Reinforcement type electromagnetic mechanical brake

A mechanical brake and booster technology, which is applied in the direction of brake type, axial brake, mechanical equipment, etc., can solve the problems of shortened life, etc., and achieve the effects of reducing brake temperature rise, low energy consumption, and good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

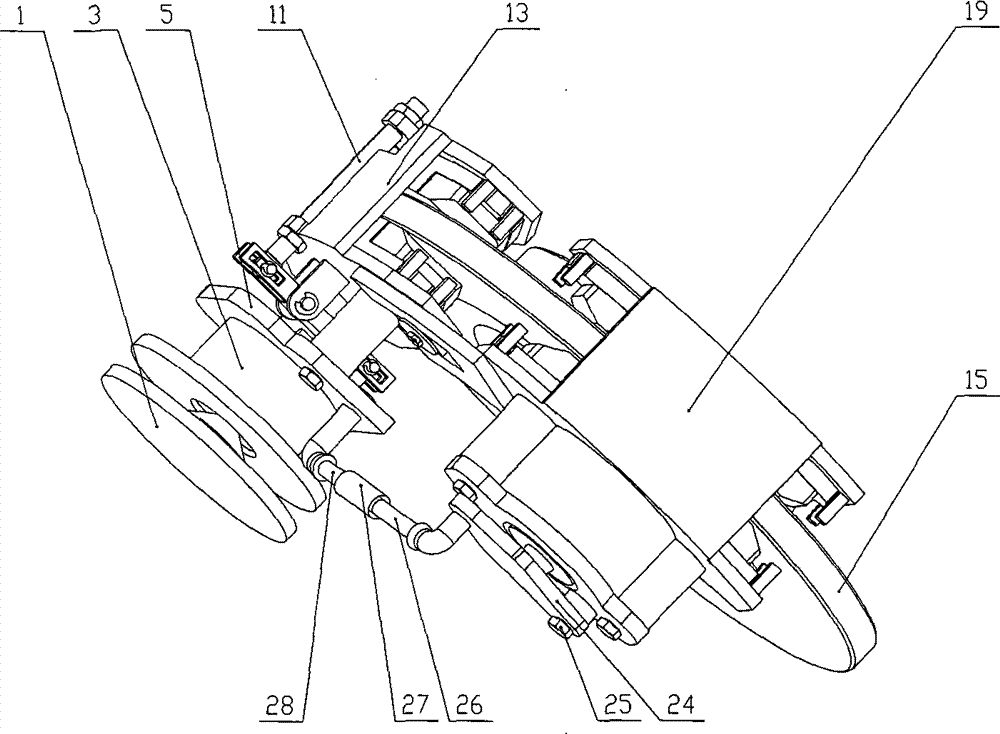

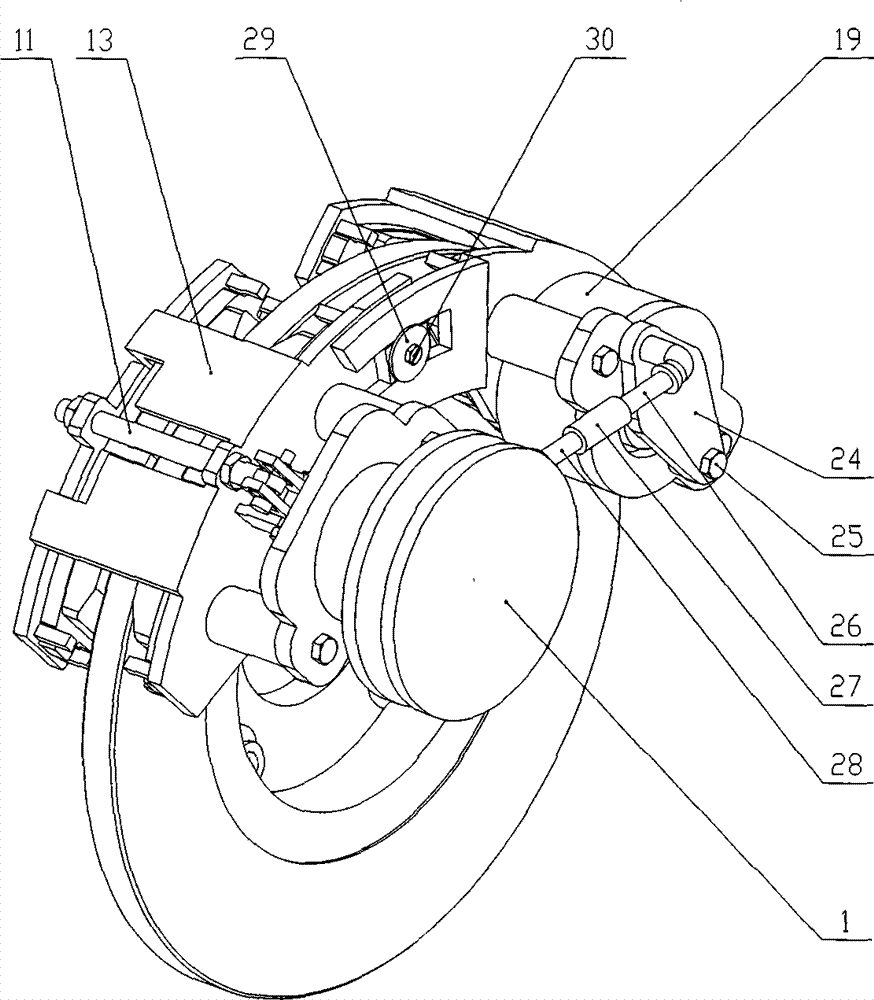

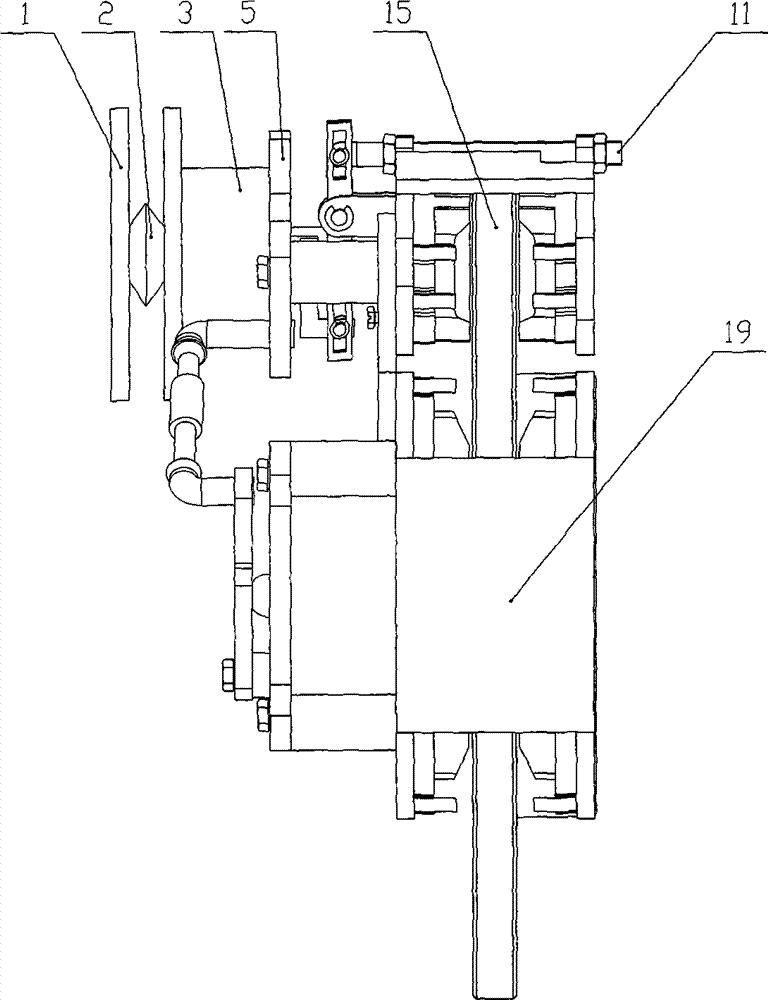

[0025] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode and in conjunction with the accompanying drawings.

[0026] A booster electromagnetic mechanical brake, consisting of a moving plate 1, a disc spring 2, a fixed casing 3, a coil 4, a first bracket 5, a mandrel push rod 6, a first pin assembly 7, and a second pin assembly 8. Swing arm 9, first nut 10, tension rod 11, second nut 12, first caliper 13, first friction plate 14, brake disc 15, second friction plate 16, third pin assembly 17 , the third friction plate 18, the second caliper 19, the fourth friction plate 20, the push cylinder 21, the second bracket 22, the thrust ball 23, the thrust plate 24, the positioning bolt 25, the first pull rod 26, the sleeve 27, the second The pull rod 28, the retaining ring 29, the bolt 30 and the extruded plate 31 are composed, the second caliper 19 is installed on the vehicle frame, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com