an electric heating tube

A technology of electric heating tubes and tube sleeves, applied in the field of electric heating tubes, can solve the problems of difficult replacement of electric heating tubes, high processing costs, and difficult processing, and achieve the effects of avoiding electrical performance degradation, reducing processing costs, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

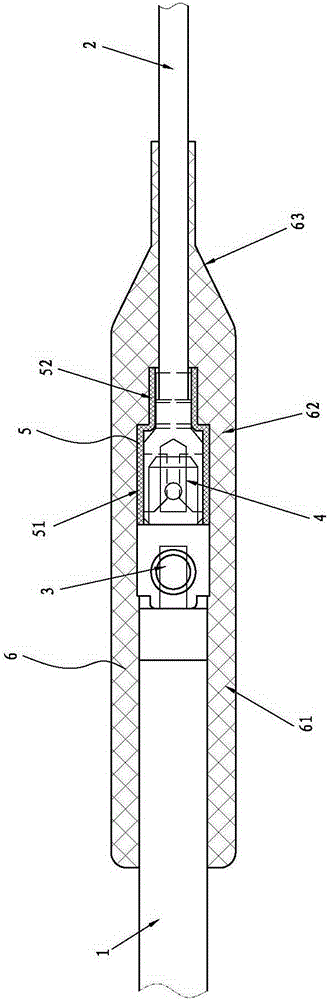

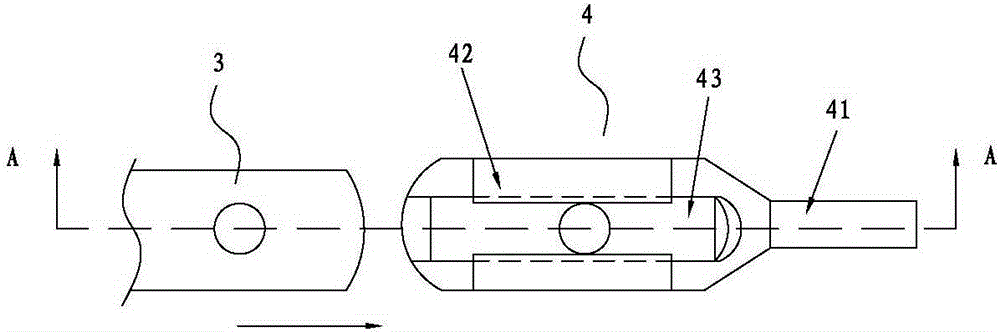

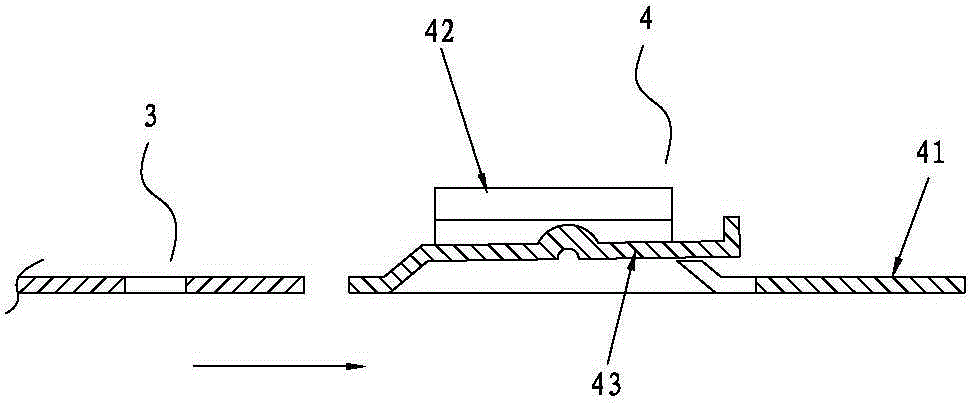

[0025] Such as figure 1 As shown, an electric heating tube includes an electric heating tube body 1 and a power cord 2, and also includes a sub-plug 3, a female socket 4, an inner silicone sleeve 5 and an outer silicone sleeve 6,

[0026] The sub-plug connector 3 is fixed on the power input pole of the electric heating tube body 1, and the power cord 2 is connected to the female socket 4;

[0027] The inner silicone sleeve 5 includes a seat cover part 51 with an open end and a wire cover part 52 with two open ends. The end cover of the seat cover part 51 has a power line hole, and the wire cover part 52 is connected with the end cover. Part 52 communicates with the power cord hole;

[0028] The outer silicone sleeve 6 includes a sleeve portion 61, a middle portion 62 wrapping the inner silicone sleeve and an outer wire sleeve portion 63 wrapping a power cord adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com