Novel stop valve

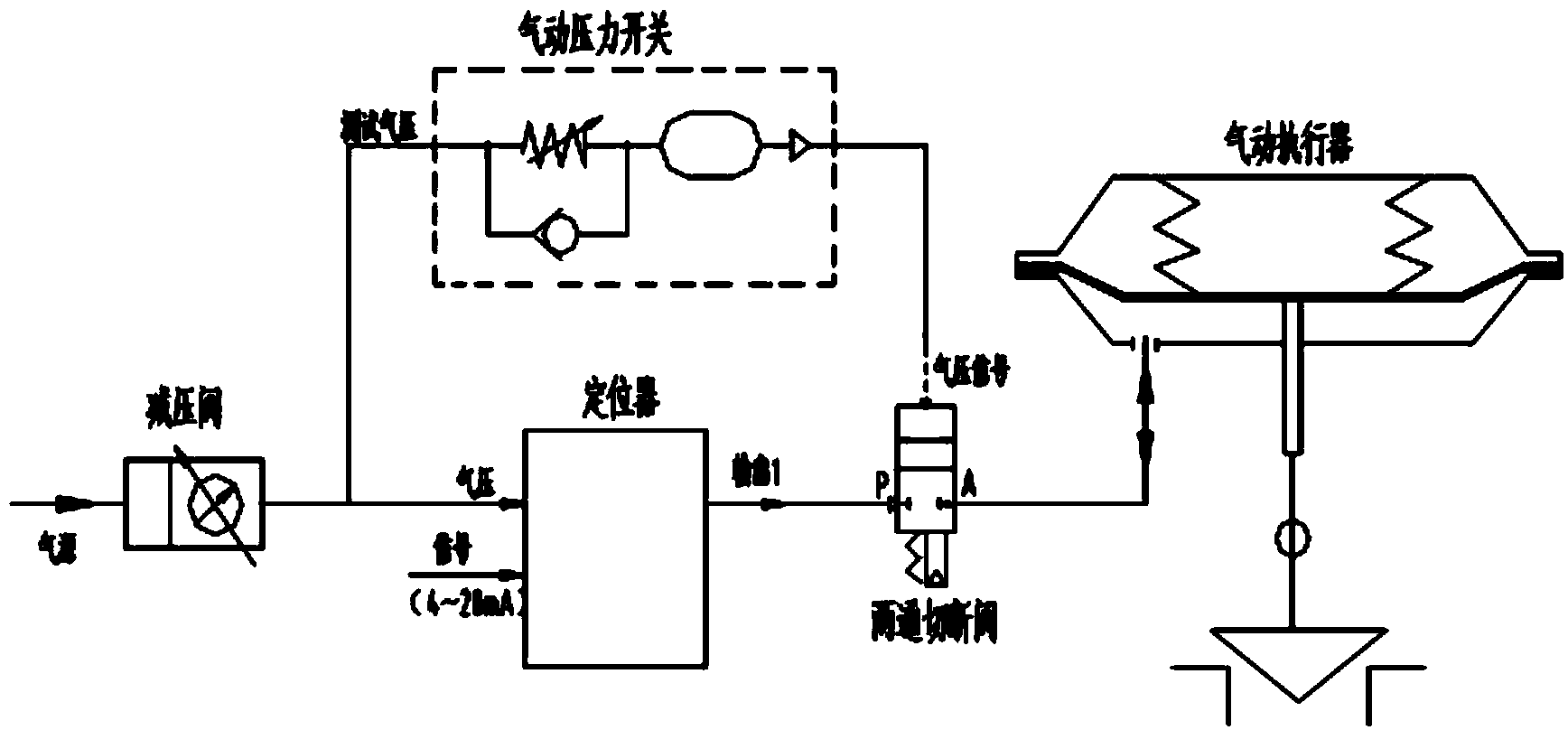

A cut-off valve, a new type of technology, applied in the direction of valve details, safety valves, balance valves, etc., can solve the problems of complicated connection and debugging, high cost, and large overall shape and volume, and achieve low manufacturing cost, low cost, and pressure setting. flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

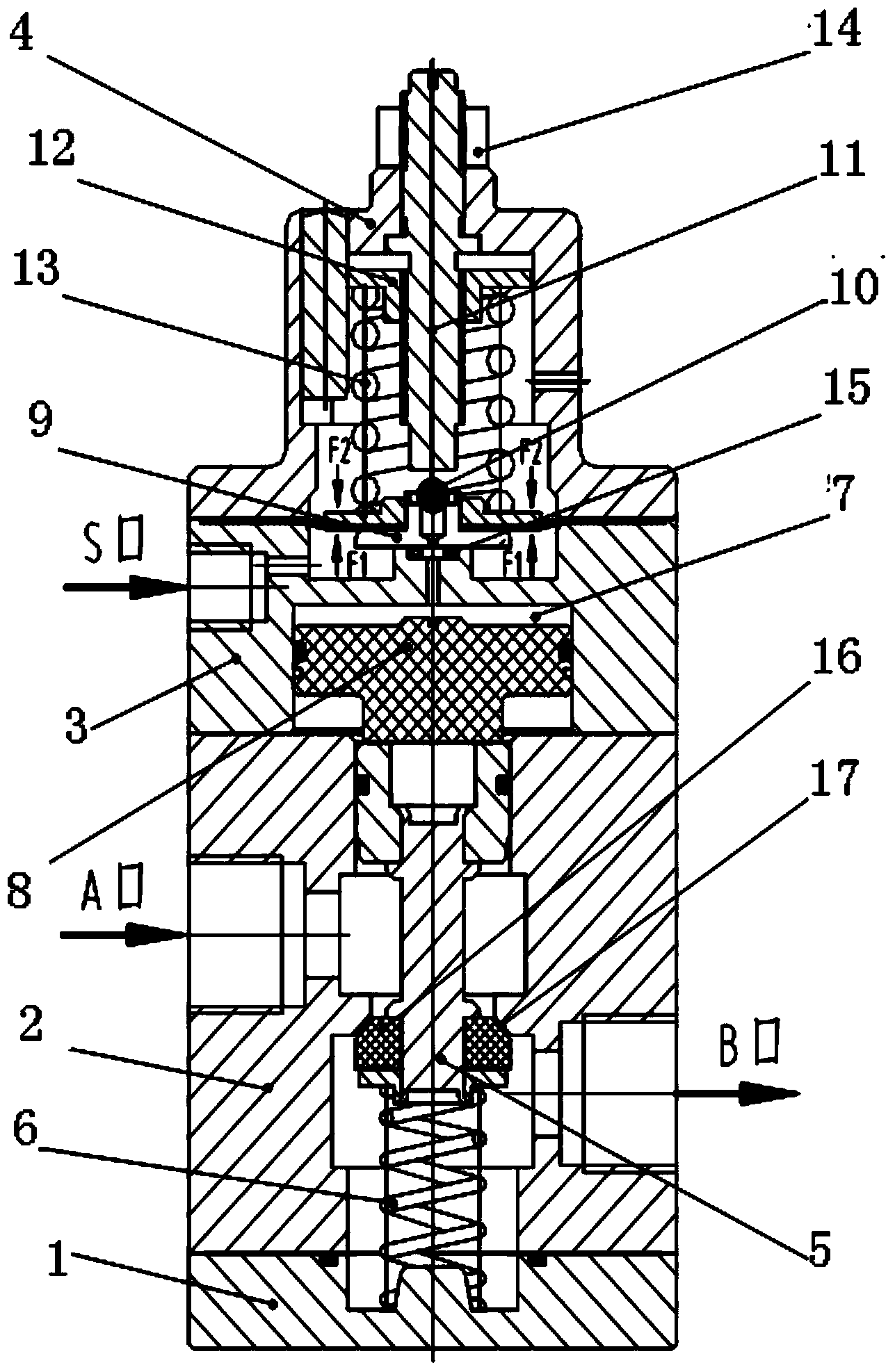

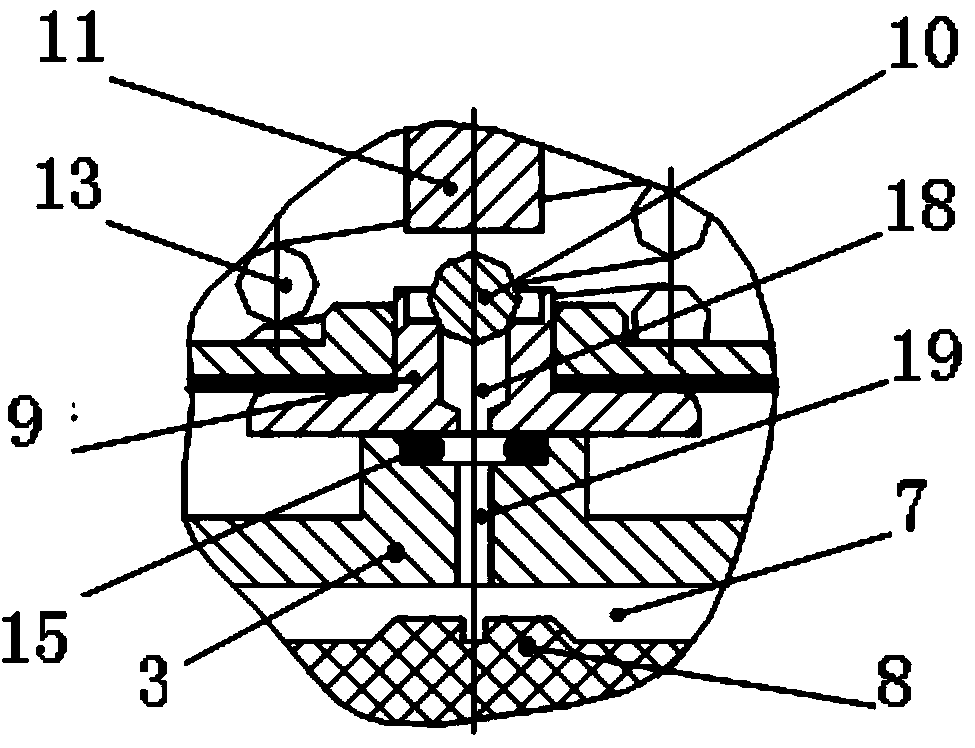

[0018] like figure 2 , 3 , 4, and 5, the present invention is a new cut-off valve, including a base 1, on which a reversing chamber 2, a piston chamber 3 and a pressure regulating chamber 4 are sequentially installed on the base 1, wherein the reversing chamber 2 are respectively opened with an inlet (namely A port) and an outlet (namely B port), a valve core part 5 is installed in the reversing chamber 2, the lower end of the valve core part 5 is connected with the base 1 through a return spring 6 and its The upper end is connected with the air control piston 8 installed in the air pressure chamber 7 in the piston chamber 3 .

[0019] Wherein, a diaphragm tray part 9 is installed in the pressure regulating chamber 4, and an exhaust hole 18 is arranged in the middle of the diaphragm tray part 9. Cavity 7 communicates, and a steel ball 10 is installed on the upper end of the exhaust hole 18, and a detection air pressure port (namely S port) is also opened on the aforemention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com