Cement concrete regenerative coarse aggregate high -quality treatment method

A technology for regenerated coarse aggregate and high-quality treatment, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., and can solve problems such as low bulk density affecting aggregate gradation design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

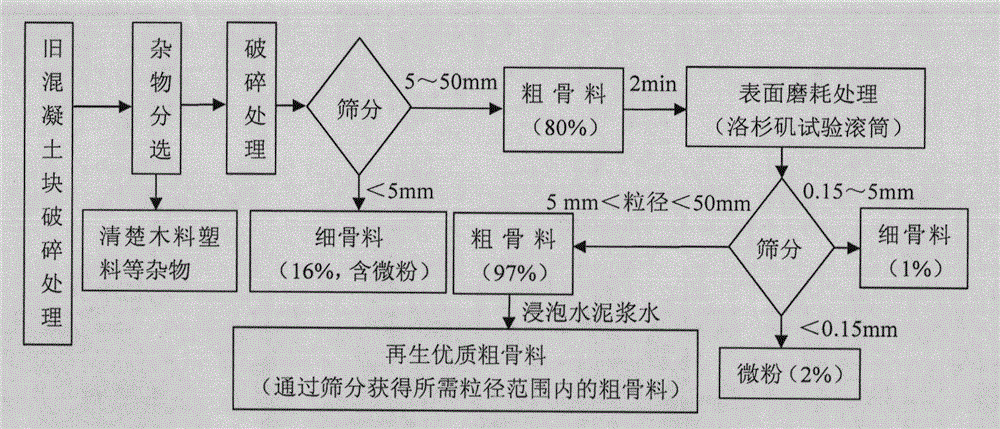

[0010] The specific method steps are as follows:

[0011] (1) Recycled coarse aggregate treatment: 500kg of old cement concrete blocks with a mass of 500kg are crushed and sieved to obtain the required 330kg of recycled coarse aggregate (particle size: 10mm~30mm) and 12kg of recycled fine powder (particle size<0.15 mm) as raw material for standby; the quality of recycled micropowder replaces 30% mixed powder of P·II42.5 Portland cement (total mass: 20kg) slurry aqueous solution, and the water-cement ratio is 1:1; the selected recycled coarse aggregate is soaked In the mixed slurry aqueous solution, the volume ratio of the regenerated coarse aggregate to the mixed slurry aqueous solution is 1:2, soak until the initial setting time of the slurry water (16h), and then use a dry cloth to absorb the surface moisture of the regenerated coarse aggregate and put it into the Oven at 105°C±5°C for 24 hours, take it out of the oven and put it in a constant temperature water tank (20°C±1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com