Workpiece thermal treatment method using three axial grooves and high-temperature-resistant ceramic material

A technology of high-temperature resistant ceramics and heat treatment methods, applied in heat treatment equipment, manufacturing tools, quenching devices, etc., can solve the problems of low work efficiency, large labor cost, consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

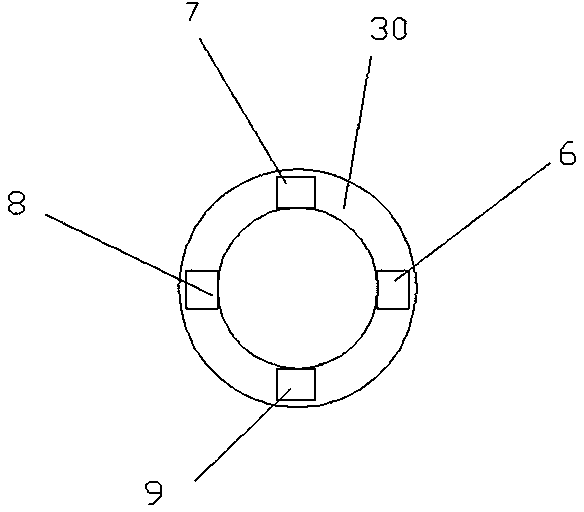

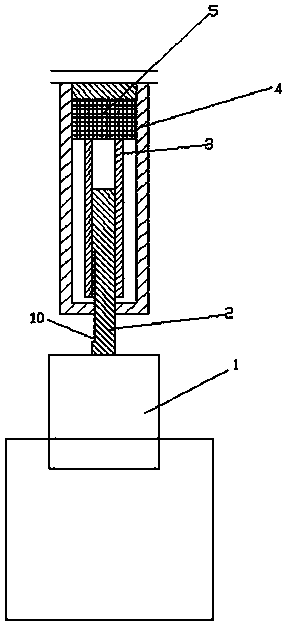

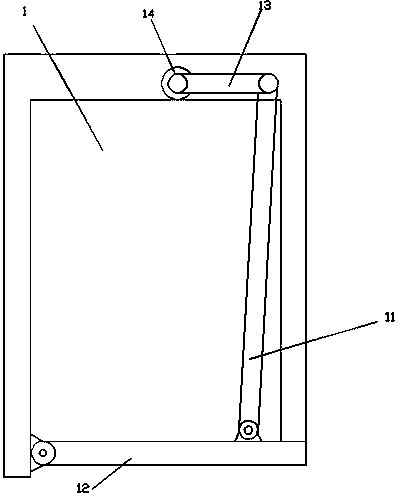

[0019] A workpiece heat treatment method utilizing three axial grooves and high-temperature-resistant ceramic materials, which uses a heat treatment device that includes four container components, four lifting components, a rotary positioning device, an annular support 30, a heat treatment components and racks.

[0020] The heat treatment assembly includes a quenching heating device 6 , an oil quenching device 7 , a tempering heating device 8 and a cooling loading and unloading device 9 , and the above four devices are uniformly arranged along the circumferential direction of the annular support 30 .

[0021] The four lifting assemblies are respectively combined with the four container assemblies correspondingly, and are used to lift and lower the container assemblies respectively; the four lifting assemblies are evenly fixed on the rotary positioning device in the circumferential direction, and the rotating positioning device The positioning device can make the combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com