Integrated efficient automatic aquatic product processing device

A processing device and automatic technology, applied in the field of food processing, can solve the problems of easy damage to jellyfish, jellyfish decay, labor consumption, etc., and achieve the effects of saving workers' physical strength, improving the qualification rate, and having a reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

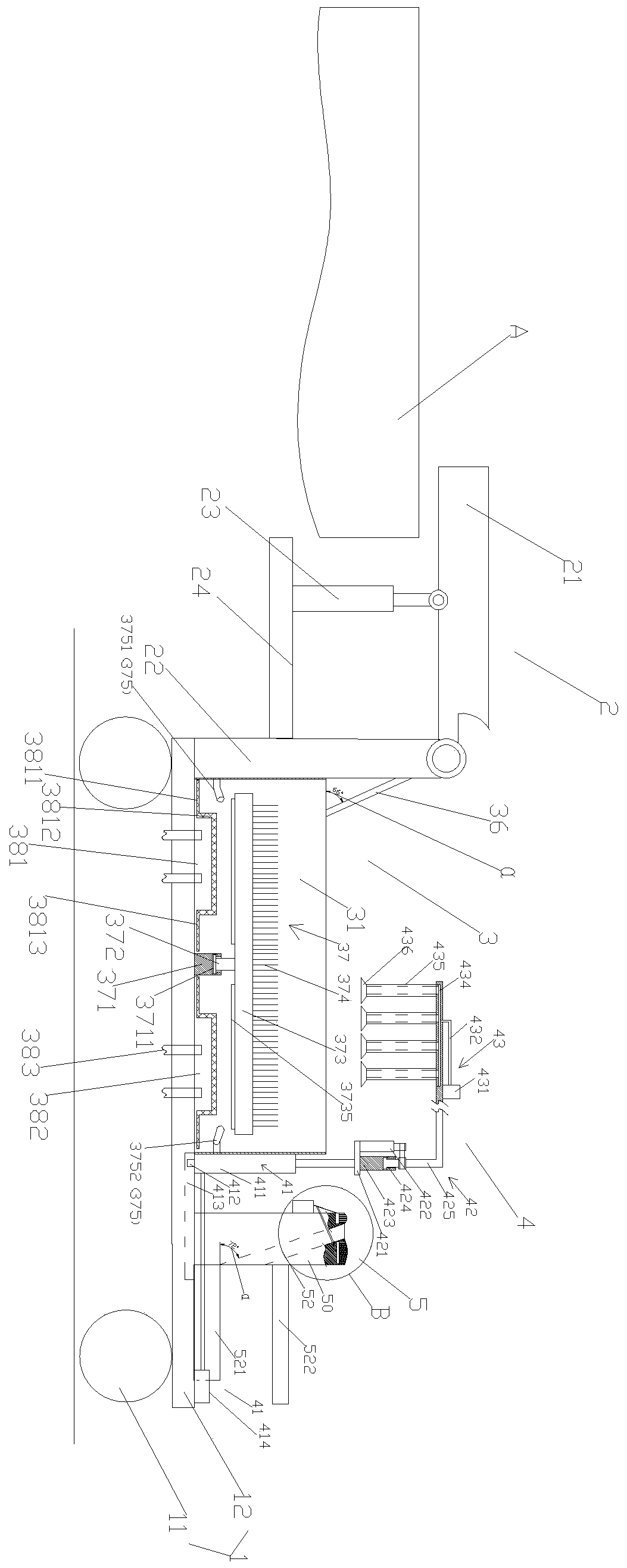

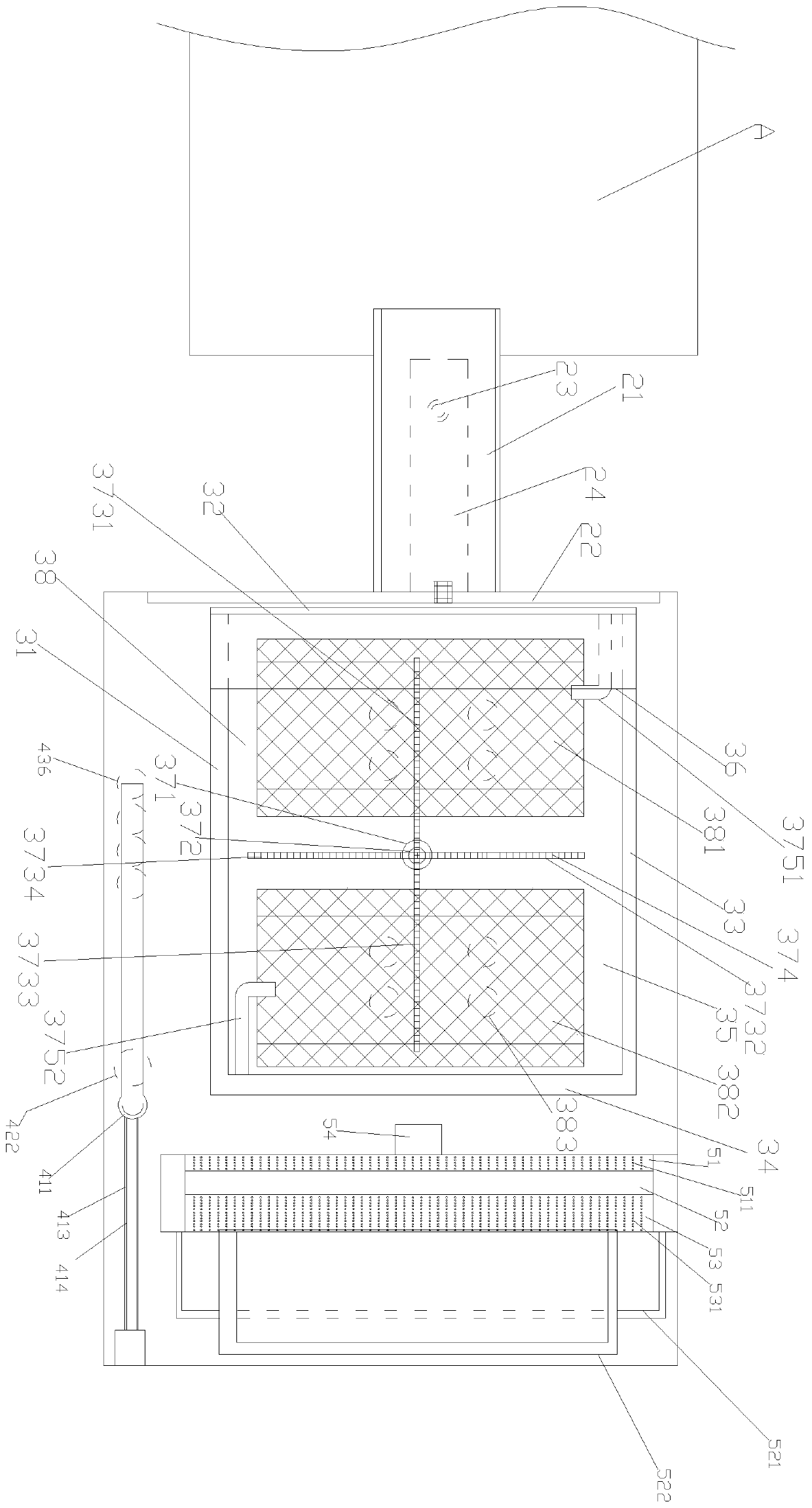

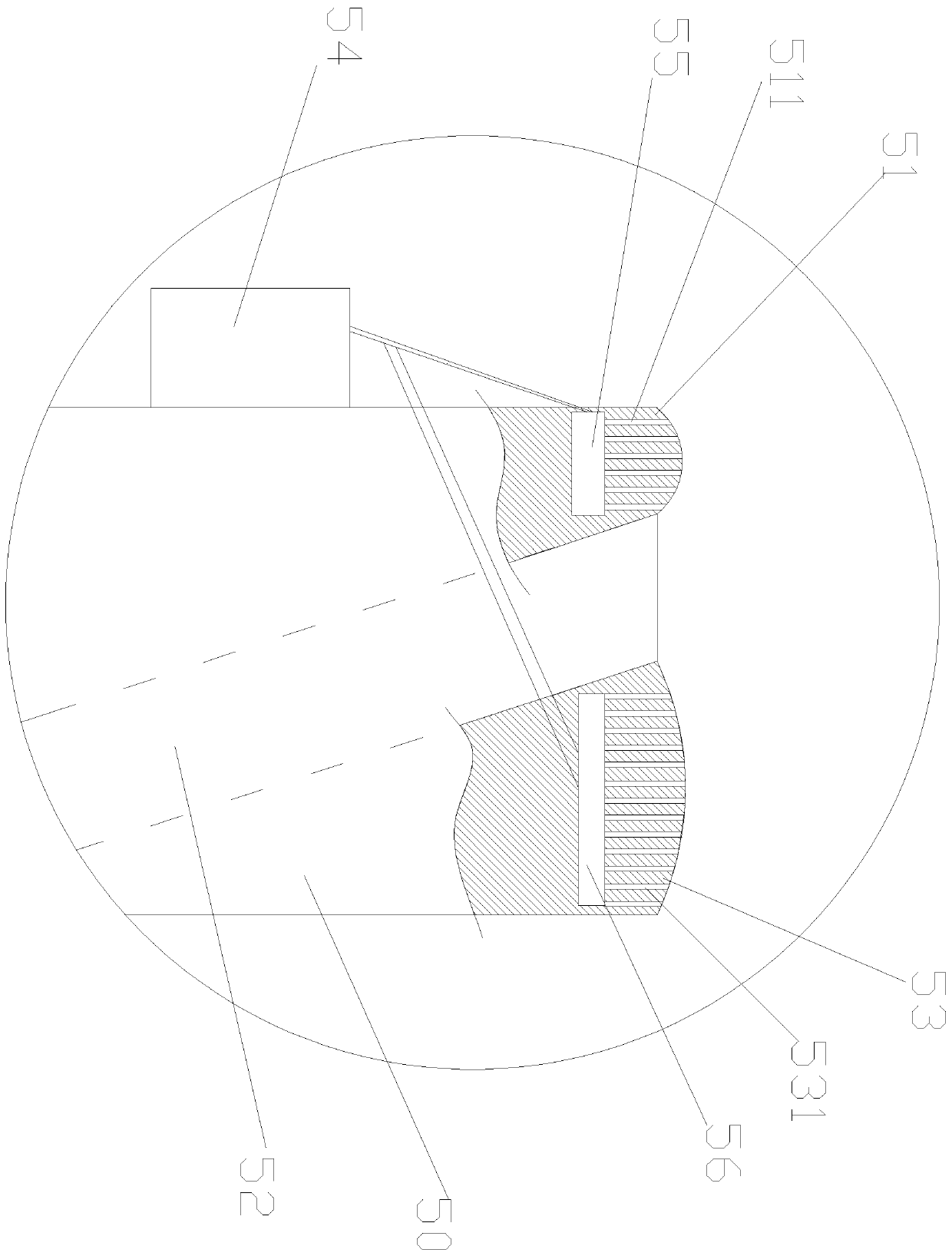

[0024] see Figure 1-3 The shown integrated aquatic product processing device includes a mobile vehicle 1, an input mechanism 2, a stirring tank mechanism 3, an adsorption mechanism 4 and a separation mechanism 5, and the mobile vehicle 1 is sequentially provided with an input mechanism 2, a stirring tank mechanism 3, and an adsorption mechanism 4 and the separation mechanism 5, the input mechanism 2 is set on one side of the mobile car 1, the stirring tank mechanism 3 is set on the input mechanism 2 side, the adsorption mechanism 4 is set on the upper part of the stirring tank mechanism 3, and the separation mechanism 5 is set on the side of the adsorption mechanism 4; As the placement platform for the input mechanism 2, the stirring tank mechanism 3, the adsorption mechanism 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com