Angle sensor

An angle sensor and housing technology, applied in the direction of instruments, using electric/magnetic devices to transmit sensing components, measuring devices, etc., can solve problems such as prone to errors, hidden dangers of driving safety, and low product reliability, and meet the needs of gears Signal output requirements, improved reliability and durability, and the effect of overcoming mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

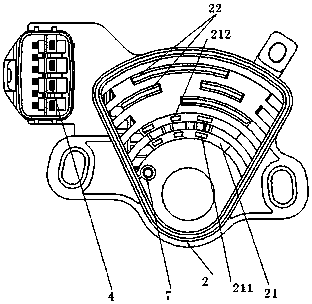

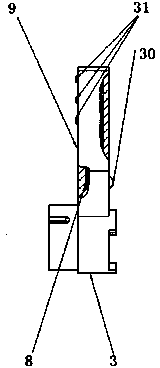

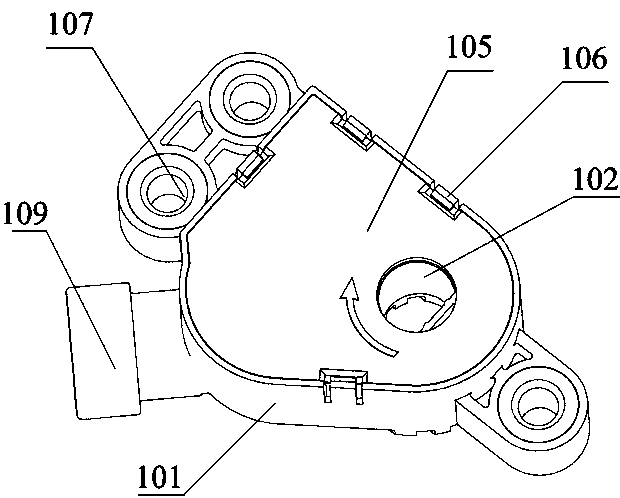

[0018] An angle sensor of this embodiment, such as Figure 3-Figure 4 As shown, a housing 101 is included. One side of the housing 101 has an open space, and a rotor 102 and a Hall chip 103 are arranged in the open space. A magnet 104 is arranged on the rotor 102 , and the magnet 104 is biased relative to the Hall chip 103 . The rotating shaft of the gearbox PRND handle matches the rotor 102 and drives the rotor 102 to rotate. It also includes an upper cover 105 corresponding to the housing 101 , and the upper cover 105 closes the open space through a buckle structure 106 . A plurality of fixed copper sleeves 107 are provided on the outer wall of the housing 101 . The Hall chip 103 is installed on the circuit board 108 , and the circuit board 108 protrudes out of the housing 101 through the plug 109 .

[0019] When applying this embodiment, the rotating shaft of the PRND handle of the gearbox drives the rotor 102 to rotate, and then drives the magnet 104 to rotate, and the H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com