Manufacturing process of double-side embroidered sequin embroidery

A production process and technology of sequins, applied in the field of textiles, can solve the problems of complex processing, single pattern of sequins, and the inability to turn the sequins on both sides, etc., to achieve the effect of increasing beauty, flexible patterns, and fashionable clothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A production process of double-sided inlaid sequin embroidery, and its specific processing steps (taking the pattern of the love heart on the front side of the H letter as an example):

[0028] 1) Select the fabric required for processing;

[0029] 2) Select the sequins required for processing according to the needs: select A, B, C, and D four kinds of sequins, the front and back of sequin A are yellow, the front and back of sequin B are red, and the front and back of sequin C are yellow and red , the front of the bead D is red and the back is yellow;

[0030] 3) Design the pattern of the sequins: the front of the sequins is required to be inlaid with different colors, and at the same time, when the sequins are all turned over, the reverse side also shows another inlaid pattern; specific operations:

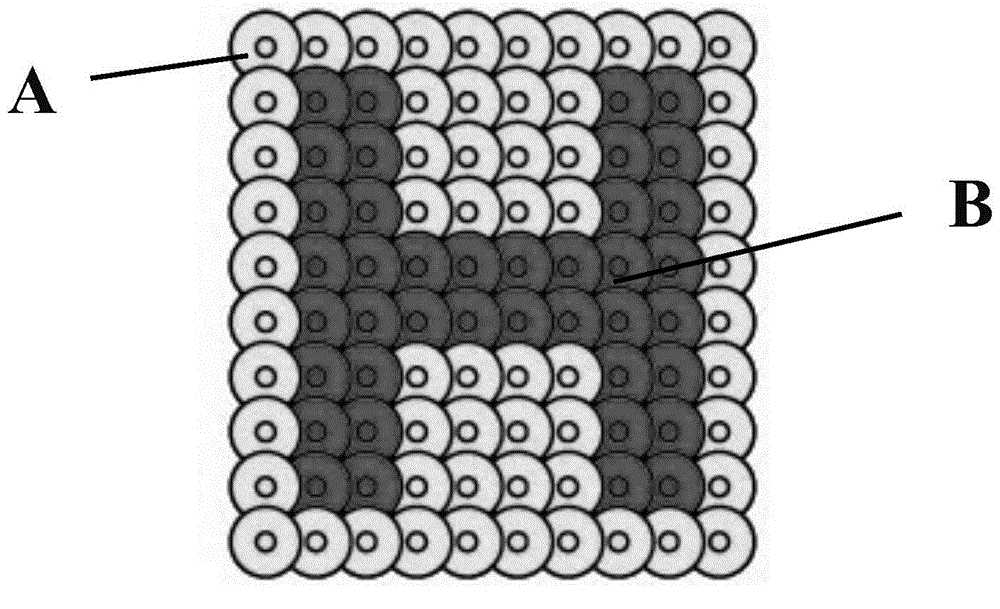

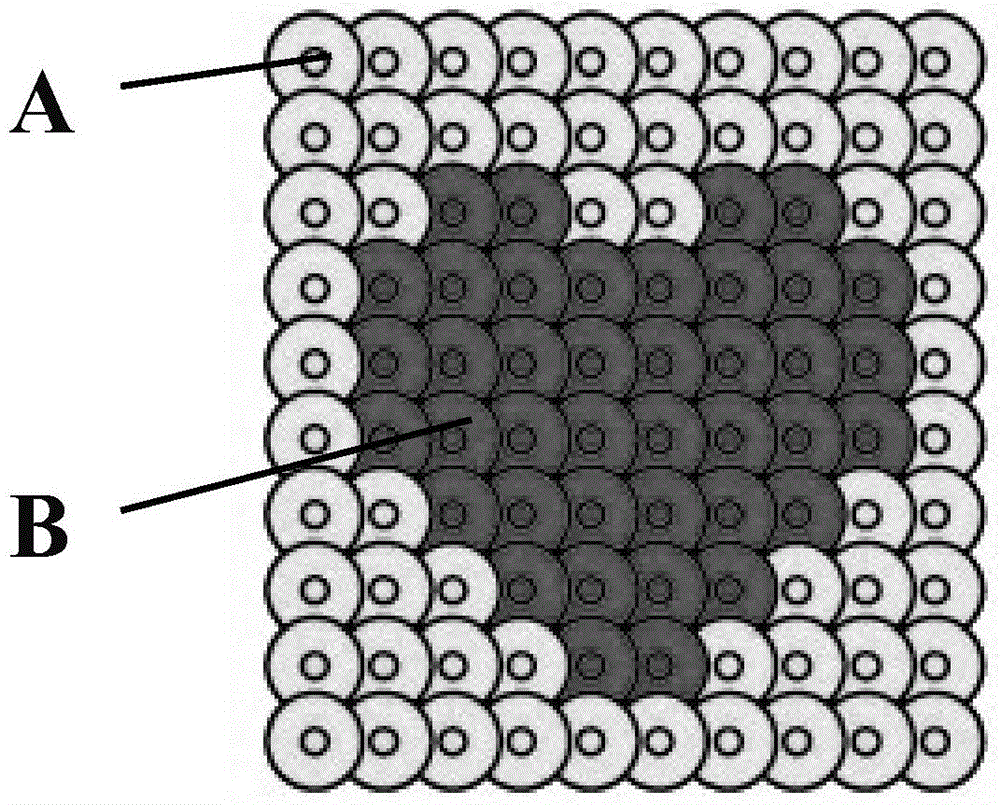

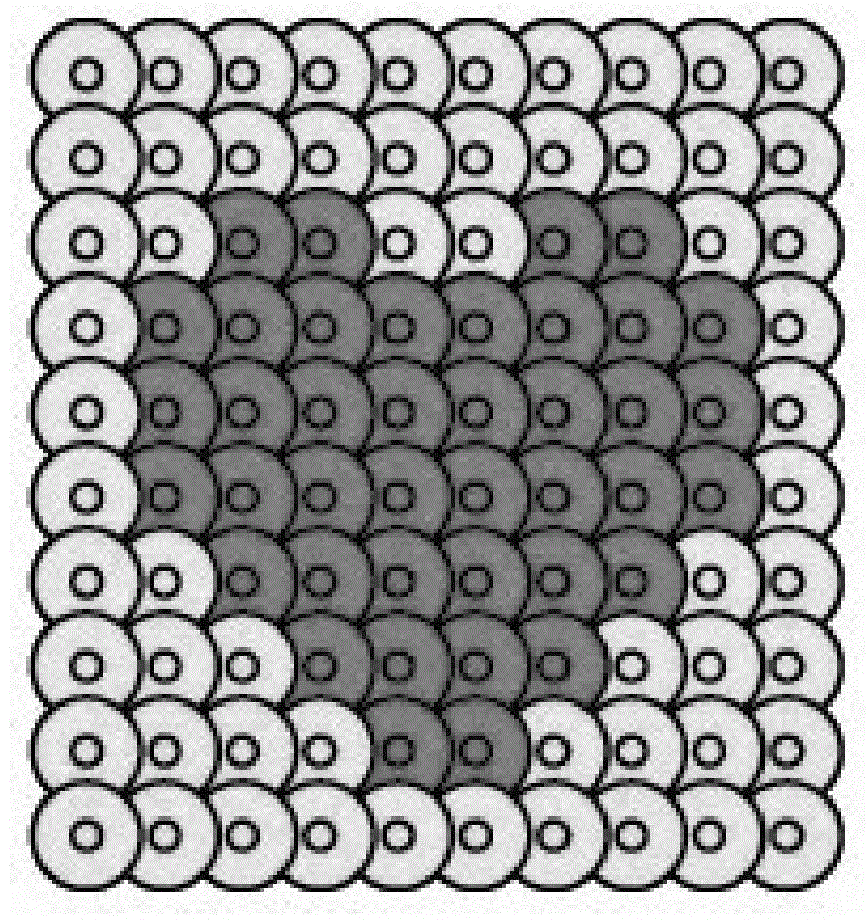

[0031] ① Use circles to simulate two patterns of sequins of the same size: one is pattern 1 on the front of the sequins, with yellow as the background color and red H inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com