Mounting structure of a lamp assembly

A technology for installation structures and lamps, which is applied in cooling/heating devices of lighting devices, lighting devices, lighting auxiliary devices, etc. It can solve the problems of environmental temperature installation breakage, overall weight increase, and unsightly appearance, and achieve a high degree of overall combination stability , simplified assembly, beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

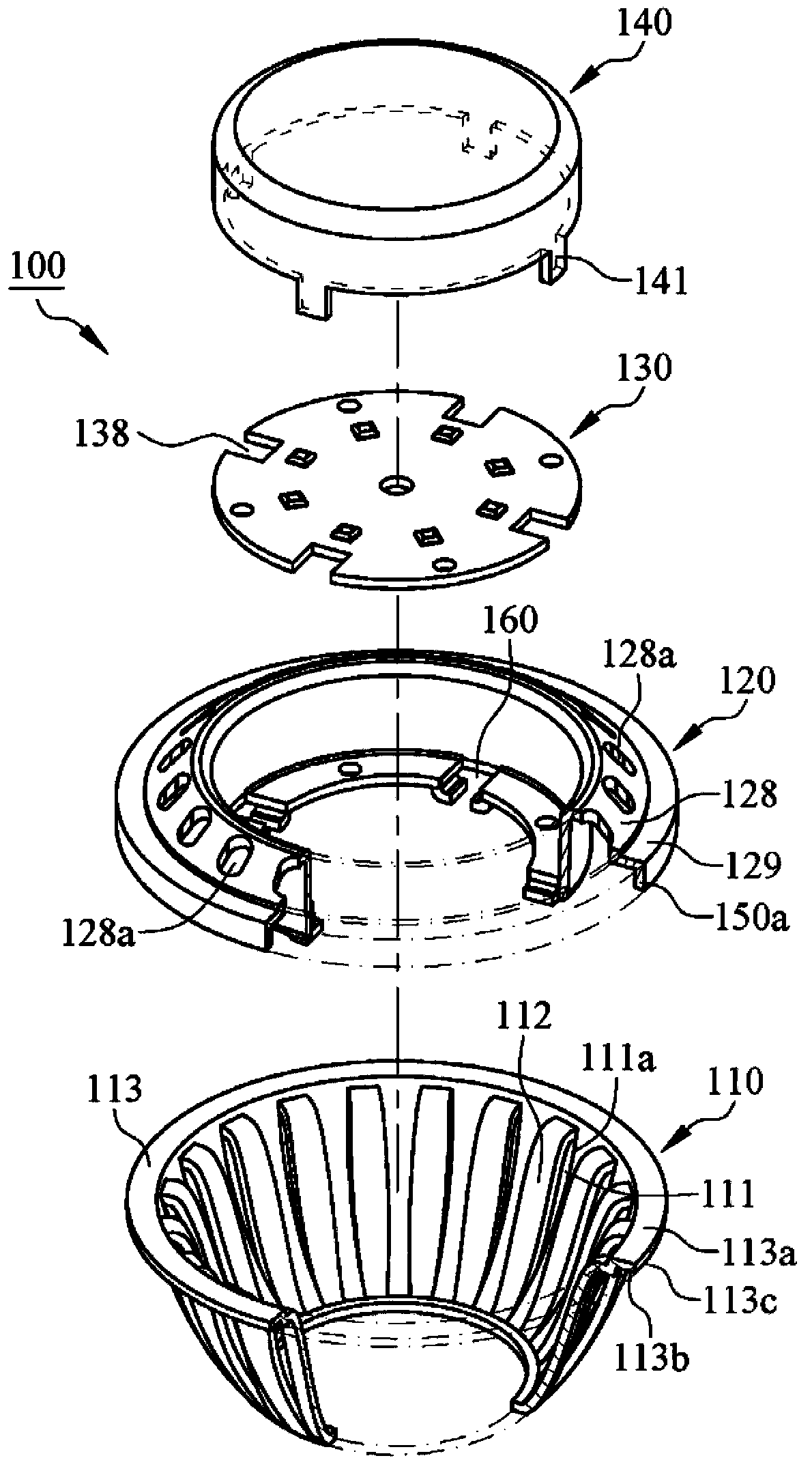

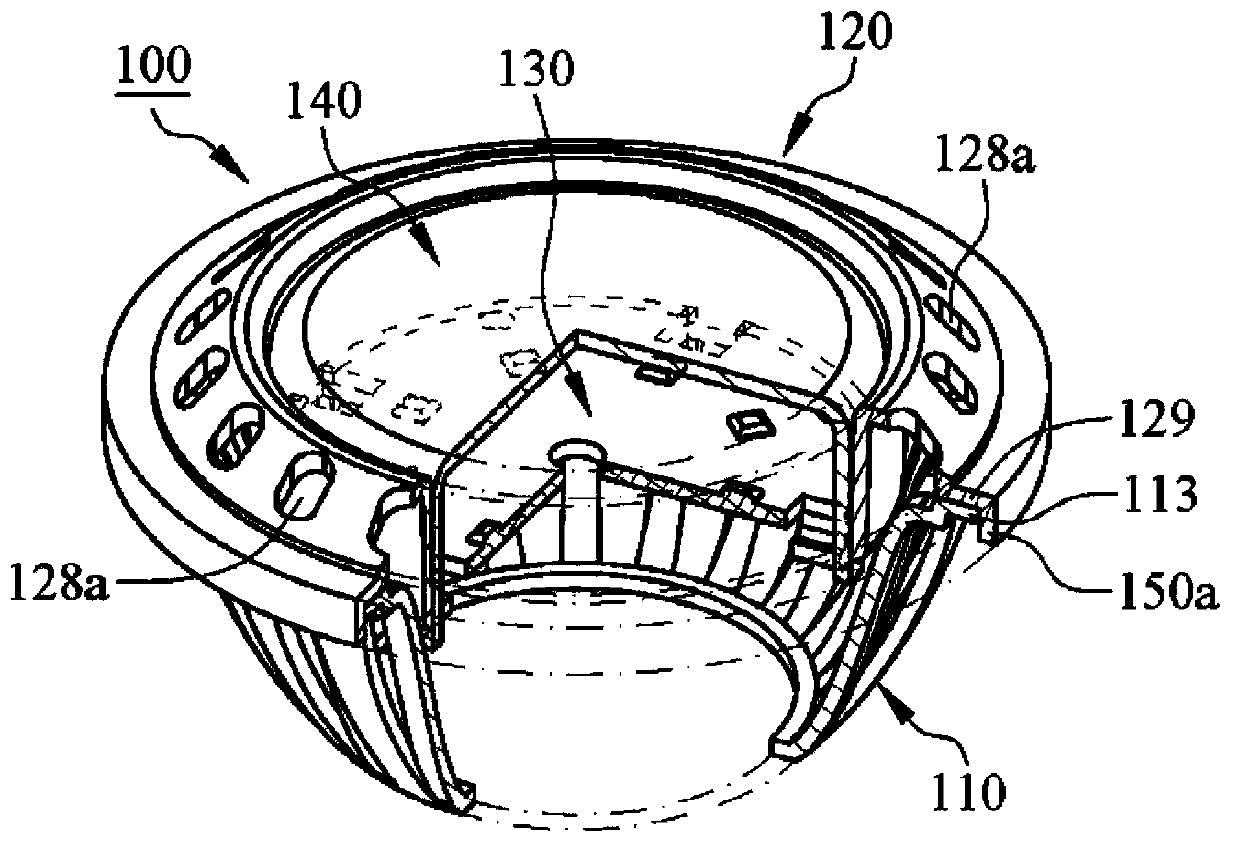

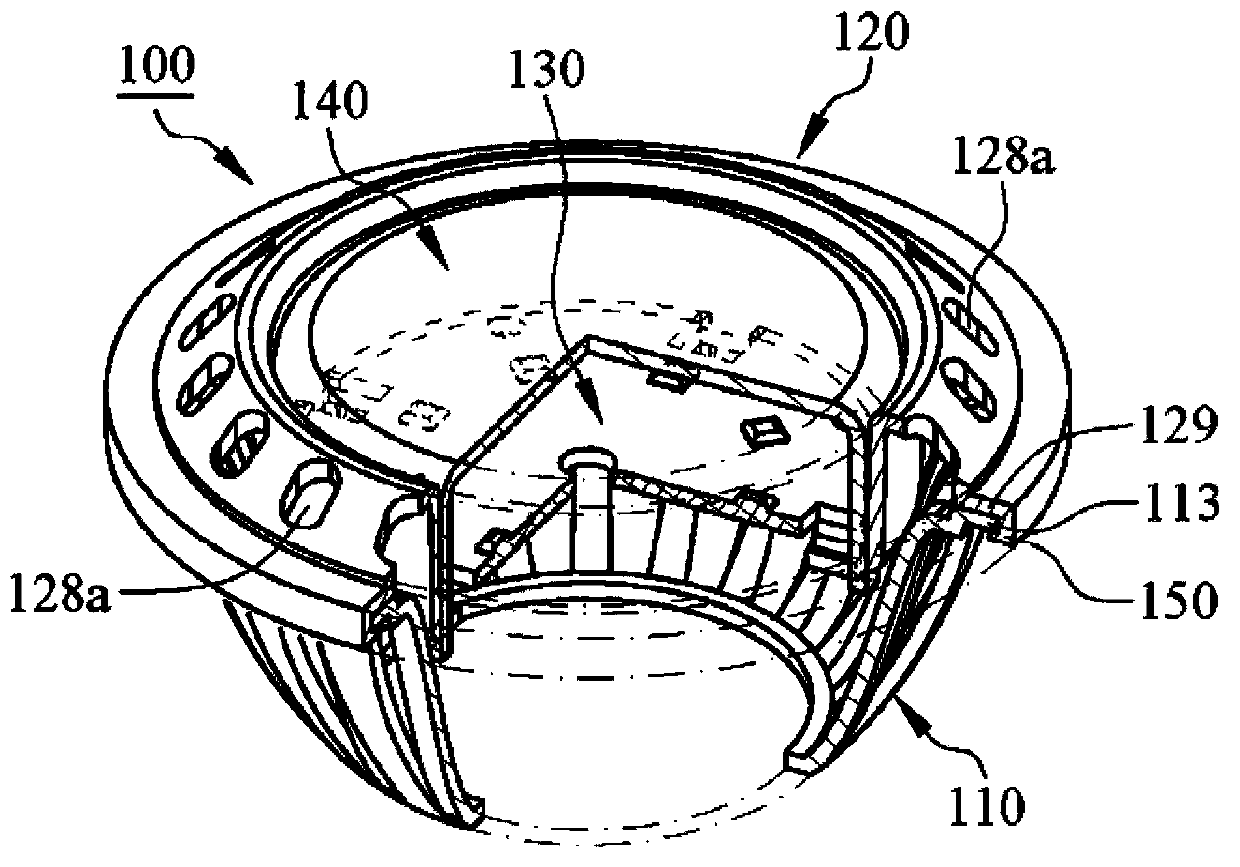

[0068] see figure 1 and figure 2 , which is the first embodiment of the present invention, a lamp installation structure 100, the lamp includes a light emitting module 130 arranged on the installation structure 100 and a lampshade 140 for emitting light from the light emitting module 130, the light emitting module 130 There are a plurality of openings 138, the lampshade 140 has a plurality of plug-in pieces 141, the mounting structure 100 at least includes a first mounting seat 110 and a second mounting seat 120 in which the first mounting seat is combined with each other, the light emitting module 130 locks Combined with the second mounting base 120, the first mounting base 110 has a plurality of heat dissipation openings 111, a plurality of heat dissipation ribs 112 and a stop portion 113, each of the heat dissipation openings 111 has a side wall 111a, and each of the heat dissipation protrusions Ribs 112 are formed on each of the side walls 111a to increase heat dissipat...

no. 6 example

[0080] see Figure 13 and Figure 14 , which is the sixth embodiment of the present invention, the difference between this embodiment and the fourth embodiment is that the first positioning plate 124 of each of the limiting members 123 has a first surface 124a, a second surface 124b and a through hole 124c, each of the through holes 124c communicates with each of the first surface 124a and each of the second surfaces 124b, each of the through holes 124c has a hole wall 124d, and each of the second positioning plates 125 of the position limiting member 123 is formed by stamping Protrudes from each of the first surfaces 124a in a manner, and each of the second positioning plates 125 is connected to each of the hole walls 124d.

[0081] see Figure 14 , Figure 15 and Figure 16 , in this embodiment, the combination of the second mounting base 120 and the base plate 131 is as follows: each of the positioning holes 134 of the base plate 131 is aligned with each of the position...

no. 8 example

[0085] see Figure 21 and Figure 22 , is the eighth embodiment of the present invention, a lamp installation structure 100, which includes a first installation base 110 and a second installation base 120 combined with the first installation base 110, wherein the light emitting module 130 and The lampshade 140 is combined with the first mounting base 110, the first mounting base 110 has a stop portion 113, the second mounting base 120 has a limiting portion 129 and a clamping portion connected to the limiting portion 129 150 , the clamping portion 150 is deformable under force, and the stop portion 113 of the first installation seat 110 is limited between the clamping portion 150 and the limiting portion 129 to form a hidden state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com