Gear compressor

A gear type and compressor technology, applied in compressors, rotary piston machines, refrigerators, etc., can solve the problems of difficulty in installing and stabilizing devices, increase in size and weight, and leakage of compressed gas, so as to achieve no toxicity and reduce vibration As well as noise and the effect of preventing mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

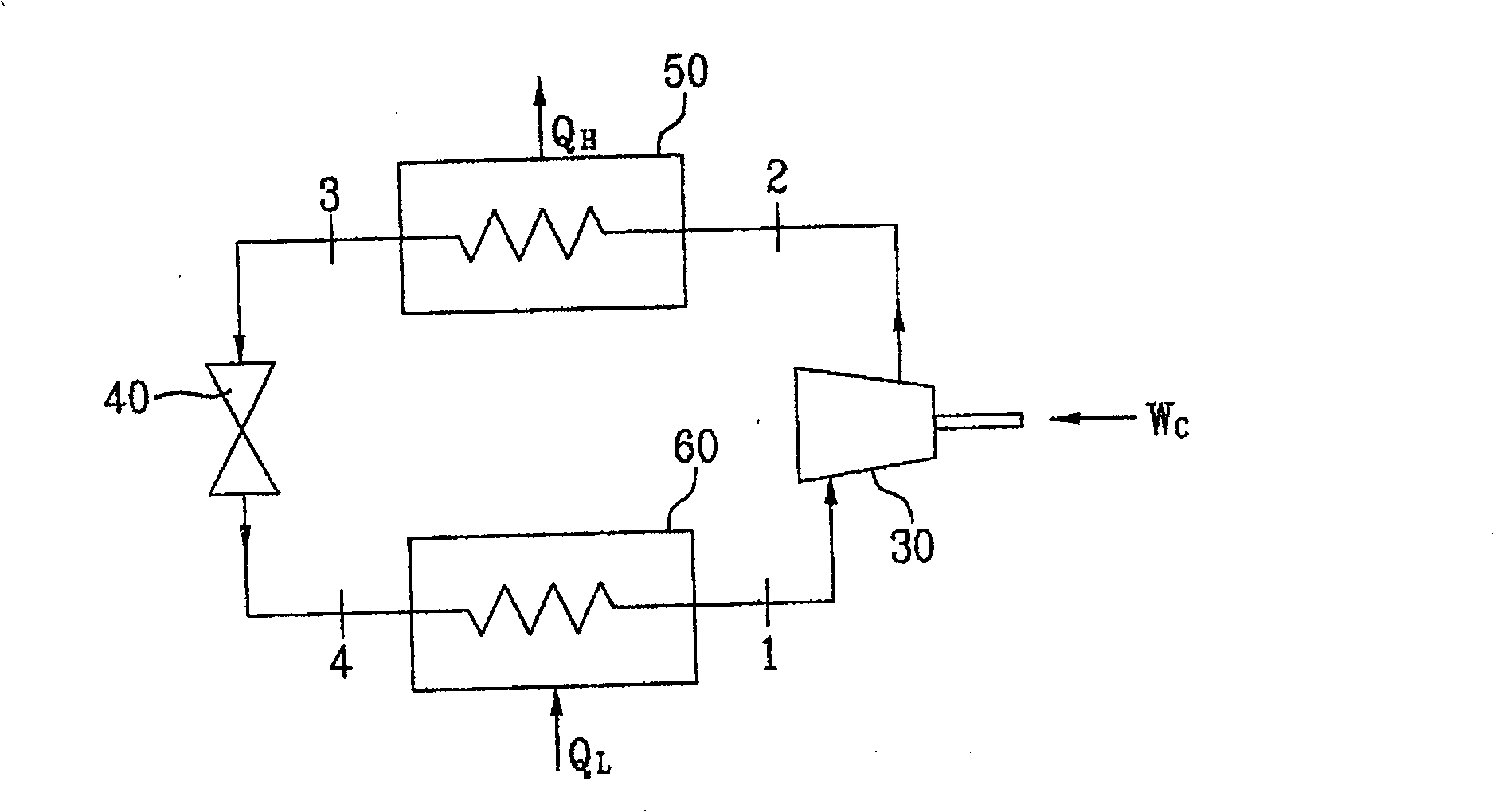

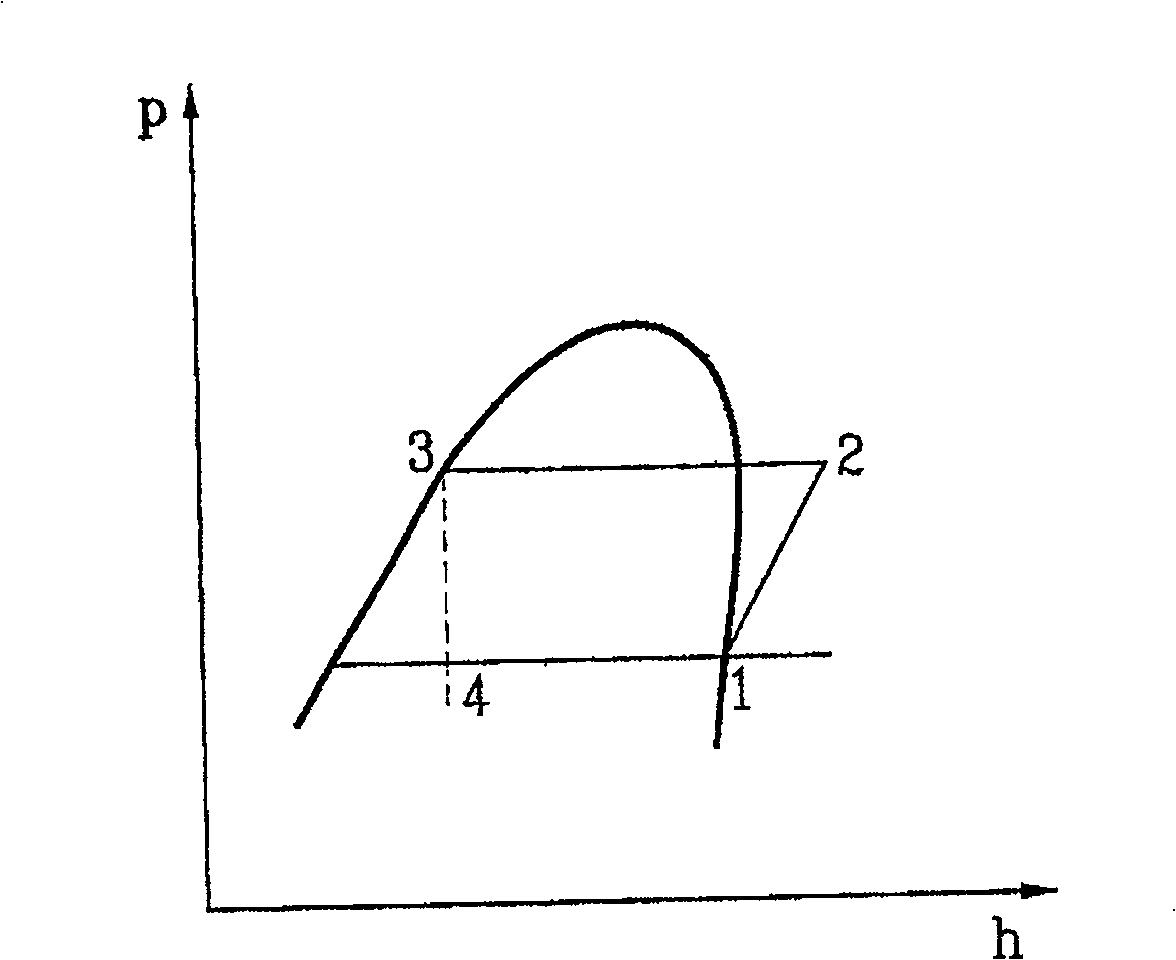

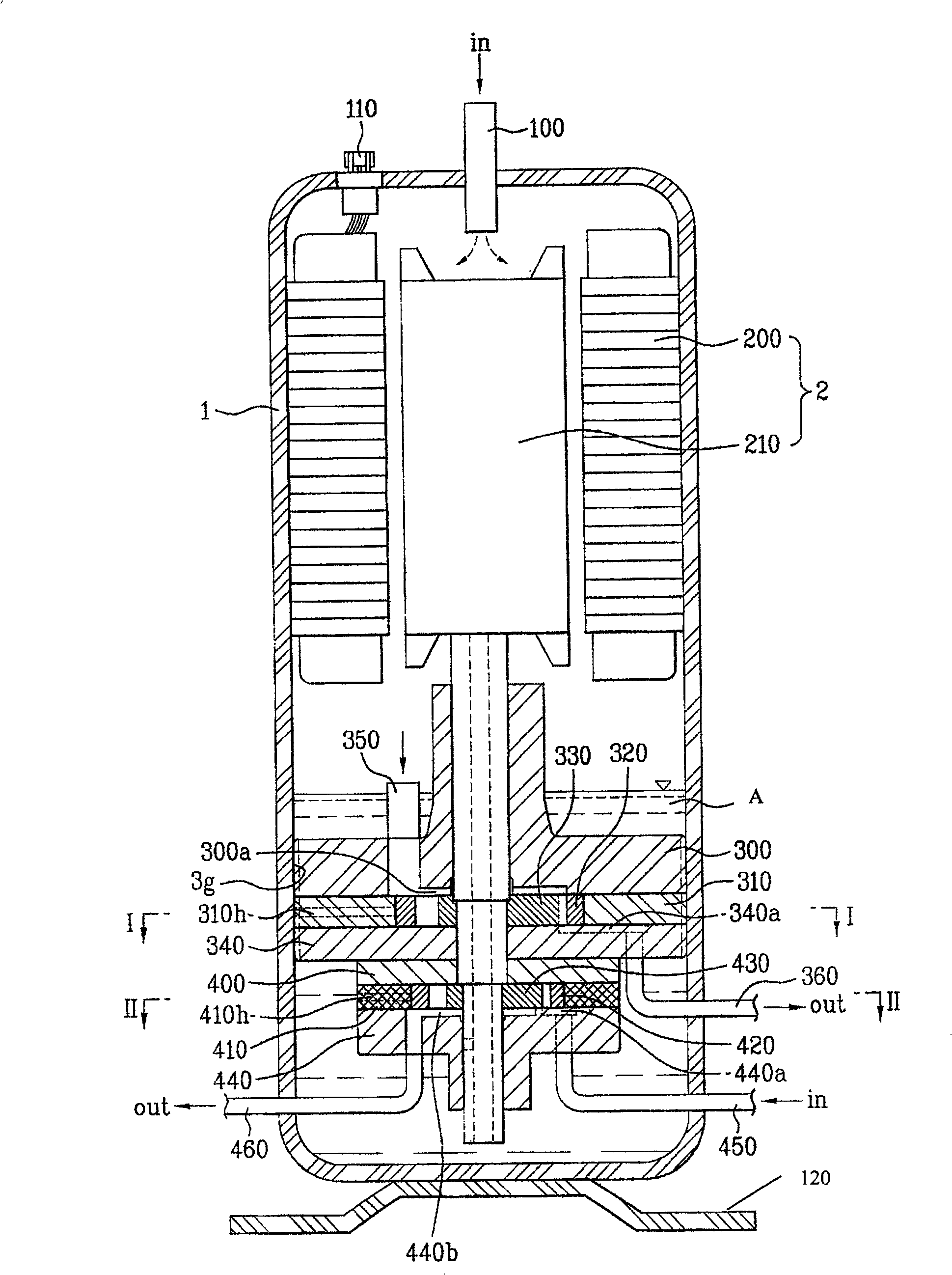

[0046] Such as image 3 , 4a , 4b, 5, 6, and 7, the gear compressor of the present invention includes a shell 1 with a designated space inside; a motor 2 arranged inside the shell 1; the driving force of the motor 2 is compressed and flows from the evaporator 6 The gear-type compression part 3 of the refrigerant; the gear-type expansion part 4 that expands the refrigerant discharged from the compression part 3 and re-absorbed through the condenser 5.

[0047] The motor 2 is composed of a stator 200 installed on the inner wall of the housing 1 ;

[0048] The gear type compression part 3 includes a main bearing 300 fixed on the lower side of the motor 2 in the housing 1; an annular compression cylinder 310 connected to the bottom of the main bearing 300 and having an oil groove 320g formed on the outer peripheral surface; located in the inner sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com