Treatment method for improving transmittance of solar super-white rolled glass

A treatment method, solar technology, applied in the field of glass, can solve the problem of low transmittance of solar ultra-clear rolled glass, and achieve the effect of increasing transmittance and improving conversion power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

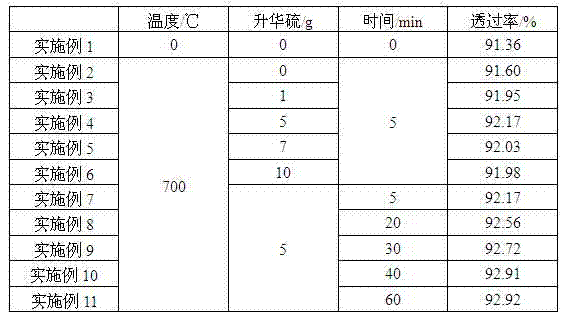

[0017] Example 1 gives the transmittance of the original glass without any treatment.

[0018] In Example 2 to Example 6, at a temperature of 700°C, the sulfur fumigation time was kept constant for 5 minutes, and the transmittance of solar ultra-clear rolled glass was compared by changing the added sublimated sulfur content.

[0019] In Example 7 to Example 11, at a temperature of 700°C, the added sublimated sulfur content was kept at 5g, and the transmittance of the solar ultra-clear rolled glass was compared by changing the sulfur fumigation time.

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com