Method for testing engine vibration noise under whole-automobile condition

A testing method, vibration and noise technology, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of time-consuming, laborious, large amount, and difficult data acquisition, and achieve the effect of saving production costs and being easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

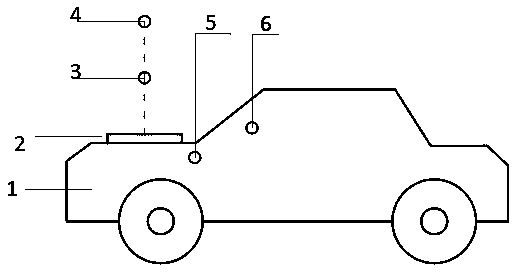

[0033] Further illustrate this method below in conjunction with accompanying drawing:

[0034] 1 The test equipment to be used

[0035] (1) Vibration and noise test system and sensors.

[0036] (2) Sound intensity measurement system or acoustic holographic test system.

[0037] (3) The microphone used for the test shall comply with the requirements for Class 1 instruments specified in GB / T3785.

[0038] (4) The measuring device used for the test is to cover at least the frequency range from 20Hz to 10000Hz.

[0039] (5) Before and after the test, the test instrument should be calibrated according to the regulations, the two calibration values should not exceed 1dB, and the accuracy of the calibrator should be better than or equal to ±0.5dB.

[0040] (6) The accuracy of the test instruments for vehicle speed and engine speed should be guaranteed to be less than 3%.

[0041] 2 Test conditions

[0042] 2.1 Site conditions: vehicle anechoic chamber

[0043] 2.2 Excep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com