Rapid detection method for surface oxide scale adhesion of hot rolling strip steel

A hot-rolled strip, surface oxidation technology, applied in the metallurgical field, can solve the problems of detection value error, test accuracy interference, high cost, etc., and achieve the effects of simple detection process, rapid determination, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Example 1

[0028] 1) Take the hot-rolled automobile beam steel strip WL510, prepare a hot-rolled strip steel sample with a length of 200mm, a width of 100mm, and a thickness of 5mm, and clean the entire sample surface with alcohol;

[0029] 2) Take the adhesive tape with adhesive function, the plastic deformation ability of the tape, that is, the elongation rate of the tape is 4%, and the adhesive force of the tape is 0.3×10 -3 MPa, the tape is 150mm long and 80mm wide, the area of the tape is calculated as S=120cm 2 , And use a micro balance with a measurement accuracy of 0.1 mg to measure the weight of the tape m 1 =7.2mg;

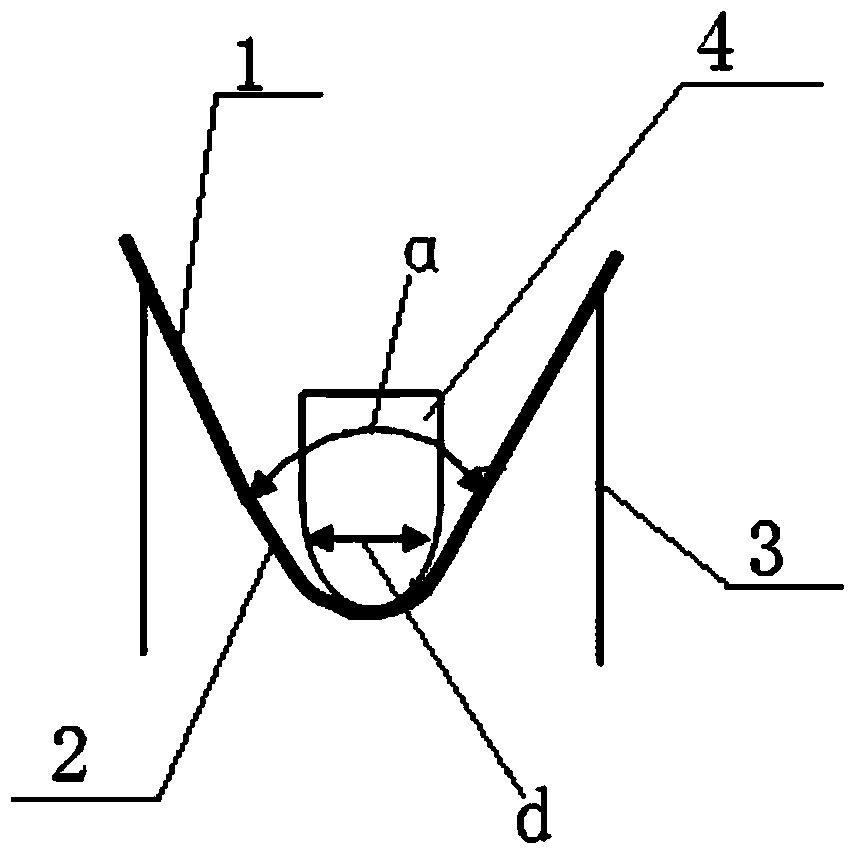

[0030] 3) Such as figure 1 As shown, the tape 2 is tightly attached to one side of the sample 1, and then the sample 1 is placed on the three-point bending tester 3 for bending test, so that the taped side of the sample 1 is the curved outer surface, and the bending angle α is 90°, the bending radius R=8mm (R=d / 2, d is the bending diameter), the redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap