Invar alloy for large scale integrated circuit manufacturing equipment and preparation method of invar alloy

A technology of large-scale integrated circuits and Invar alloys, which is applied in the field of alloys and their preparation, can solve the problems of not being able to meet the production and use requirements of large-scale integrated circuit manufacturing equipment, complex processing and manufacturing processes, and high cost of alloying elements, so as to maintain comprehensive performance , less alloying elements, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

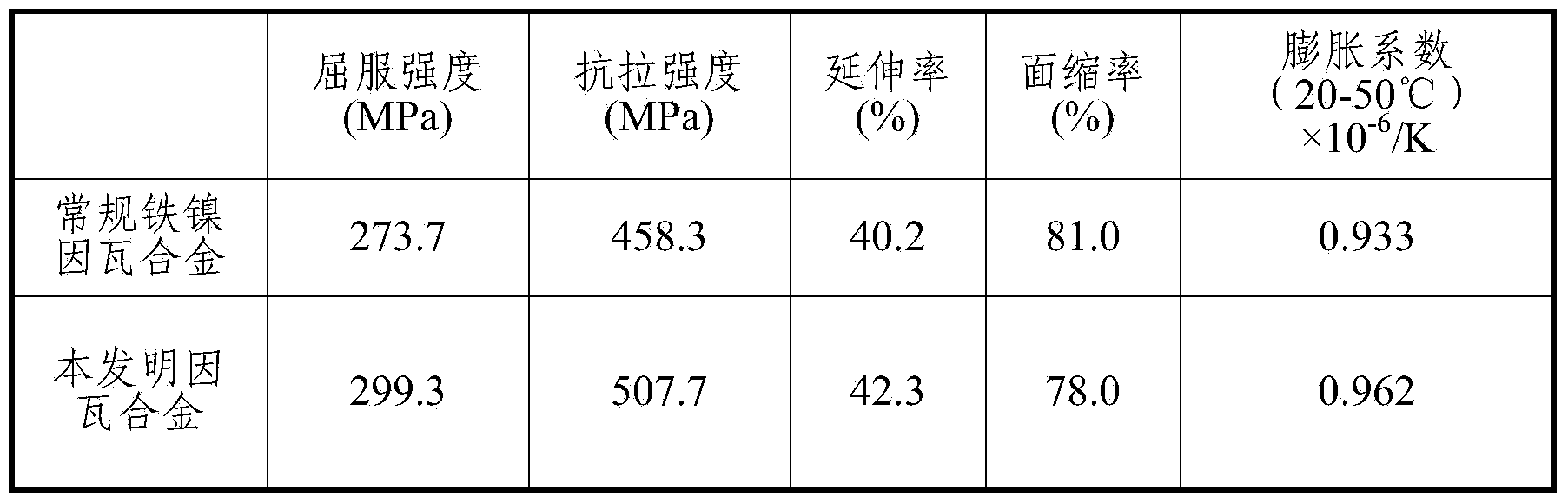

[0037] Embodiment 1: In this embodiment, a method for preparing Invar alloy for large-scale integrated circuit manufacturing equipment is carried out according to the following steps: 1. Raw materials are distributed by mass, and the quality of electrolytic nickel accounts for 34.0 to 38.0% of the total mass of raw materials. %, the mass of titanium sponge accounts for 0.01% to 0.5% of the total mass of raw materials, and the balance is electrolytic iron, in which the mass of C element contained in it accounts for 0.001% to 0.1% of the total mass of raw materials; The degree is 0.5×10 -2 ~5×10 -2 Vacuum arc melting Invar alloy under the condition of Pa, the holding time is 5-30min, and the melt is obtained; the temperature is adjusted to 1450-1520°C, and then cast into an ingot; 3. The ingot is heated to 1000-1200°C, and it is processed Pressure processing to obtain products; 4. Heat treatment of the obtained products, heating to 800-900°C for 0.5-3 hours, cooling to room tem...

specific Embodiment approach 2

[0038] Embodiment 2: The only difference between this embodiment and the specific embodiment is that the mass of electrolytic nickel in step 1 accounts for 35.5-36.5% of the total mass of raw materials.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the mass of titanium sponge accounts for 0.05% of the total mass of raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com