Vane type hydraulic motor

A hydraulic motor and vane technology, applied in the field of hydraulic motors, can solve problems such as poor sealing performance, insufficient output torque, and short life, and achieve the effects of easy processing, compact structure, and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

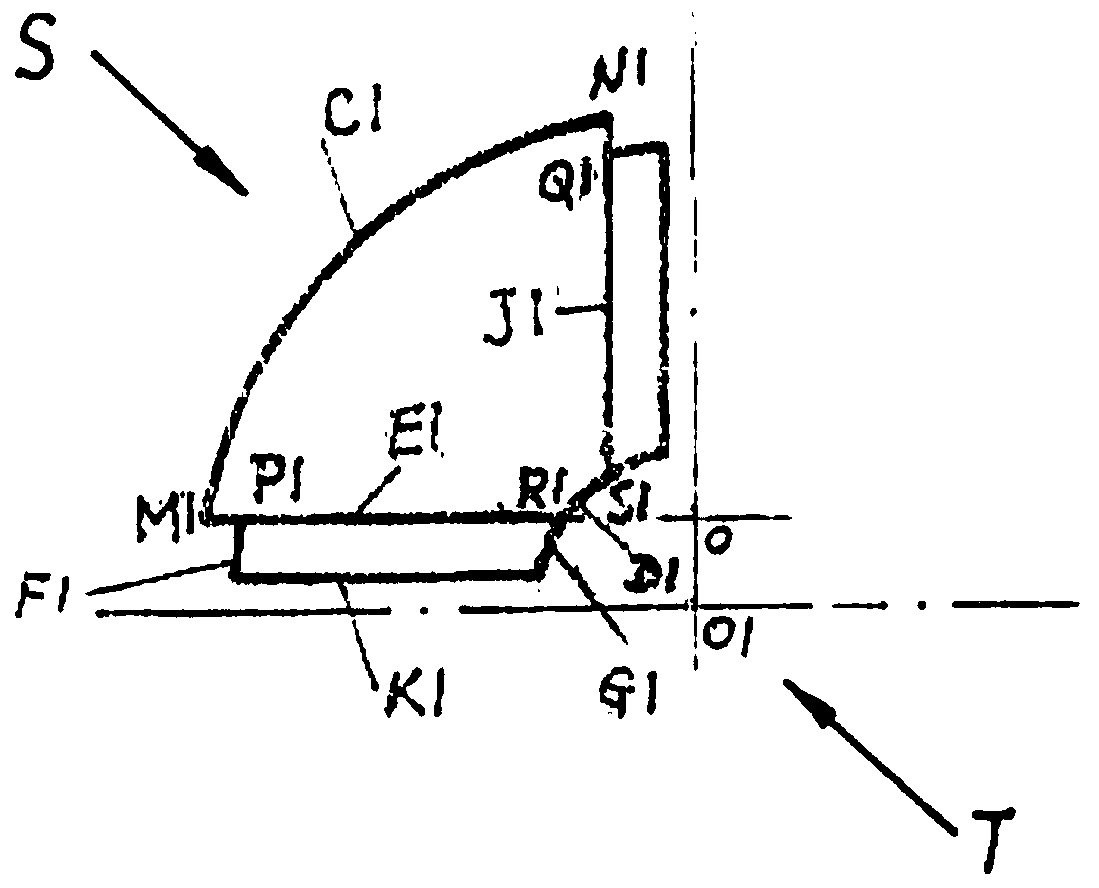

[0037] The structure of the present invention is as Figure 14 As shown, the rotor 2 is located in the center, the housing 1 is located outside, the oil distribution cone 5 is located in the hollow circular table at both ends of the rotor 2, the blade 3 is placed in the hollow ring (guide groove) at the opposite corner of the housing 1, and is also located in the In the groove of the rotor 2, and form an angle with the rotor 2, a plane of the vane 3 fits with the side of the round table of the oil distribution cone 5, and the sealing strip 4 is located between the rotor 2 and the vane 3, and one side of the plane is in contact with the rotor 2 The one side of the circular table surface is bonded to the circular table surface E1 of the blade 3, and the spacer 6 is located in the hollow ring at the opposite corner of the housing 1, just filling the housing 1, the blade 3, the rotor 2 and the sealing strip 4 vacancy formed.

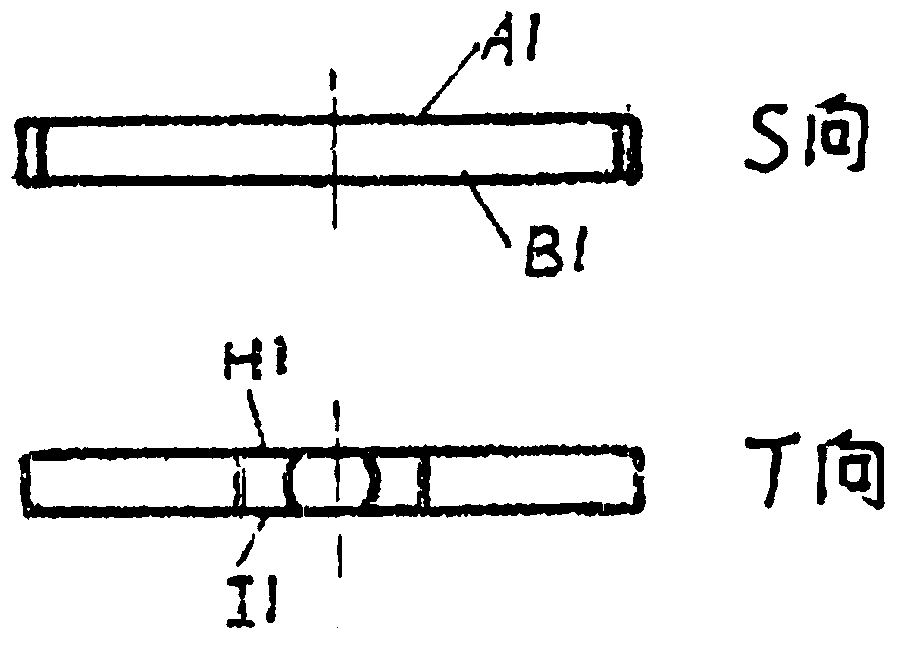

[0038] figure 1 and image 3 Shown are the shapes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com