A kind of Invar alloy for large-scale integrated circuit manufacturing equipment and preparation method thereof

A large-scale integrated circuit and invar technology, which is applied in the field of alloys and their preparation, can solve the problems that the production and use requirements of large-scale integrated circuit manufacturing equipment cannot be met, the processing and manufacturing process is complicated, and the cost of alloy elements is high, and the comprehensive performance can be maintained. , less alloying elements, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

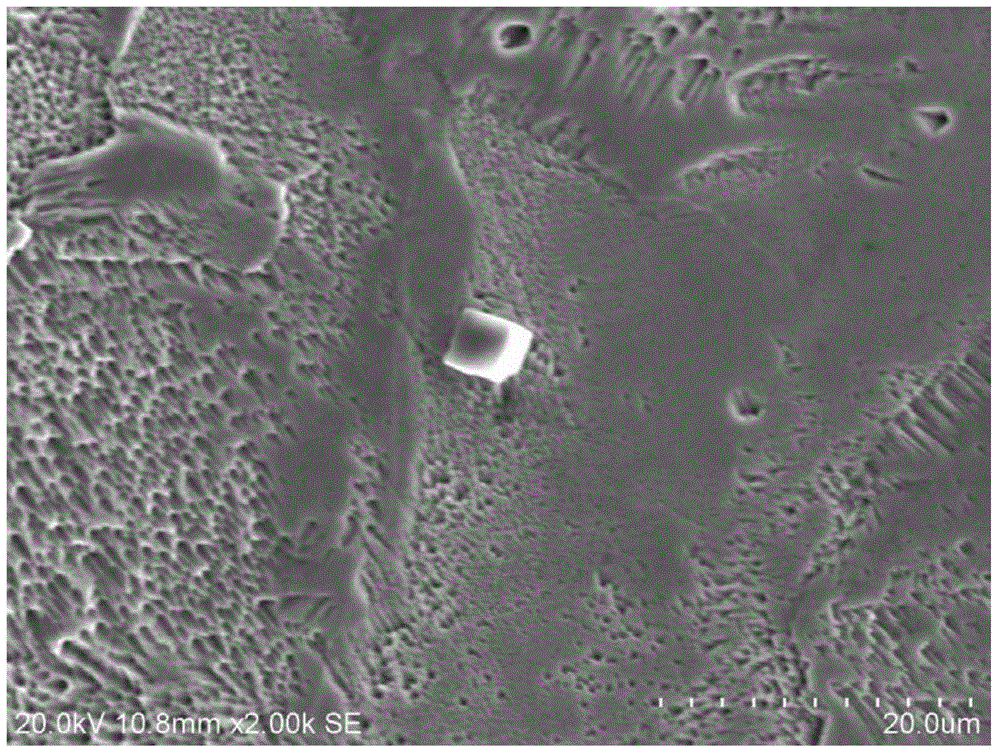

Image

Examples

specific Embodiment approach 1

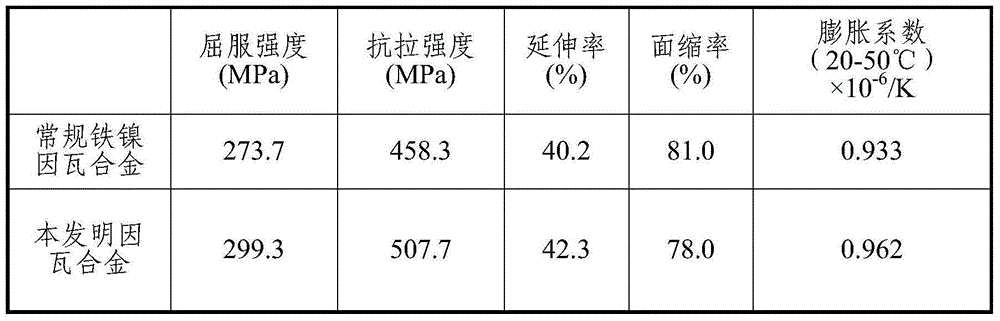

[0037] Specific embodiment 1: In this embodiment, a method for preparing Invar alloy for large-scale integrated circuit manufacturing equipment is carried out according to the following steps: 1. The raw materials are distributed by mass, and the mass of electrolytic nickel accounts for 34.0-38.0 of the total mass of raw materials. %, the quality of sponge titanium accounts for 0.01% to 0.5% of the total mass of raw materials, the balance is electrolytic iron, and the mass of C element contained in it accounts for 0.001% to 0.1% of the total mass of raw materials; 2. The temperature is 1520-1580℃ and vacuum Degree is 0.5×10 -2 ~5×10 -2 Invar alloy is smelted by vacuum arc under Pa conditions, and the holding time is 5~30min to obtain the melt; adjust the temperature to 1450~1520℃, and then cast into ingot; 3. Heat the ingot to 1000~1200℃, Pressure processing to obtain products; 4. Heat treatment of the obtained products, heat to 800~900℃ for 0.5~3h, quickly cool to room temperat...

specific Embodiment approach 2

[0038] Embodiment 2: The only difference between this embodiment and the specific embodiment is that in step 1, the quality of electrolytic nickel accounts for 35.5 to 36.5% of the total mass of raw materials.

specific Embodiment approach 3

[0039] Specific embodiment three: this embodiment is different from specific embodiment one or two in that in step one, the mass of sponge titanium accounts for 0.05% of the total mass of raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com