Composite plugging agent for coalbed methane well

A coalbed methane well and plugging agent technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of secondary leakage, lost circulation, false plugging layer is easily damaged by drilling tools, etc., to prevent leakage, The effect of improving the pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

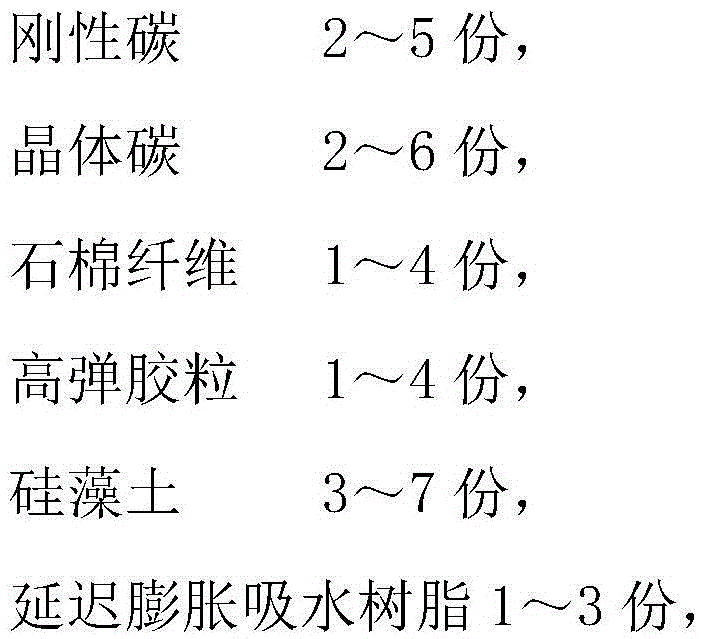

[0031] In parts by weight, take 2 parts of rigid carbon (20 mesh), 2 parts of crystalline carbon (10 mesh), 1 part of asbestos fiber, 1 part of high elastic rubber particle (10 mesh), 1 part of high elastic rubber particle (40 mesh) 1 part and 3 parts of diatomaceous earth, 1 part of delayed swelling water-absorbing resin (swelling time 10min).

Embodiment 2

[0033] In parts by weight, take 3 parts of rigid carbon (10 mesh), 3 parts of crystalline carbon (30 mesh), 2 parts of asbestos fiber, 1 part of high elastic rubber particle (10 mesh), 2 parts of high elastic rubber particle (40 mesh) 1 part and 4 parts of diatomaceous earth, 1 part of delayed swelling water-absorbing resin (swelling time 10min).

Embodiment 3

[0035] In parts by weight, take 4 parts of rigid carbon (6 mesh), 5 parts of crystalline carbon (40 mesh), 3 parts of asbestos fiber, 1 part of high elastic rubber particle (10 mesh), 3 parts of high elastic rubber particle (40 mesh) and 5 parts of diatomaceous earth, 2 parts of delayed swelling water-absorbing resin (swelling time 10min).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap