Resistance type touch screen, touch point positioning method thereof and touch display device

A positioning method and resistive technology, applied in the direction of electrical digital data processing, instrumentation, data processing input/output process, etc., can solve the problems of increasing difficulty in forming strip-shaped sensing electrodes, not conforming to the development trend, and difficult manufacturing process, etc. , to achieve the effect of reducing the number, reducing the cost, and simplifying the amount of computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

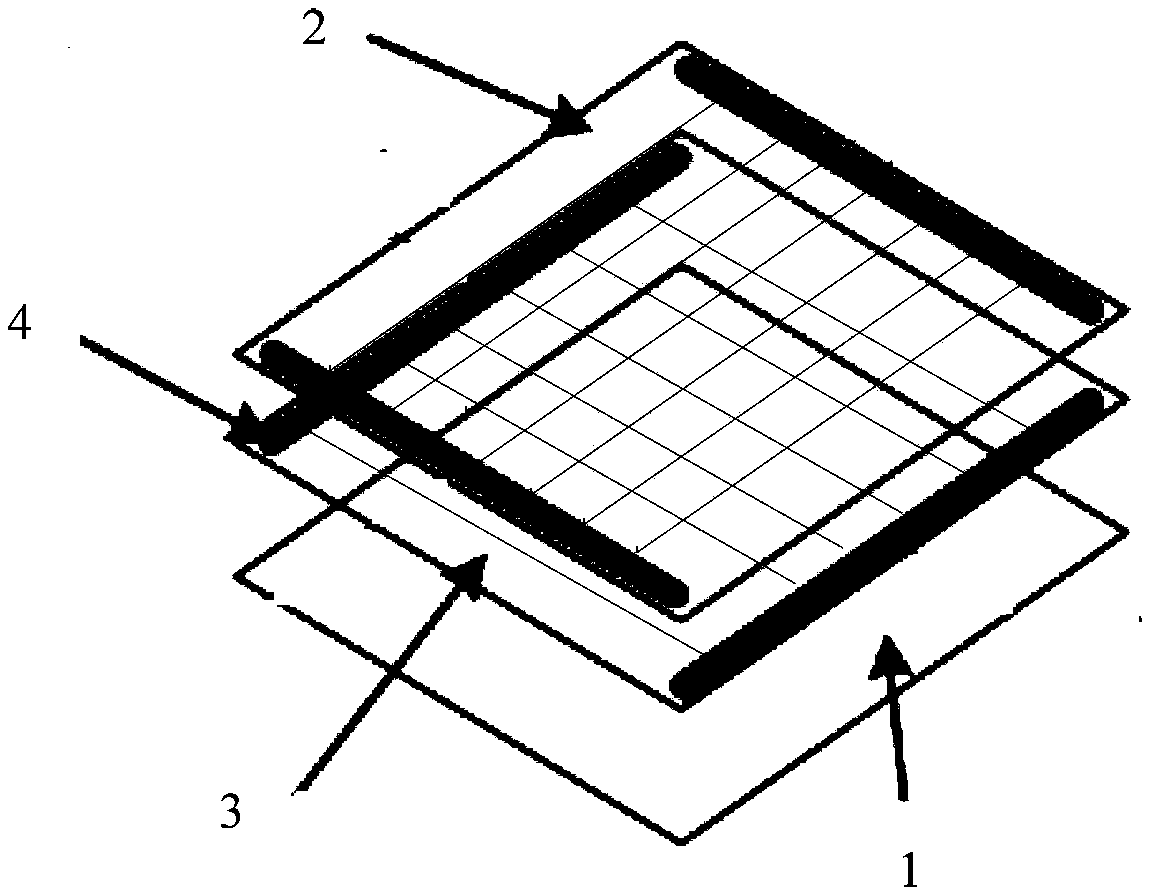

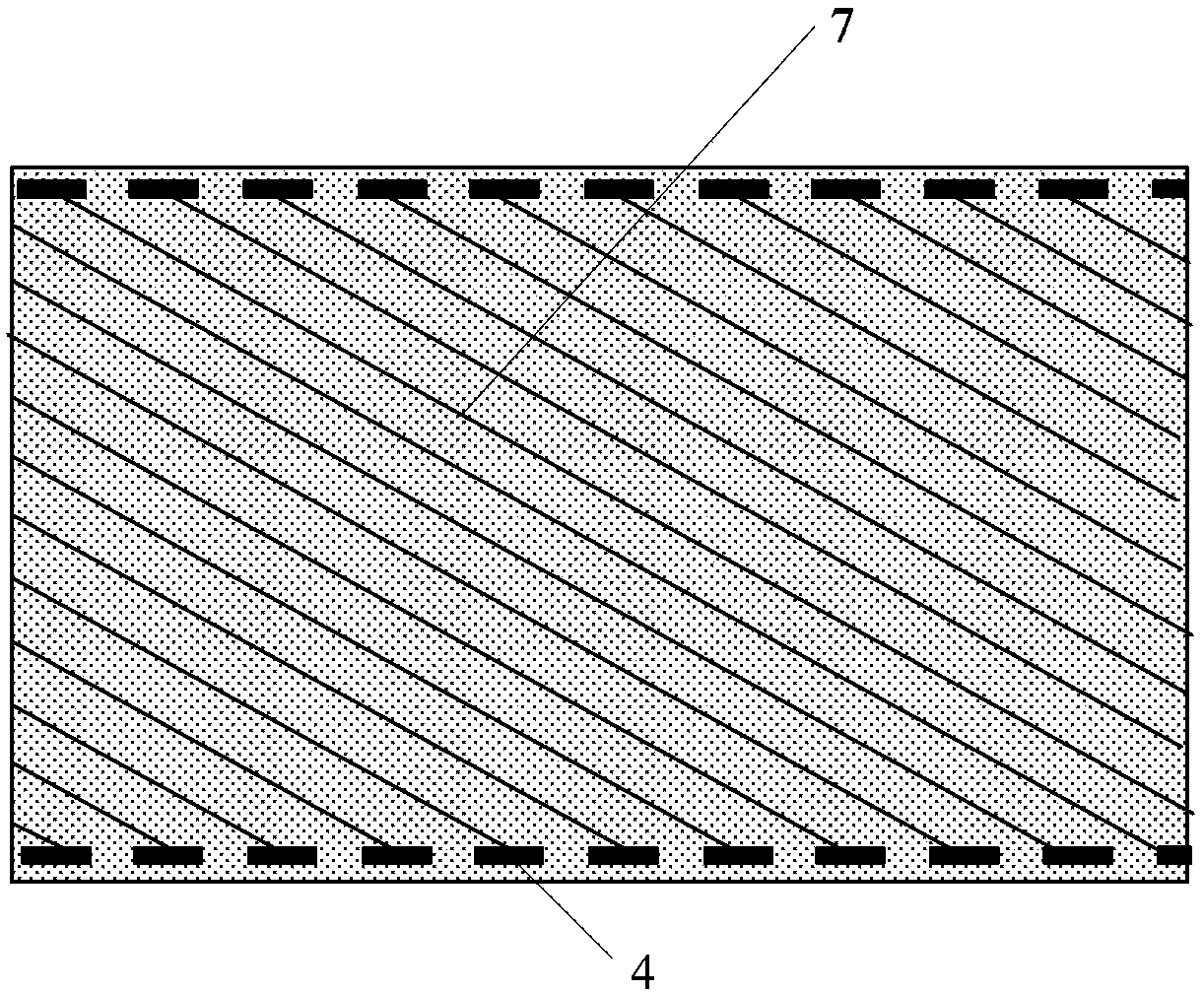

[0032] The basic idea of the present invention is to realize contact positioning through two conductive strips arranged on a single-layer transparent substrate and a strip-shaped sensing electrode arranged obliquely between the two conductive strips, and to set a grounding electrode on the upper layer of the single-layer transparent substrate. transparent conductive layer; wherein, the two conductive strips are composed of a plurality of disconnected small conductive strips.

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

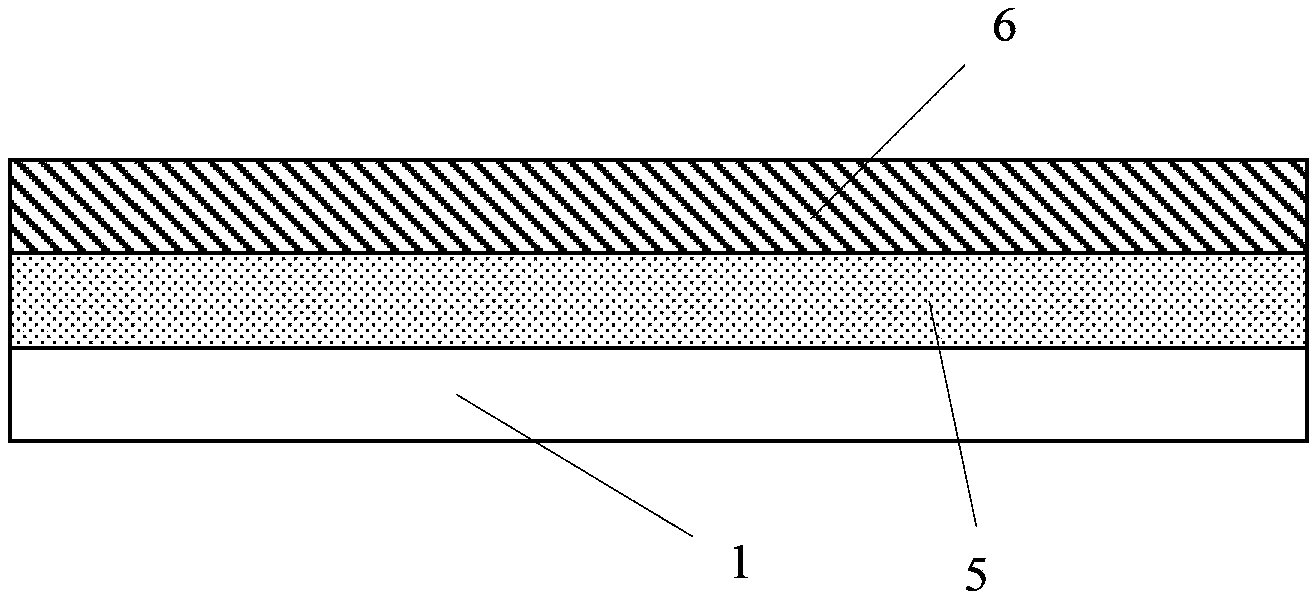

[0034] figure 2 It is a sectional view of the resistive touch screen of the present invention, as figure 2 As shown, it includes: a first substrate 1 , a second substrate 5 and a grounded transparent conductive layer 6 . Wherein, the second substrate 5 is the single-layer transparent substrate described above, and the second substrate 5 can be made of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com