Dry-type wide tunnel dust settling vehicle with water recycling function

A dust truck and dry technology, which is applied in dust prevention, safety devices, mining equipment, etc., can solve the problems of increased danger, environmental pollution in tunnels, poor dust scattering effect, etc., and achieve low water consumption and significant dust reduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

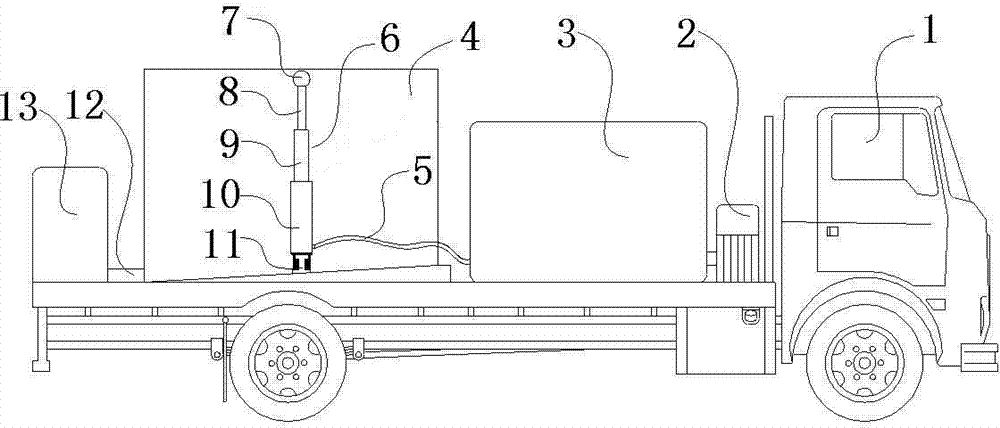

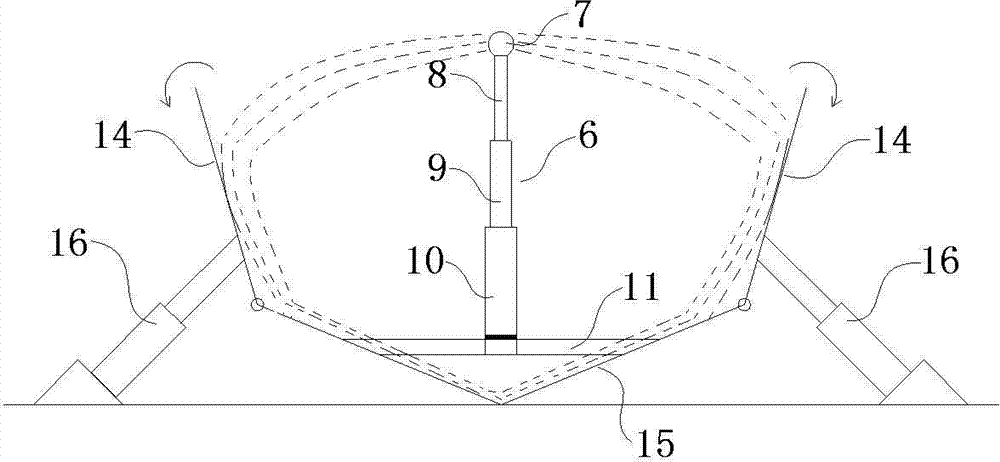

[0022] Example: such as figure 1 As shown, this embodiment specifically relates to a dry-type wide-width tunnel dust suppression vehicle with circulating water. The dust suppression vehicle uses the existing sprayer function, combined with the moving vehicle body 1, to provide power for the sprayer with the power of the moving vehicle body 1, and Utilize the enclosure body 4 on the periphery of the sprayer to block the spray precipitation and drain it into the waste water filter box 13, and then reuse it after being filtered by the filter in it, so as to achieve the purpose of moving dry dust suppression and circulating water.

[0023] Such as figure 1 Shown, the rear portion of mobile car body 1 is a flat platform, is installed with pressure equipment 2, water tank 3, enclosure body 4, the sprayer (being spray bar 6 that is positioned at enclosure body 4) in turn on flat platform And spray head 7) and waste water filter box 13.

[0024] Such as figure 1 As shown, the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com