Cable bridge with heat dissipation function

A cable tray, functional technology, applied in the direction of pipe supports, electrical components, pipes/pipe joints/pipes, etc., can solve the problems of low strength, easy to scratch the arm, poor heat dissipation effect, etc., to achieve high strength, good heat dissipation effect, The effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

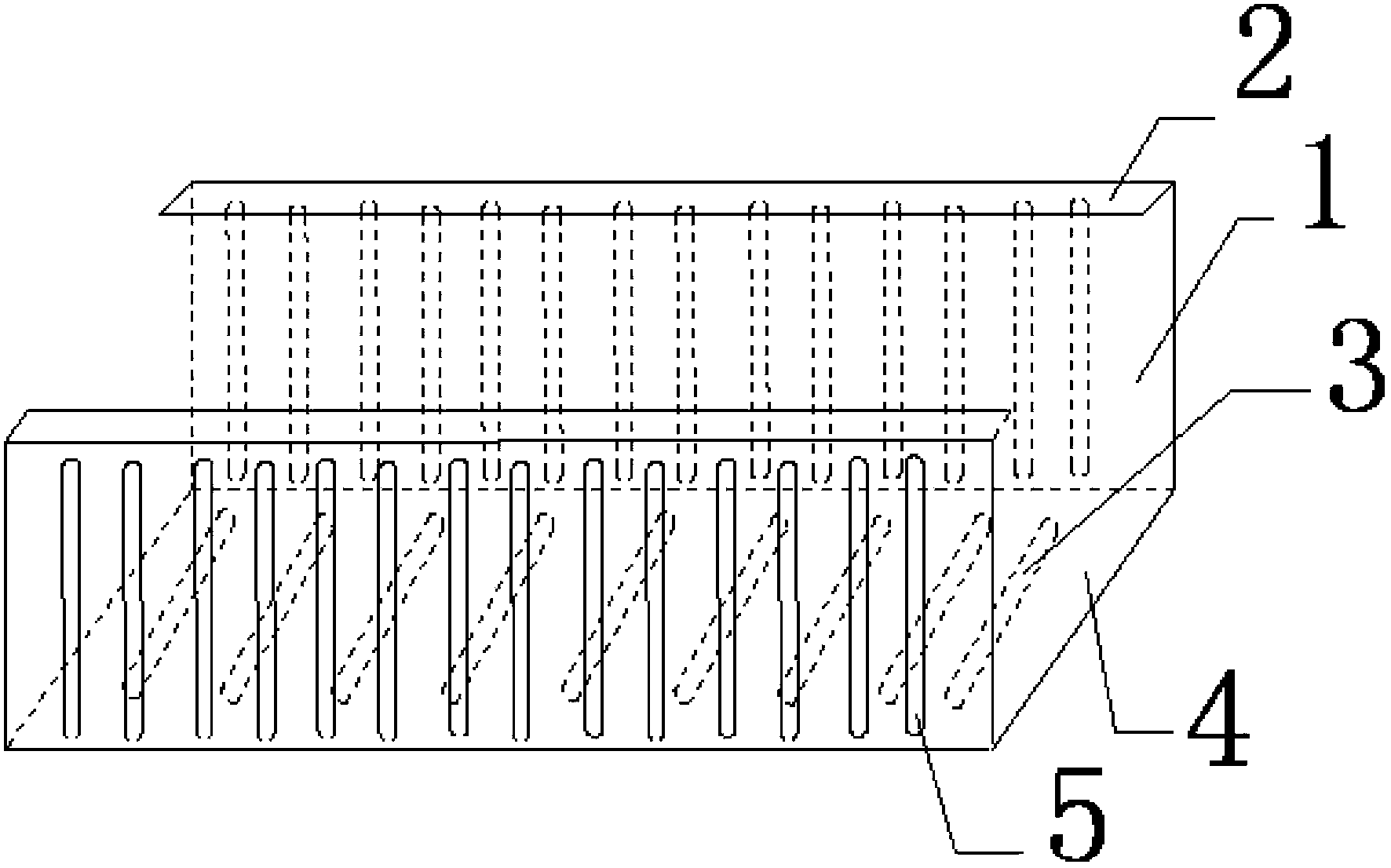

[0012] Such as figure 1 As shown, a cable tray with heat dissipation function of the present invention includes a side plate 1 and a bottom plate 4. It is characterized in that: the top of the side plate 1 is provided with a folded edge 2, and the direction of the folded edge 2 is inward, and the Several protrusions 3 are provided on the bottom plate 4 , and several grooves 5 are evenly distributed on the side plate 1 . There are several through holes at the position where the protrusion 3 is not provided on the bottom plate 4 . The through hole is circular, square or oval. Several openings are provided on the side plate 1 . The opening is circular, square or oval.

[0013] An embodiment of the present invention has been described in detail above, but the content described is only a preferred embodiment of the present invention, and cannot be considered as limiting the implementation scope of the present invention. All equivalent changes and improvements made according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com