Novel heat-insulating coldness-preserving material

A heat insulation and cold preservation technology, applied in the direction of heat insulation protection of pipelines, heat preservation, pipeline protection, etc., can solve the problems of low thermal conductivity, no reflection function, difficult construction, etc., and achieve the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

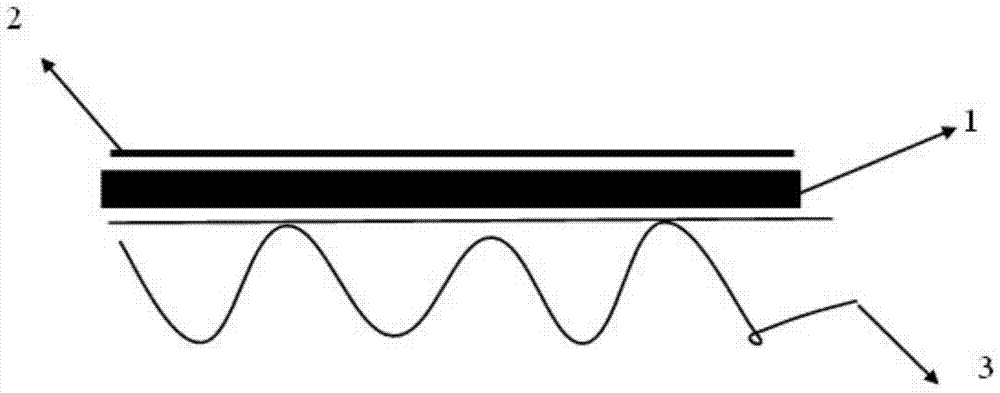

[0016] attached figure 1 It is a new type of heat insulation and cold preservation material described in the present invention, which uses flame retardant modified PVC CaCO 3 1 is the middle base layer, the flame retardant modified PVC CaCO 3 The first composite aluminum foil heat-insulating reflective layer 2 is attached on the upper surface of 1; the flame-retardant modified PVC CaCO 3 The lower surface of 1 is attached with 10-100 mm of highly soft and highly elastic sound-absorbing foam 3; the flame-retardant modified PVC CaCO 3 1 has a thickness of 3-10 mm, and has excellent properties such as high elasticity, low temperature resistance, and anti-aging; the first composite aluminum foil heat-insulating reflective layer 2 is made of modified polyethylene film, high-mirror aluminum foil, and PET polyester film. The thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com