Sample making mold with controllable undulation and undulation structure surface and its application method

A technology of structural surface and undulation, which is applied in the direction of manufacturing tools, test sample preparation, ceramic molding machines, etc., can solve the problems of difficult sampling on site, few test samples, high test cost, etc., achieve convenient sample preparation and save materials , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

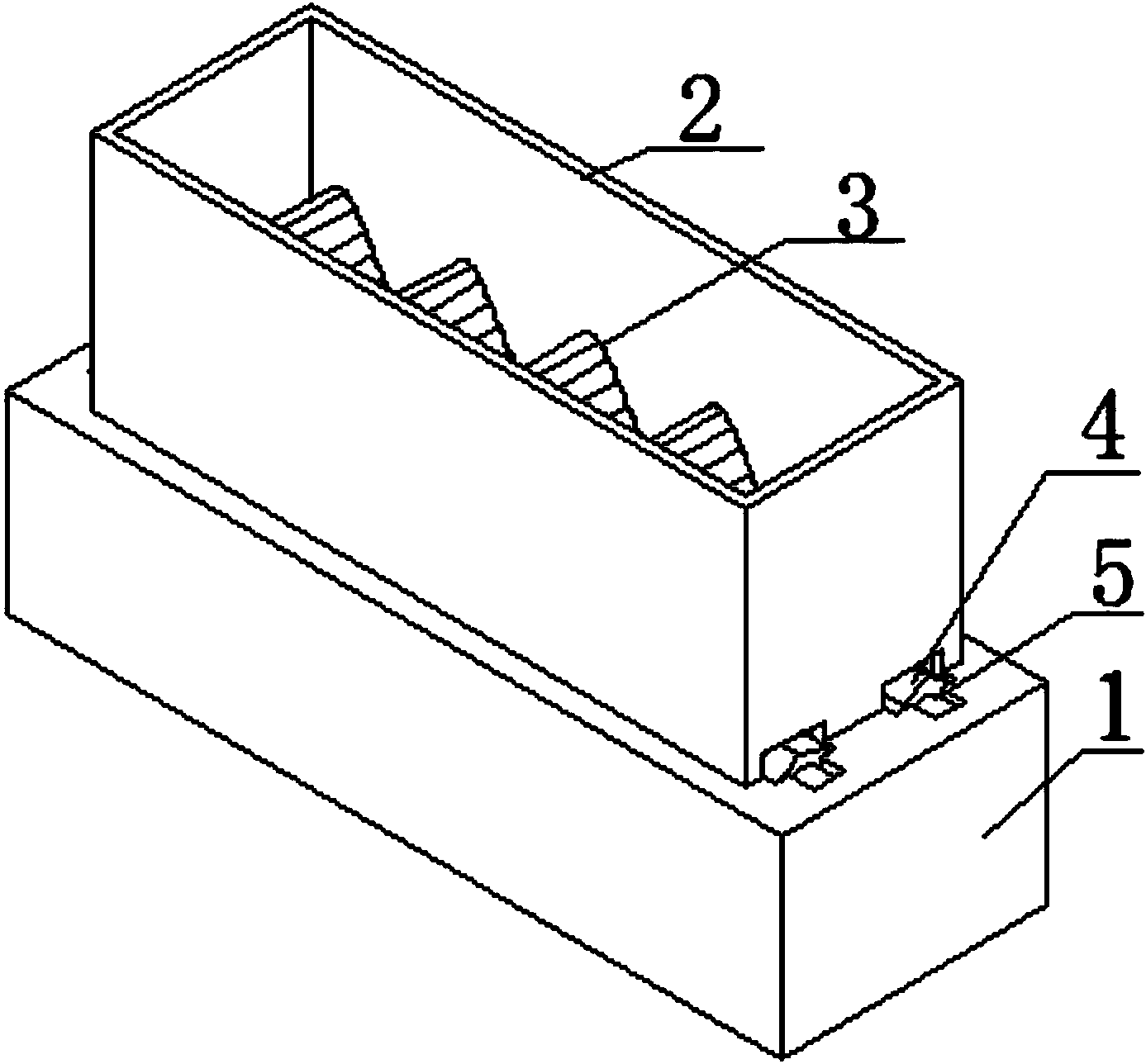

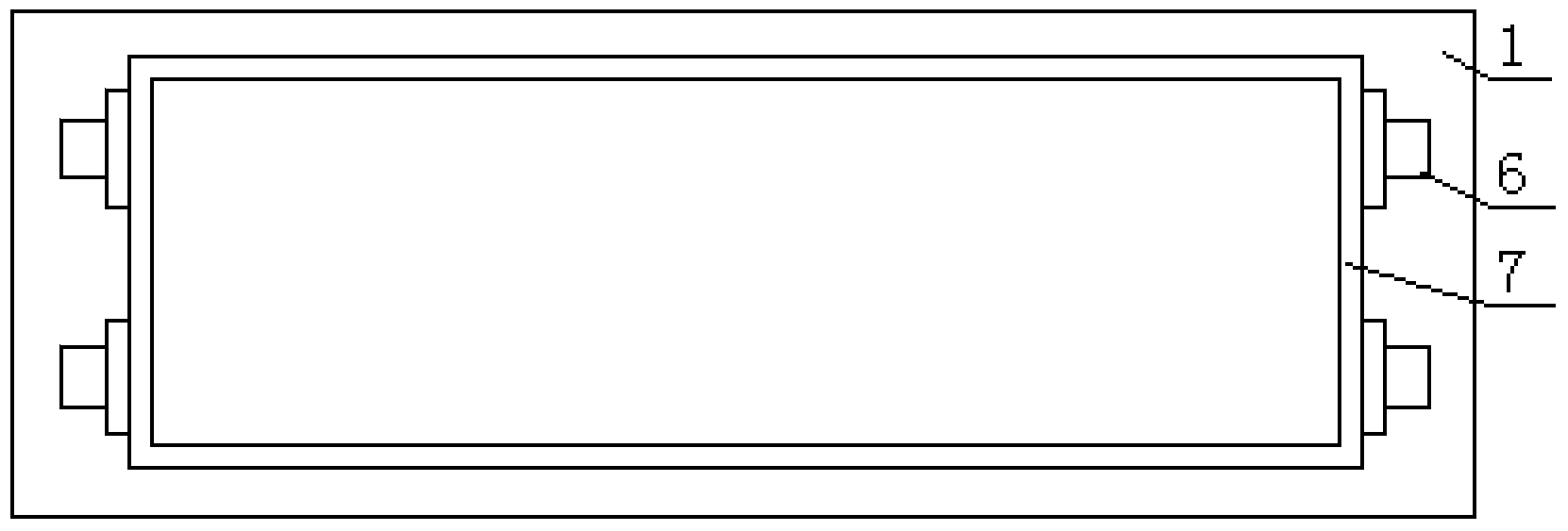

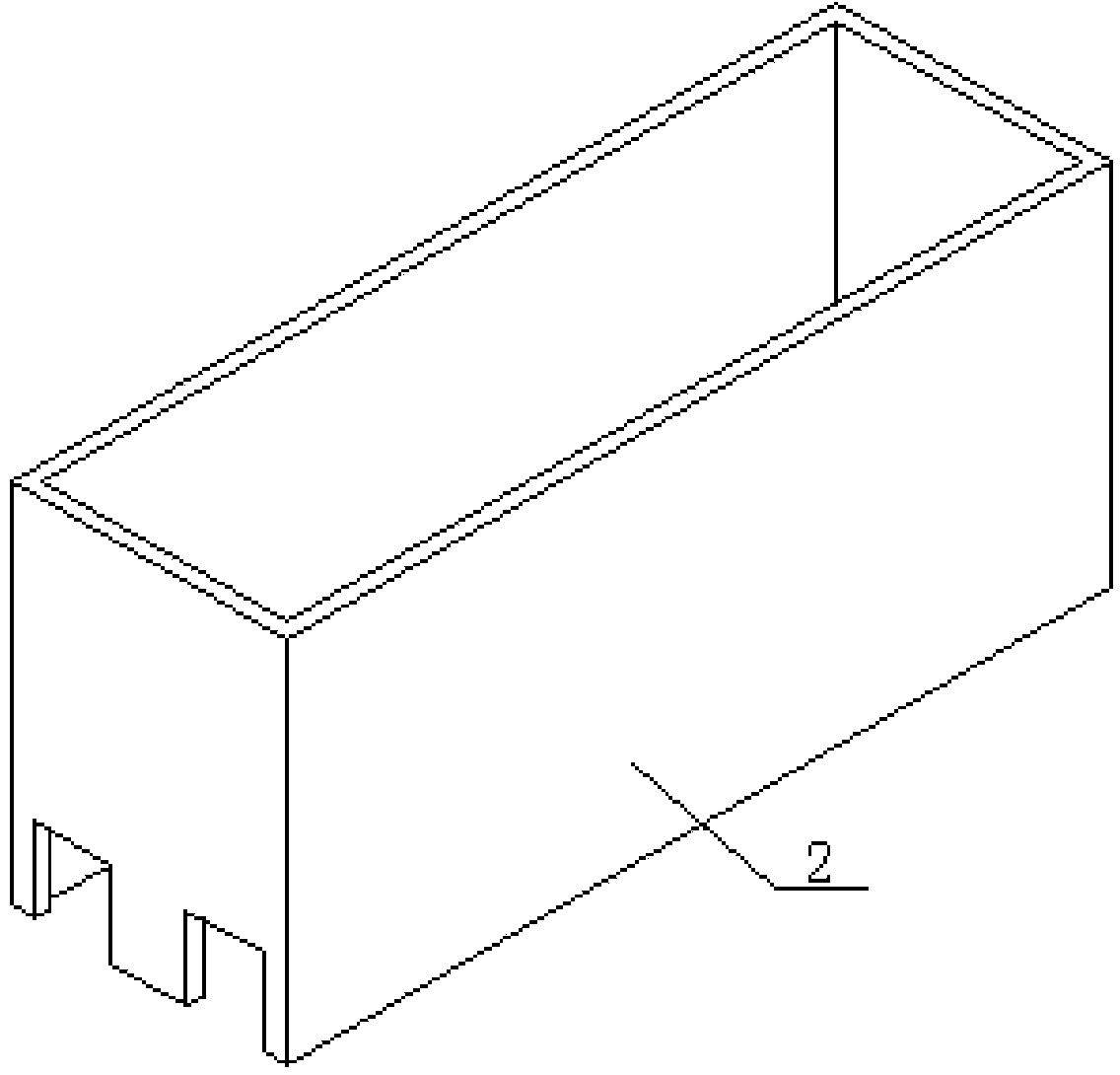

[0033] Embodiment 1: A sample production mold with controllable undulations provided by the present invention, its overall structure is as follows figure 1As shown, adopting the idea of modular design, a groove-shaped positioning base 1, an arc-shaped movable plate 3 and a mold outer frame 2 are designed. The groove-shaped positioning base 1 is a rectangular groove body, see figure 2 , the upper frame of the tank body is provided with a circle of small steps 7, and two T-shaped grooves 6 are arranged in the wide sides of both sides of the tank body, and the arc movable plate 3 is positioned in the groove shape by the screw rod 5 and the nut 4. In the positioning base 1, the screw rod 5 and the nuts 4 at both ends fall on 2 T-shaped grooves 6 provided with the grooved positioning base; The perimeters of the small steps are equal, and notches are arranged in the broad sides of the mold frame 2, see image 3 , the outer frame of the mold is covered outside the arc-shaped mova...

Embodiment 2

[0036] Embodiment 2: use the method for the mold making test model of the embodiment of the present invention 1, operate as follows:

[0037] (a) before using the mold of the present invention to make the test model, first determine the structural surface relief angle and size for the test, and clearly draw the outline of the structural surface relief angle and size on a plane; put two screw rods 5. A nut 4 is fixed at one end, and the laminations 8 are tightly placed on the two screw rods one by one. After the two screws are fitted, adjust the position of each lamination 8 sequentially according to the undulating contour of the structural surface in the drawing, and after obtaining the required undulating angle and shape of the structural surface, fix the other ends of the two screw rods tightly with nuts, so that Prevent the displacement of the laminations from slipping and affect the production of the sample; thus the arc-shaped movable plate 3 is formed.

[0038] (b) Fix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com