Eliminating and transferring device for voltage-withstanding test of electric heating tube shrinking machine and test method

A technology of withstand voltage test and transfer device, applied in the direction of using stable tension/pressure test material strength, electrical program control, program control in sequence/logic controller, etc. Equipment, high energy consumption and other problems, to achieve the effect of omitting manual reset, reliable working process and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

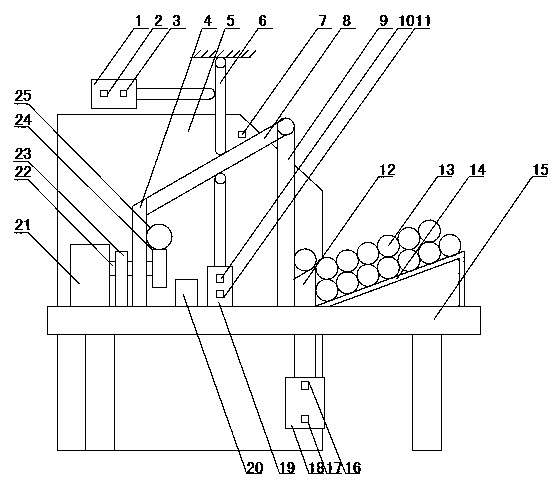

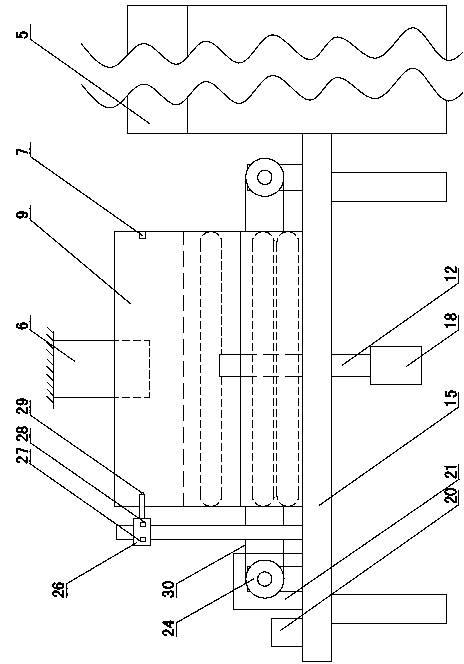

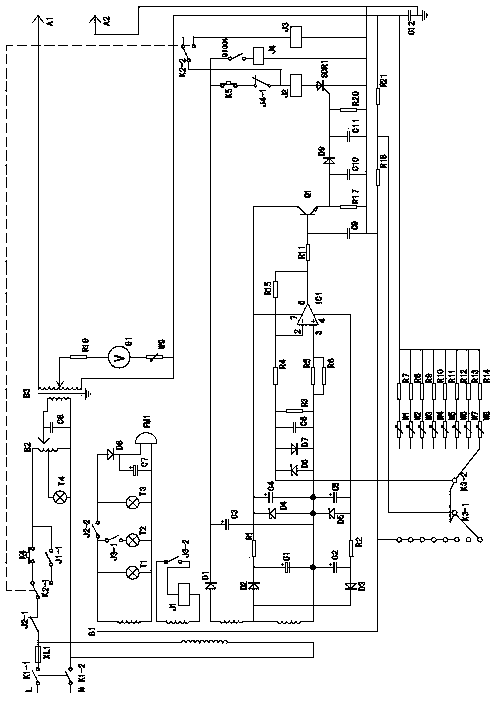

[0047] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention is described further:

[0048] Such as Figure 1~2As shown, the pressure test removal transfer device and test method of the electric heating tube shrinking machine of the present invention include five parts: an electric heating tube storage mechanism, a single tube separation mechanism, a pressure testing mechanism, a rejection transmission mechanism and a shrinking mechanism, wherein the electric heating tube The storage mechanism is set at the front end of the workbench 15, the single-tube separation mechanism is located under the workbench 15, passes through the workbench 15 from bottom to top, and is located behind the electric heating tube storage mechanism, and the rejecting transmission mechanism is set at the single-tube separation mechanism In the rear, the pressure test mechanism is fixed on the left side of the rejecting tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com