Limiting device used on grain screener

A technology of limiting device and screening machine, which is used in the separation of solids from solids by air flow, solids separation, chemical instruments and methods, etc. The effect of preventing displacement or falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

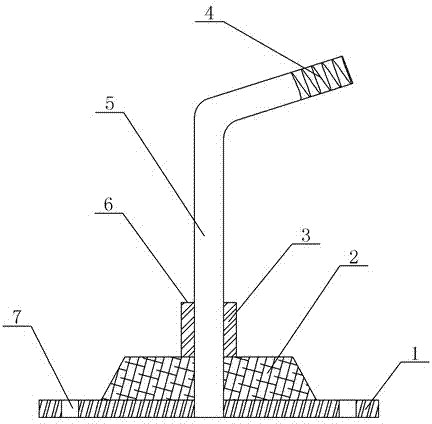

[0012] like figure 1 As shown, the present invention provides a limit device used on a grain screening machine, including a steel socket pipe 5 that can be arranged on a pipeline-type suction channel, and the steel socket pipe 5 is set to a bend angle of 125 degrees. Folded shape, one end of the steel socket pipe 5 is connected with a fastener 6 along the outer surface of the steel socket pipe, the fastener 6 includes a socket ring 3, a card seat 2 fixedly connected with the socket ring 3 and a card seat The bottom plate 1 below 2 is symmetrically provided with connecting holes 7 on the bottom plate 1, and a connecting thread 4 is provided on the outer surface of the other end of the steel socket pipe 5, and the card seat 2 is fixedly connected with the bottom plate 1. In the specific implementation, considering the steel The socket pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com