Ram enclasping mechanism

A ram, longitudinal sliding technology, applied in metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve problems such as poor flexibility and workpiece machining effects, and achieve timely and reliable positioning, good flexibility, and overall structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

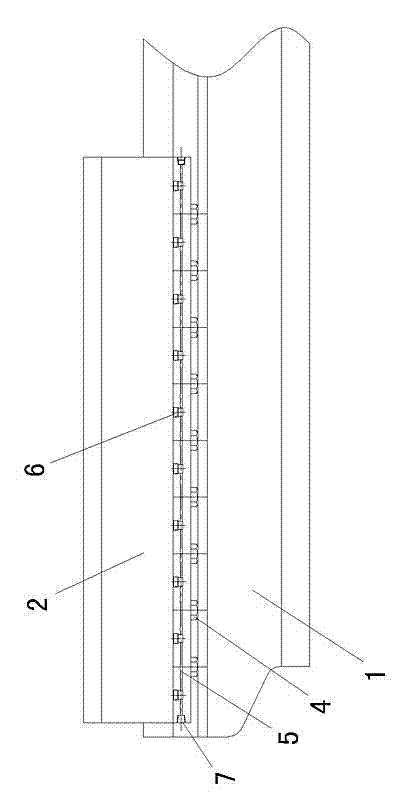

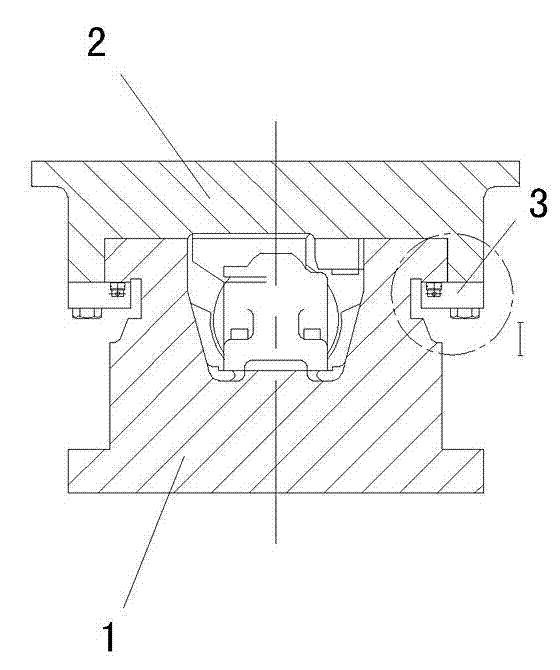

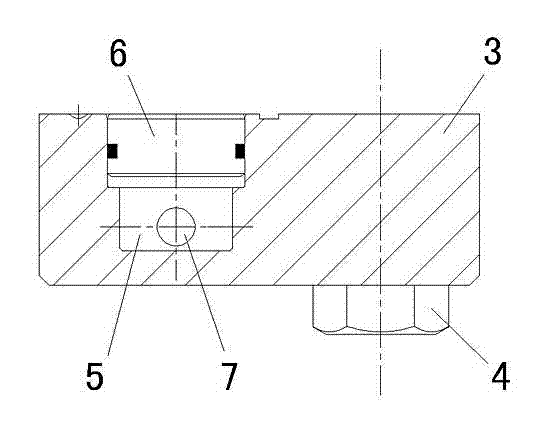

[0009] like figure 1 , 2 , 3: 1 is the guide rail of the machine tool, the guide rail 1 is equipped with a ram 2 that slides along the longitudinal direction of the guide rail, and a pressure plate 3 is fixed under the two sides of the ram 2 by bolts 4, and the pressure plate 3 is clamped on both sides of the guide rail. below. The pressure plate 3 is longitudinally provided with a hydraulic oil channel 5 that communicates with the hydraulic control mechanism. One end of the hydraulic oil channel 5 is an oil inlet 7, and the other end is blocked by a wire plug. A plurality of plungers 6 are arranged in a straight line inside the pressure plate 3 , the bottom surface of the plunger 6 is connected to the hydraulic oil channel 5 , and a sealing ring is arranged between the periphery of the plunger 6 and the pressure plate 3 .

[0010] The hydraulic oil channel 5 is connected to the hydraulic control device through pipelines and valves. When the ram 2 runs in place, each plunger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com