Closed hydrostatic guideway with hydrostatic oil film gap compensation function

A technology of oil film gap and static pressure guide rail, which is applied to the parts of grinding machine tools, grinding drive devices, metal processing equipment, etc., and can solve the problem of smaller horizontal gap of static pressure oil film, stuck guide rail, thermal deformation of static pressure guide rail, etc. Problems, to achieve the effect of improving safety and service life, increasing automatic adjustment ability, and compensating for gap changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

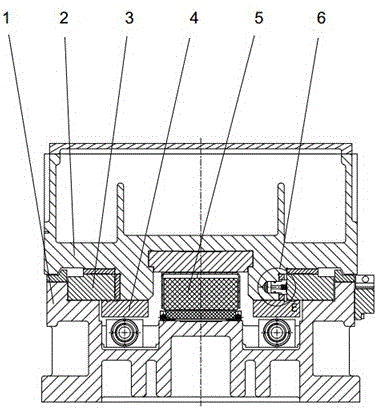

[0015] Such as figure 1 As shown, the closed static pressure guide rail with hydrostatic oil film gap compensation function of the present invention includes a base 1 , a carriage 2 , a guide rail plate 3 , a guide rail pressure plate 4 , a linear motor 5 , and a piston device 6 .

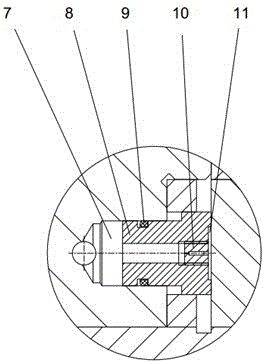

[0016] The guide rail plate 3 is installed on the base 1 , and the guide rail pressing plate 4 is installed on the carriage 2 . The guide rail plate 3, the guide rail pressing plate 4, the drag plate 2, and the base 1 form a closed static pressure guide rail. One side of the carriage 2 is equipped with several oil film contact surfaces formed by static pressure oil chambers, and several piston devices 6 are installed on the other side of the movable guide rail. The static pressure oil chamber 11 on the piston 8 and the other side of the guide rail The fixed oil cavity form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com