Hydraulic drive oil extraction device

A technology of hydraulic drive and oil production device, applied in the fields of fluid production, earthwork drilling, machine/engine, etc., can solve the problems of oil pipe perforation and sucker rod breakage, so as to reduce breakage, avoid wear and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

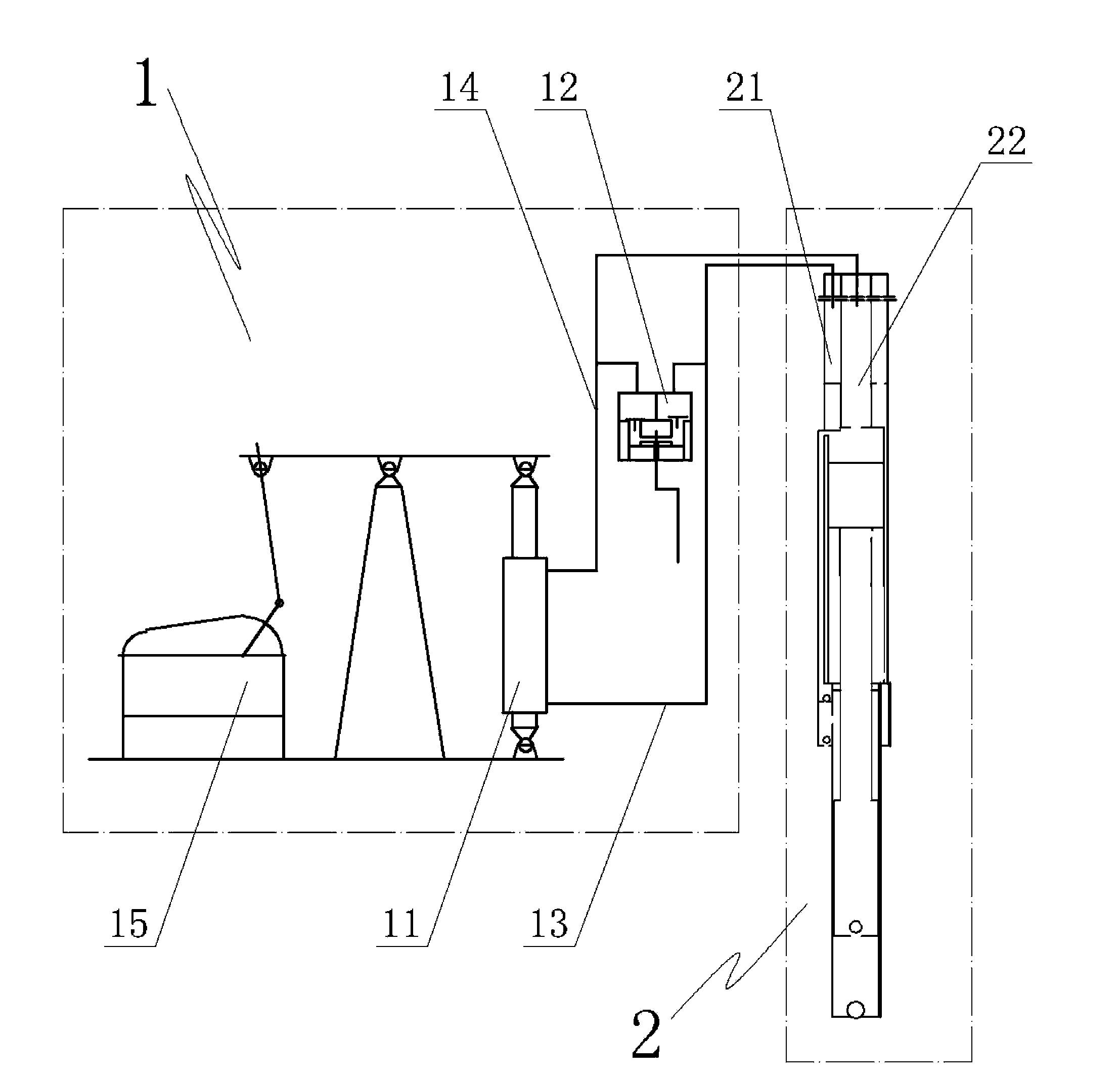

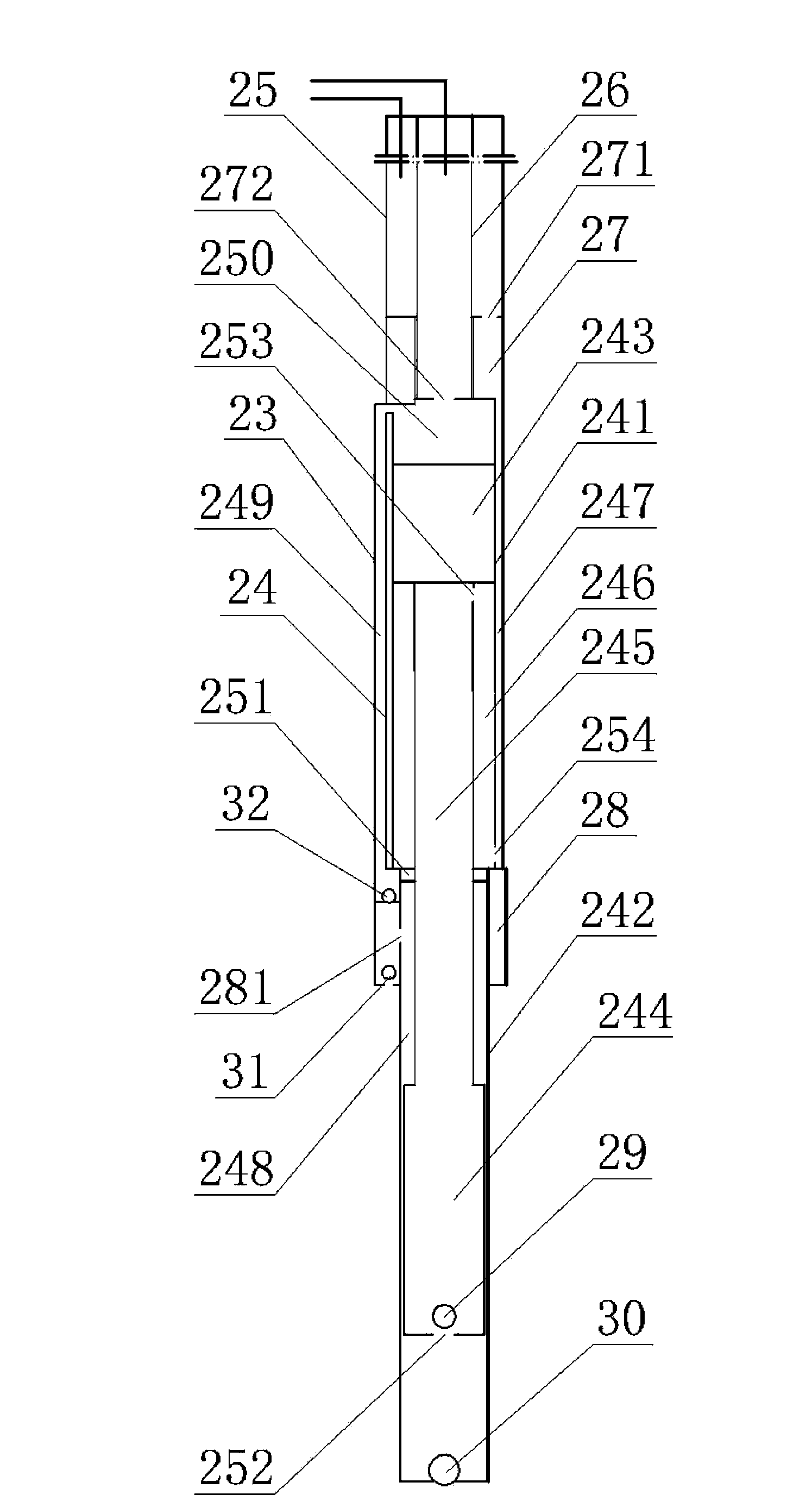

[0027] This embodiment provides a hydraulically driven oil extraction device, see figure 1 , figure 2 with image 3 , the oil production device includes: a surface power system 1 and a downhole hydraulically driven double-acting oil well pump 2, the ground power system 1 provides hydraulic driving force for the downhole hydraulically driven double-acting oil well pump 2, so that the downhole hydraulically driven double-acting oil well pump 2 The relevant parts of the machine make up and down stroke reciprocating movements, so as to realize the extraction of the original liquid.

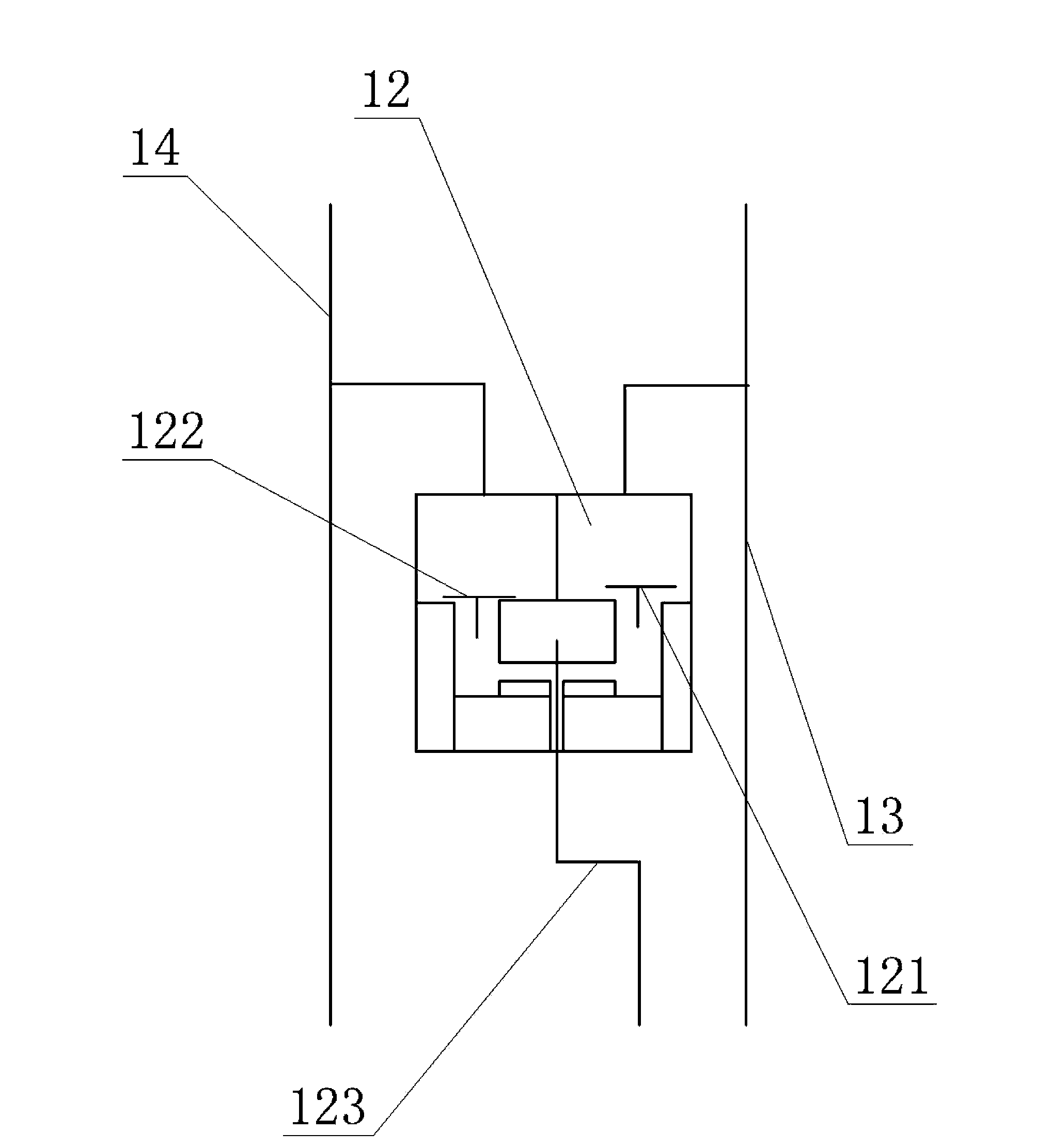

[0028] Wherein, the ground power system 1 includes a power hydraulic cylinder 11, a distribution valve assembly 12 and a four-bar linkage mechanism 15. Specifically, the first end of the power hydraulic cylinder 11 is fixed on the ground, and the first end of the power hydraulic cylinder 11 is connected to the four-bar linkage mechanism. The connecting rod mechanism 15 is hinged, and under the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com