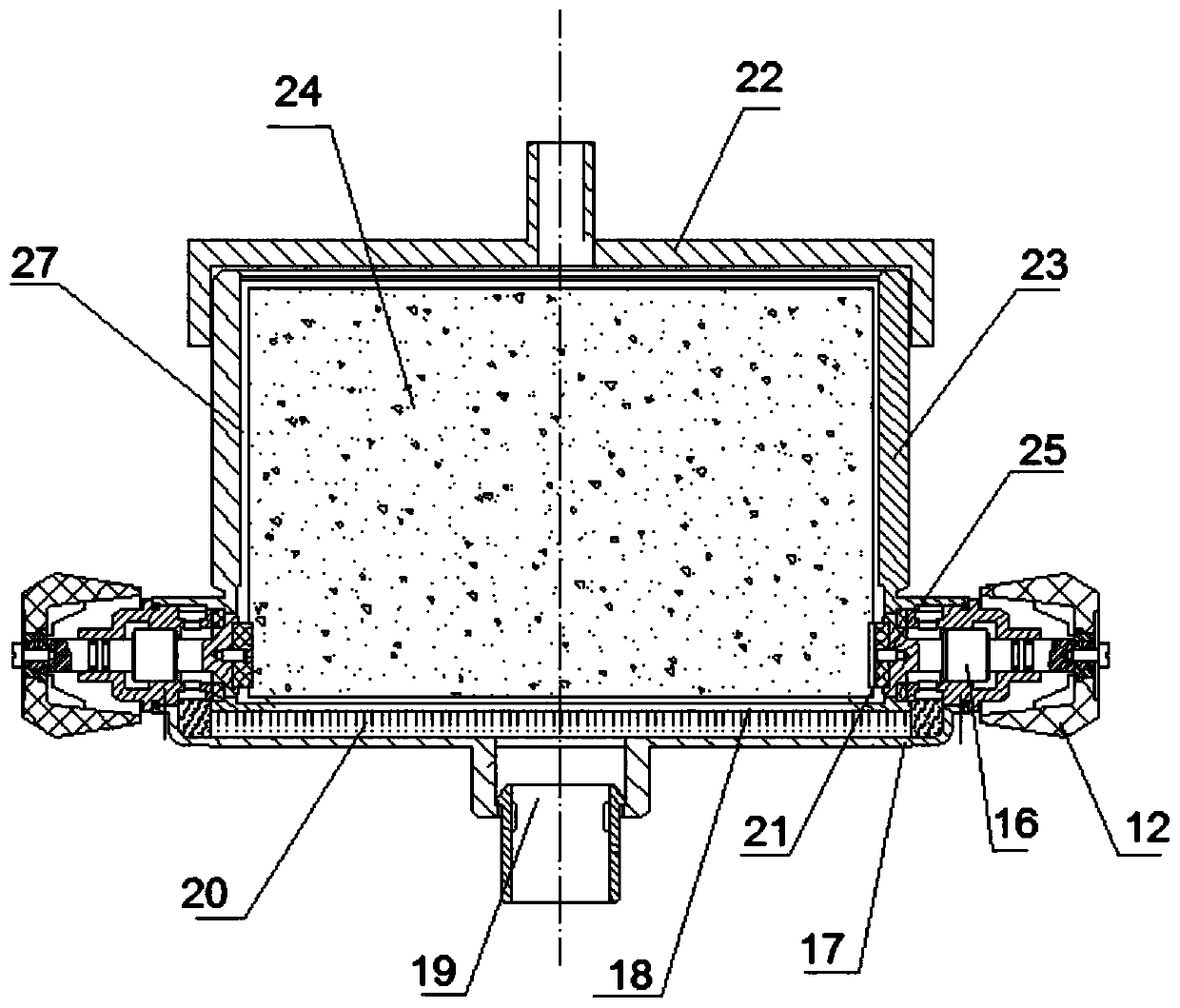

[0024] see Figure 1~4 , in an embodiment of the present invention, a fissure seepage test instrument for coal mines includes a seepage liquid supply mechanism, a supply main pipe 9, a seepage test cylinder assembly 10 and a liquid outlet pipe 11, wherein the output end of the seepage liquid supply mechanism is connected to To the supply main pipe 9, it is characterized in that a plurality of the seepage test tube assemblies 10 are connected in parallel to the supply main pipe 9, and the sealed connection in the seepage test tube assembly is provided with a coal sample 24 to be tested ;

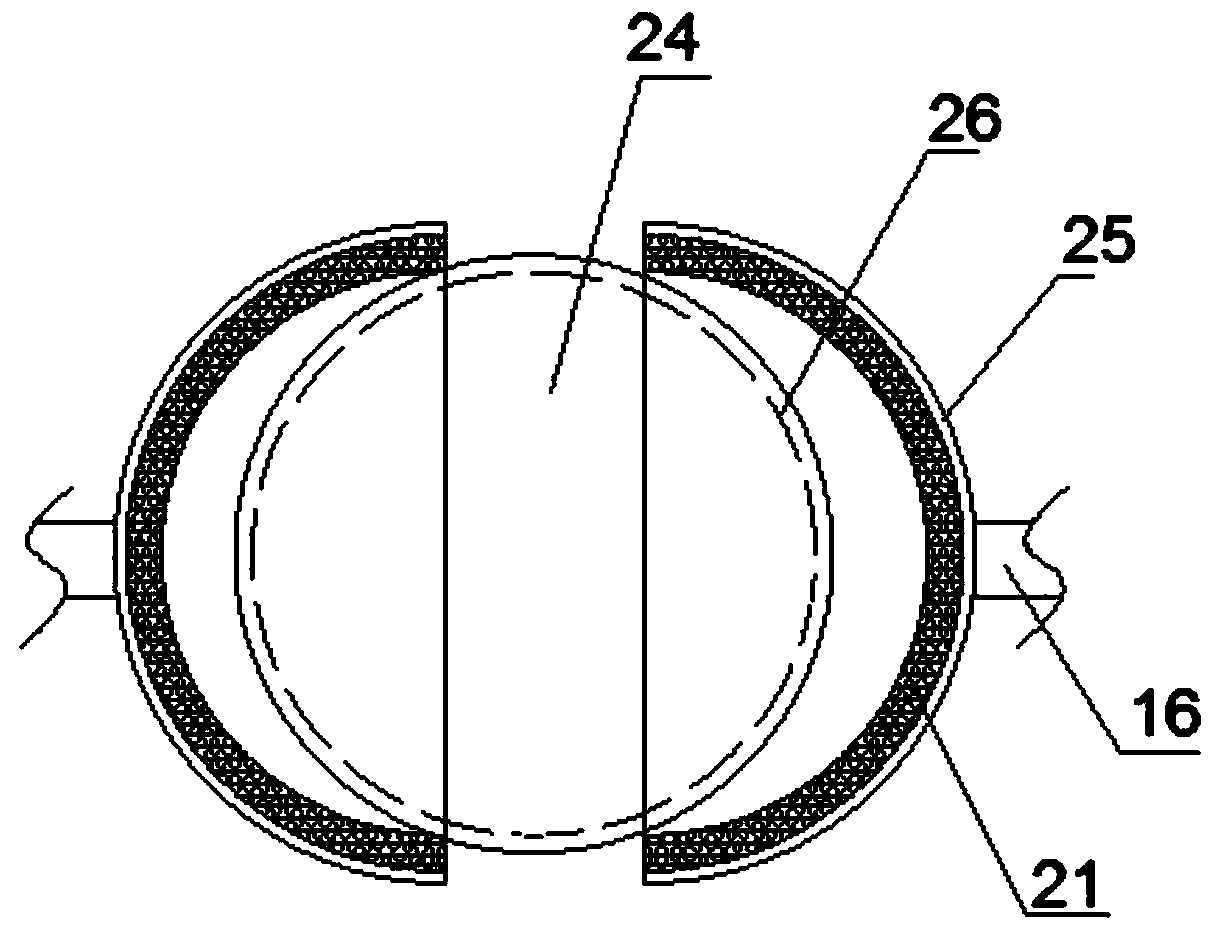

[0025] The outer wall of the coal sample 24 is in sealing connection with the inner wall of the seepage test cylinder assembly, and the lower end of the seepage test cylinder assembly is a seepage liquid inlet joint 19 connected with the supply main pipe, the The upper end of the seepage test cylinder assembly communicates with the liquid outlet pipe 11, and a pressure equalizing film 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com