Bearing simulation test bed for vertical shaft type pumping and storing hydropower unit

A test bench, vertical shaft technology, applied in the field of devices for simulation research on the shaft system/bearing operation mechanism of vertical shaft pumped storage hydraulic units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

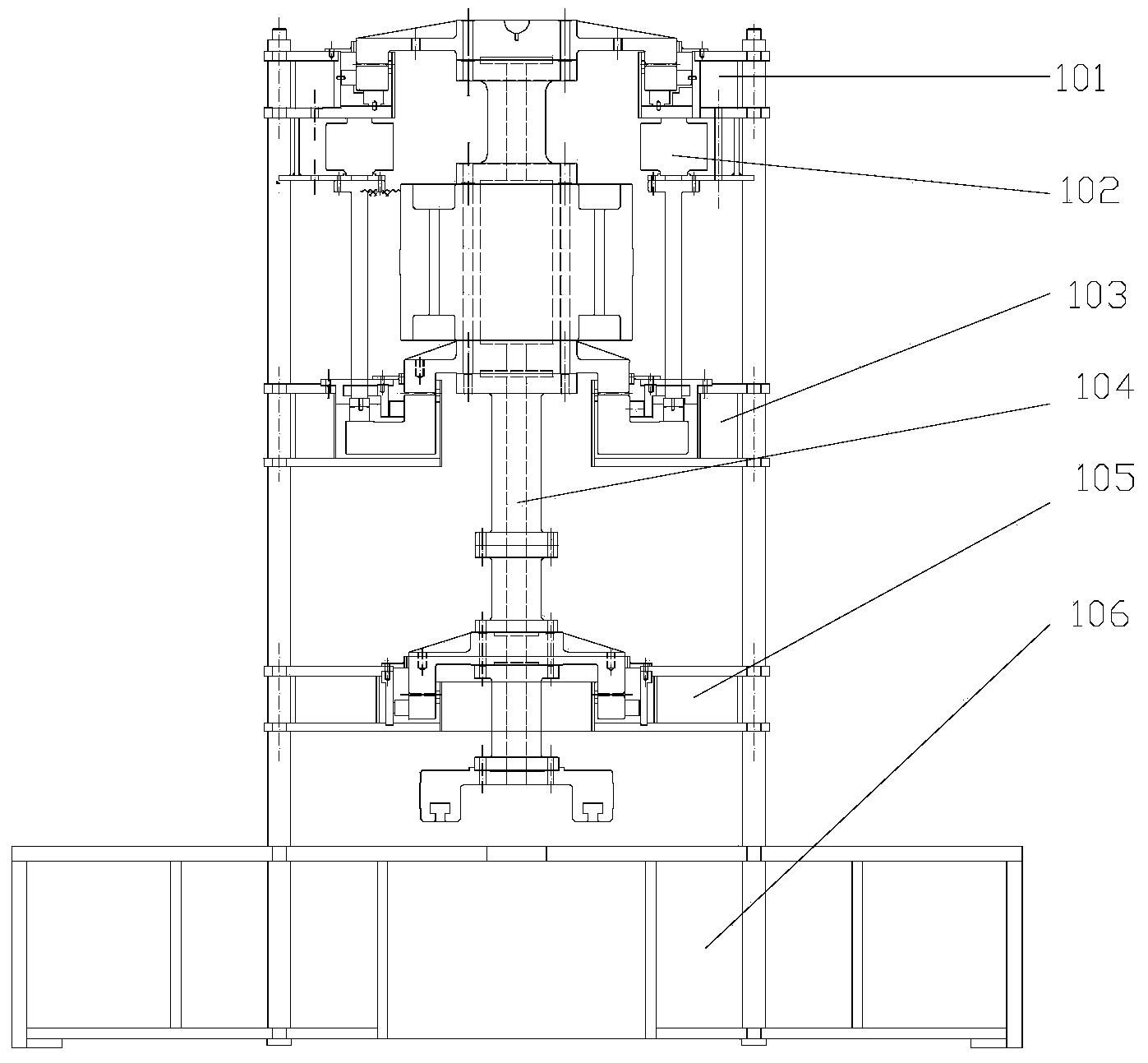

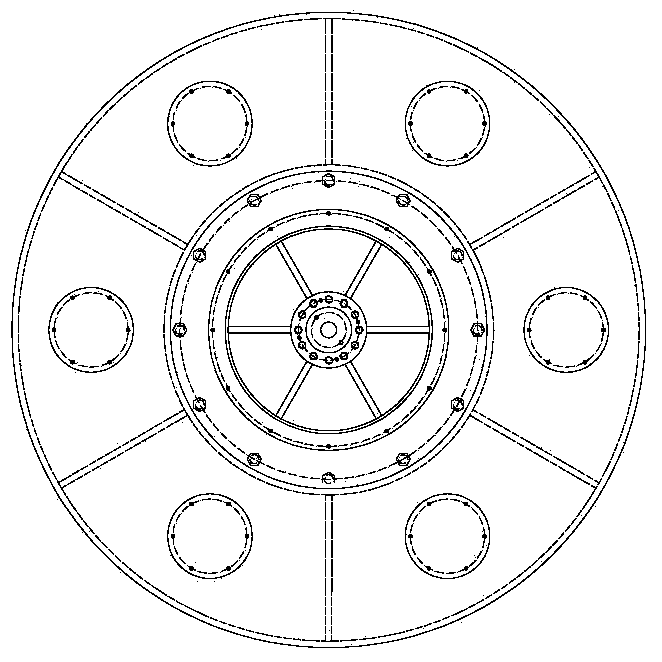

[0065] see Figure 1a , Figure 1b and Figure 2a , Figure 2b , the embodiment of the bearing simulation test bench of the vertical shaft type pumped storage hydraulic unit of the present invention comprises a rotating shaft system 1, a test bench upper frame 101, a test bench lower frame 103, a test bench water guiding frame 105, and a test bench stabilization box Body 106 and test bench loading device 102, wherein the upper frame of the test bench, the lower frame of the test bench, the water guide frame of the test bench and the stable box of the test bench pass through multiple Connect with long through bolts.

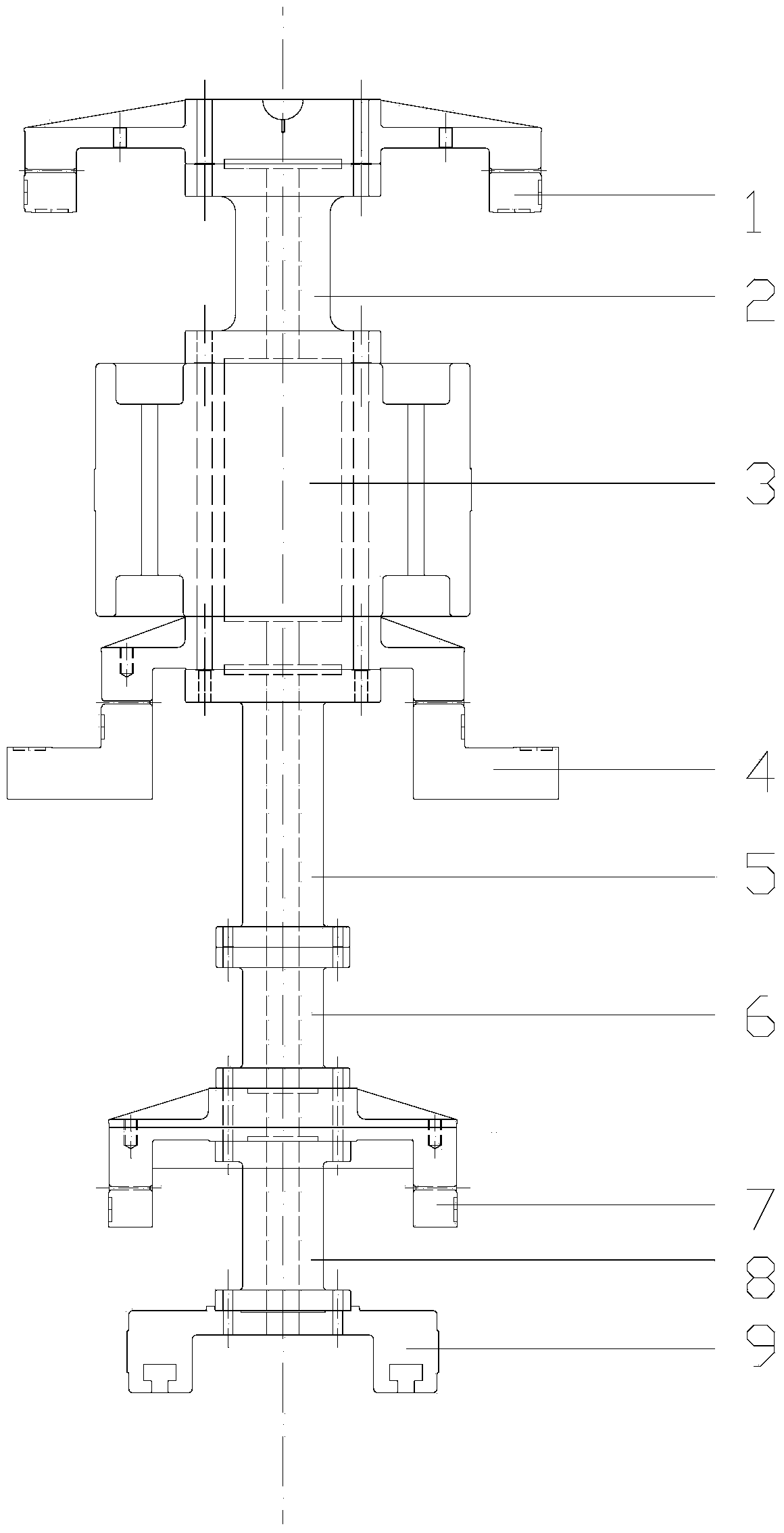

[0066] The rotating shaft system from top to bottom includes upper guide and thrust bearing 1, thrust connecting shaft 2, generator / motor rotor 3, lower guide and loading bearing 4, lower end shaft 5, connecting shaft 6, water guide bearing 7, water guide There are nine parts of the shaft 8 and the runner 9, and the two adjacent parts are connected by bolts;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com