Device for testing intensity of installation support of vehicle-mounted gas cylinder

A technology for mounting brackets and vehicle-mounted gas cylinders, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of cumbersome testing process, danger, poor testing accuracy, etc., save manpower and time, eliminate risk factors, The effect of simplifying the testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

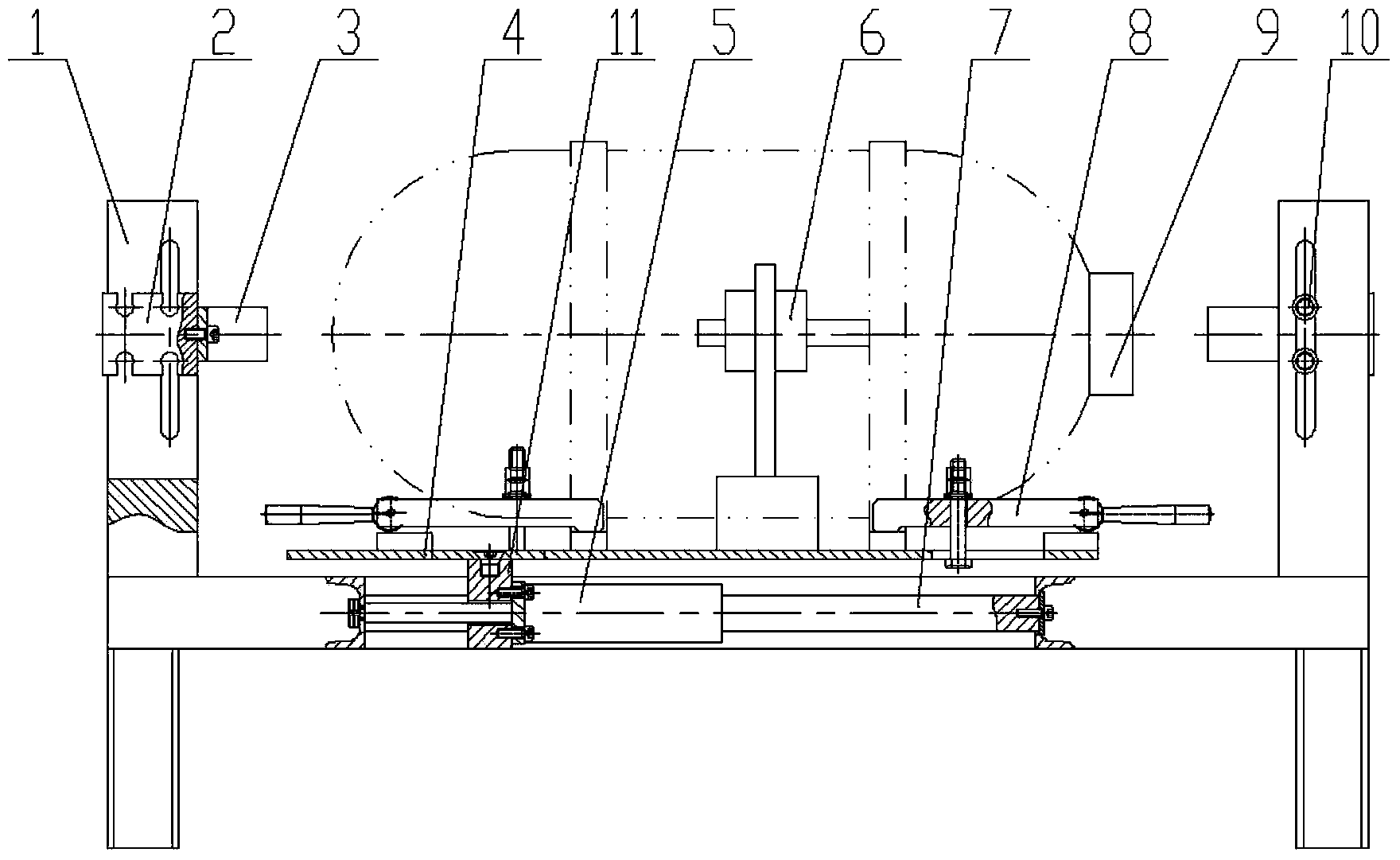

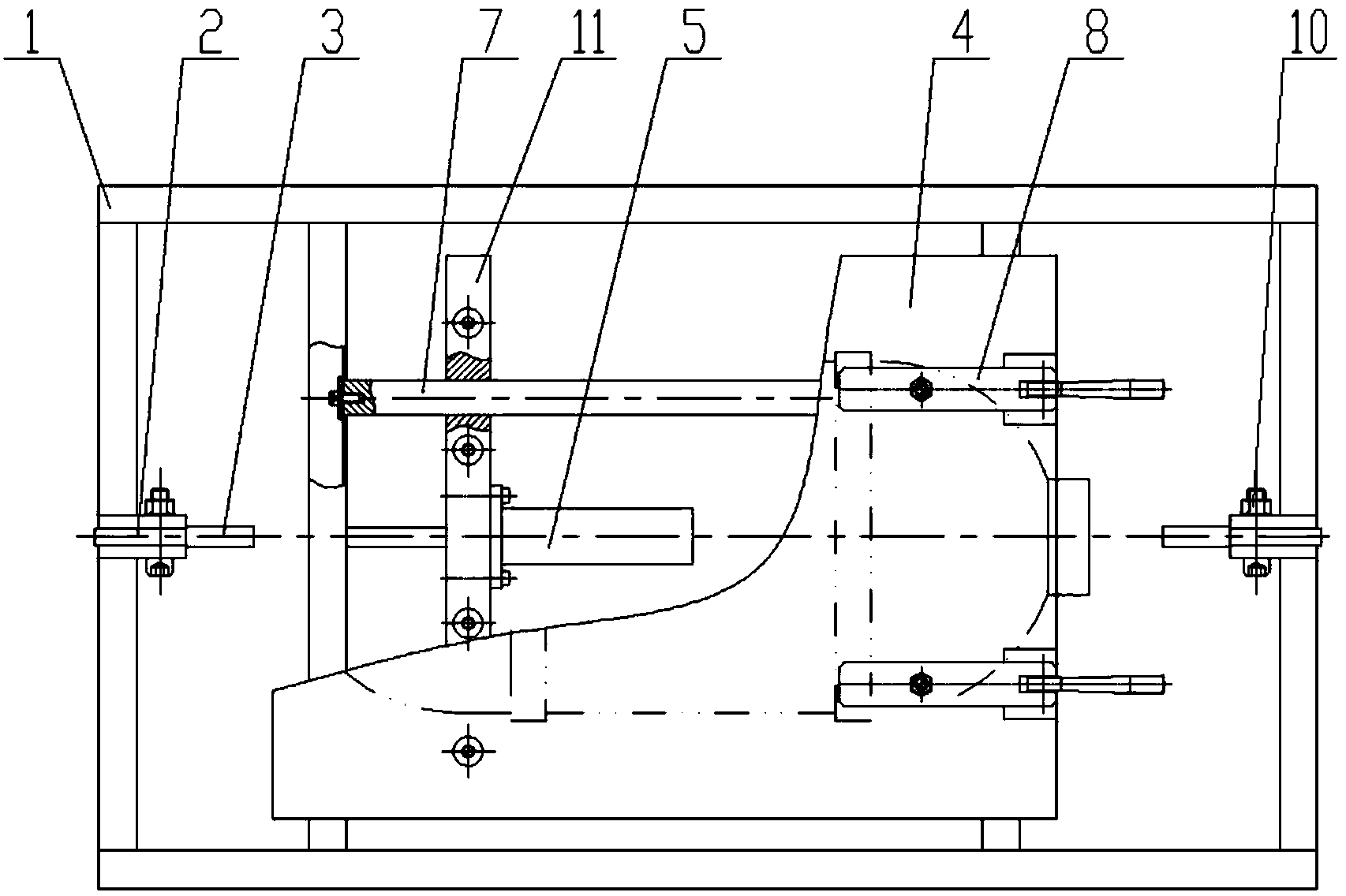

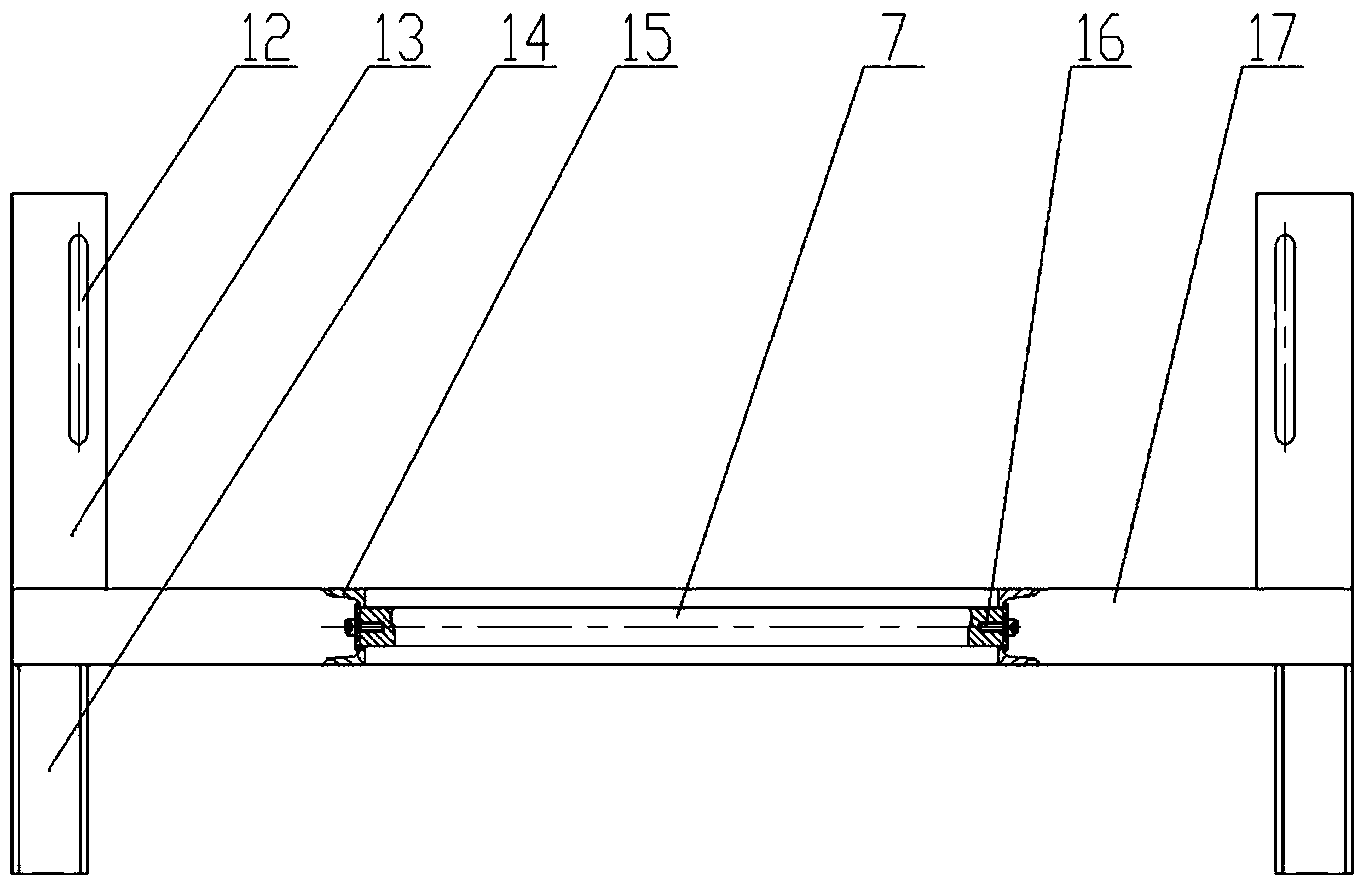

[0010] The present invention will be described in further detail below. see Figure 1 to Figure 4 , a vehicle-mounted gas cylinder mounting bracket strength testing device is characterized in that: it consists of an electrical control box, a hydraulic station, a frame 1, a position adjustment block 2, two force sensors 3, a mobile workbench and a displacement sensor unit 6; the frame 1 is composed of two columns 13, a horizontal rectangular frame 17 welded by channel steel, two beams 15, two guide rails 7 and four legs 14; the cross-section of the two columns 13 is rectangular, and the lower ends of the two columns 13 are vertical Welded on the center position of the upper surface of the two short sides of the horizontal rectangular frame 17, the upper ends of the four supporting legs 14 are vertically welded on the four corners of the lower surface of the horizontal rectangular frame 17, and two beams 15 are welded on the two long sides of the rectangular frame 17 in parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com