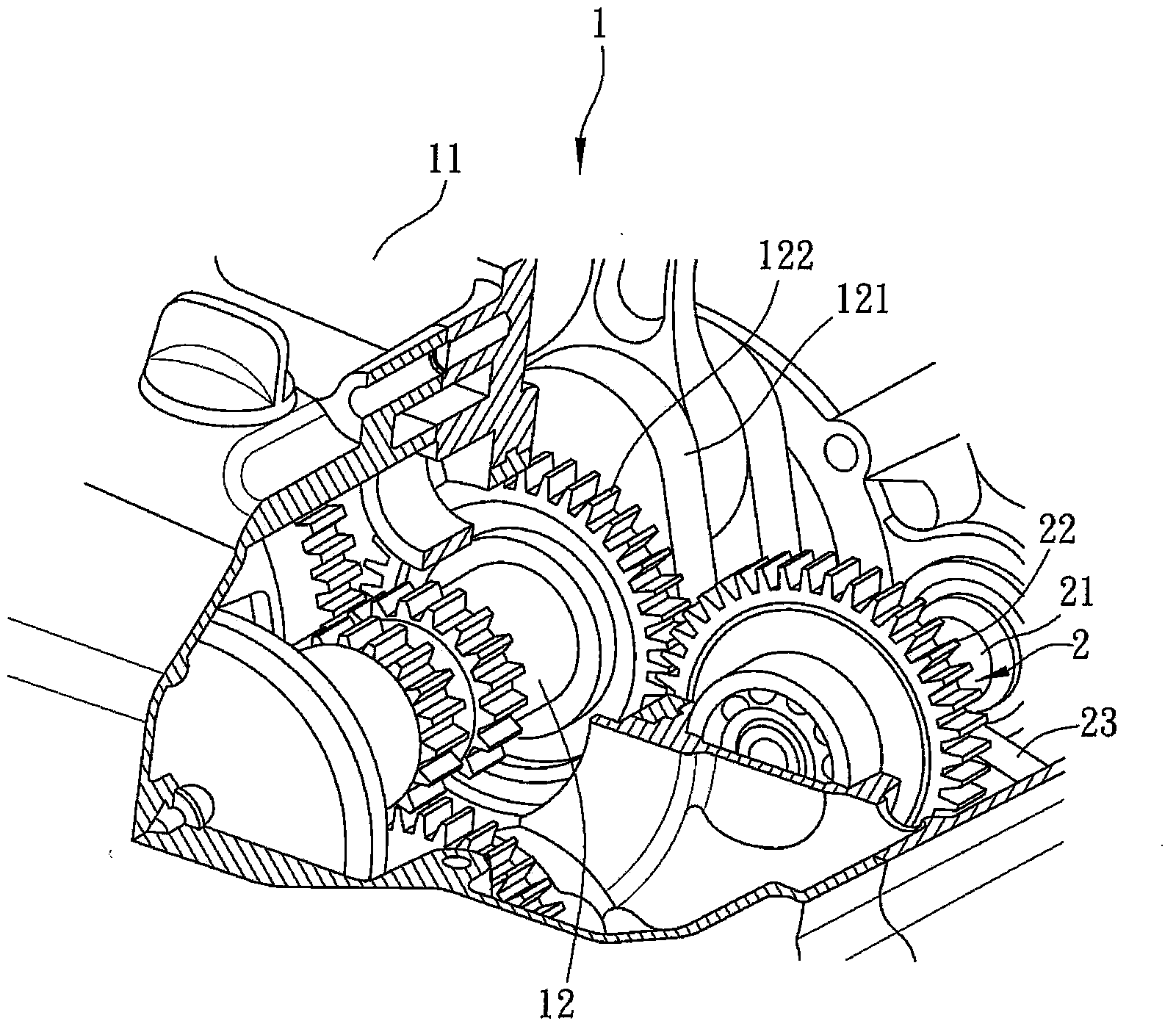

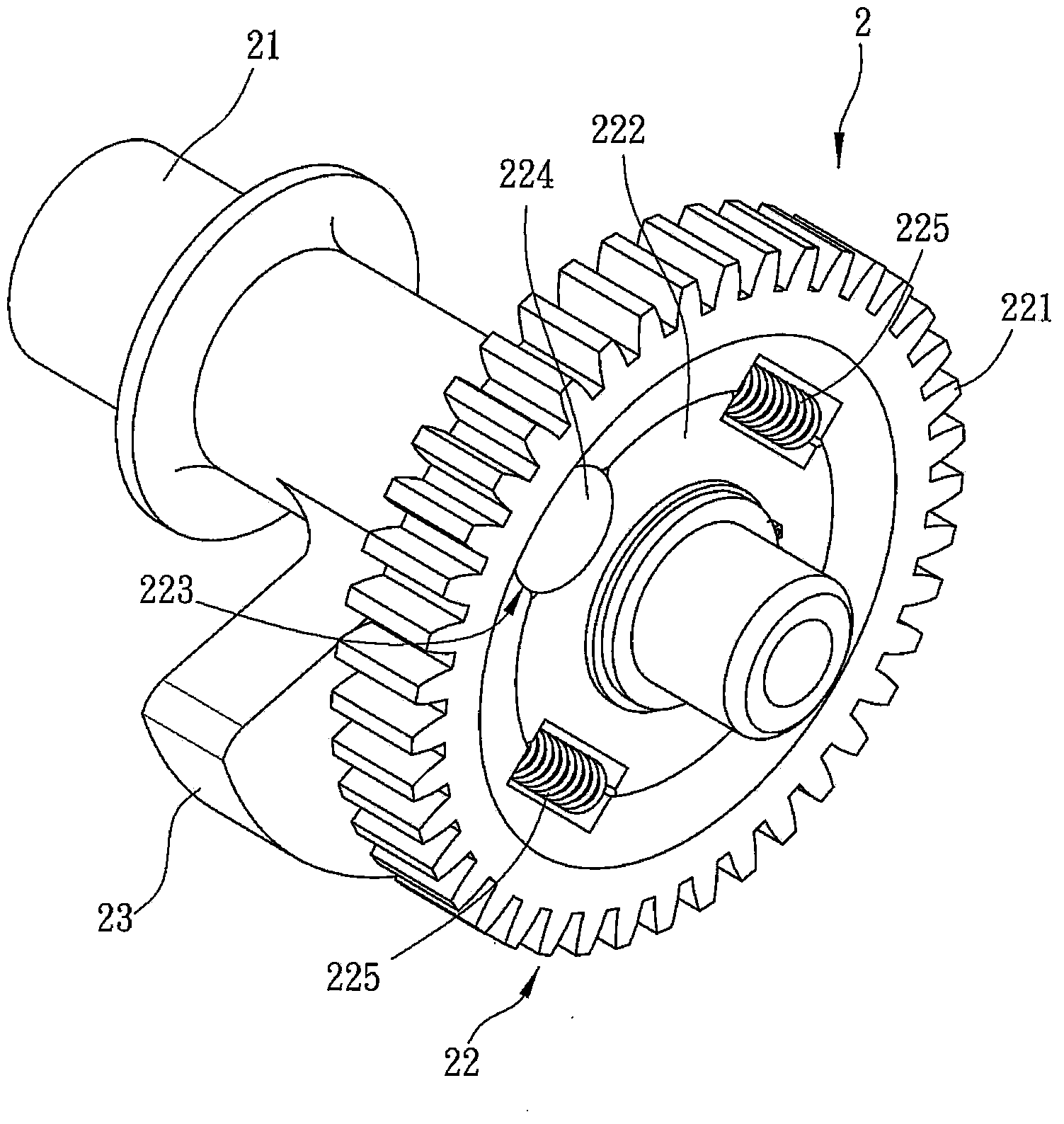

Gear mechanism for balance shaft of engine

A technology of gear mechanism and balance shaft, applied in belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problems of inability to drive, loss of buffer, manpower, material resource consumption, etc., to extend service life, eliminate backlash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the accompanying drawings.

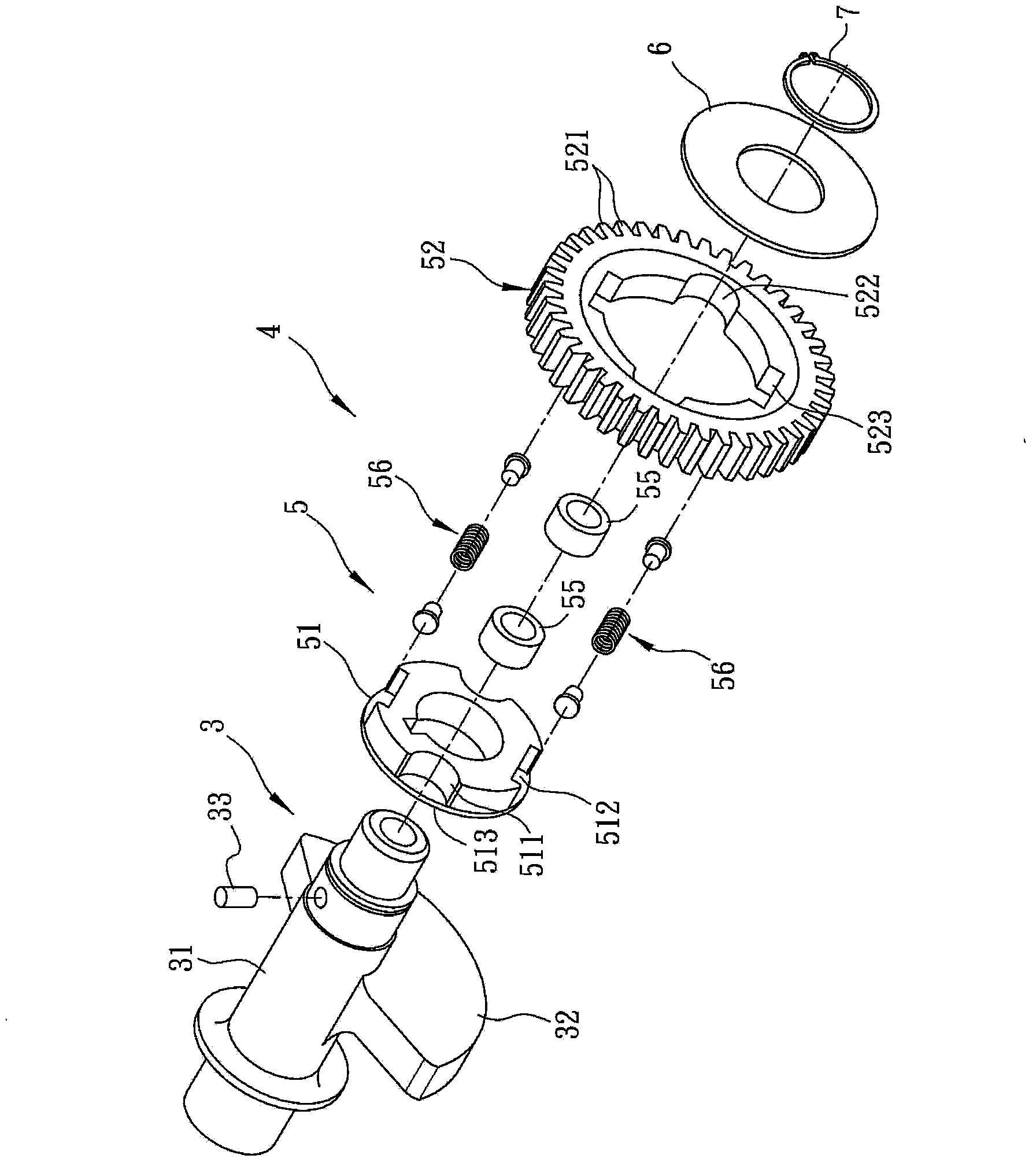

[0017] refer to image 3 and Figure 4 , which is a preferred embodiment of the gear mechanism 4 used for the balance shaft of the engine according to the present invention, the balance shaft 3 includes a shaft 31 and a counterweight 32 located on the shaft 31 . The gear mechanism 4 includes a driven gear set 5 set on the shaft 31, a fixed plate 6 covering the side of the driven gear set 5 opposite to the counterweight 32 and passing through the shaft 31, And a buckle 7 buckled on the shaft 31 and engaged with the fixing piece 6 . In this embodiment, the buckle 7 is a C-shaped buckle, but it is not limited thereto.

[0018] The driven gear set 5 includes an inner ring 51 fixed on the shaft 31 , an outer ring 52 surrounding the inner ring 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com