A flexible printed circuit board produced by large-scale butt jointing

A printed circuit board, large-size technology, applied in the field of printed circuit board manufacturing, can solve the problems of inability to apply high-speed transmission signals, power division signals, large signal loss, etc., to achieve the effect of reducing signal loss and accurate alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

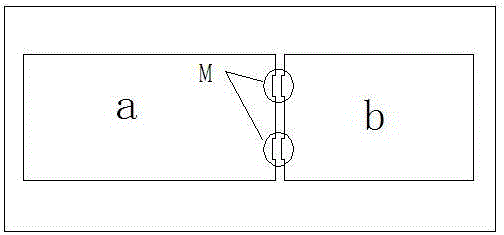

[0025] A flexible printed circuit board produced by large-scale docking, including several flexible printed circuit board units spliced together in sequence, and a protective film is provided at the joint between two flexible printed circuit board units to protect The surface of the film is bonded, welded or coated with conductive material for circuit conduction.

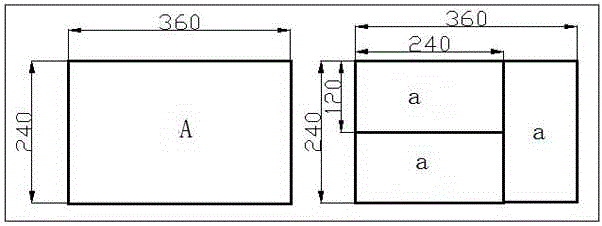

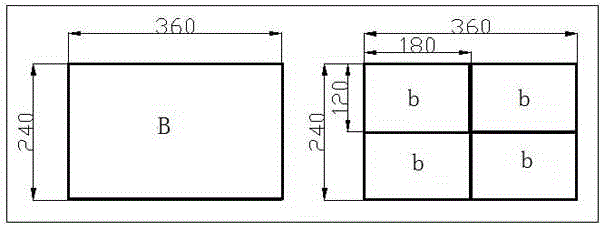

[0026] like figure 1 , 2 , according to the design plan, cut the large plate A and the large plate B into small plates a and b. like image 3 , to splice small plate a and small plate b together, the splicing side of small plate a is provided with two grooves for alignment, and the splicing side of small plate b and small plate a is provided with two protrusions matching the grooves The matching groove and the boss constitute the ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com