Secondary hole cleaning device and method of bottom of cast-in-situ bored pile

A technology for drilling cast-in-place piles and secondary hole cleaning, which is applied to sheet pile walls, earthwork drilling, wellbore/well components, etc. Eliminate replenishment and operation time, low cost, and the effect of reducing concrete laitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and examples, but of course the following examples should not be construed as limiting the present invention.

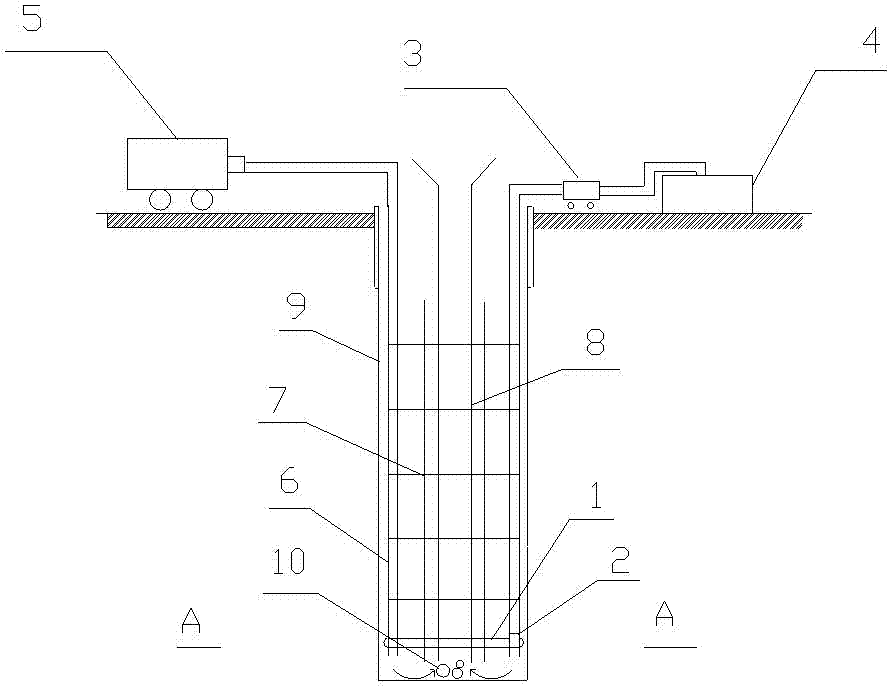

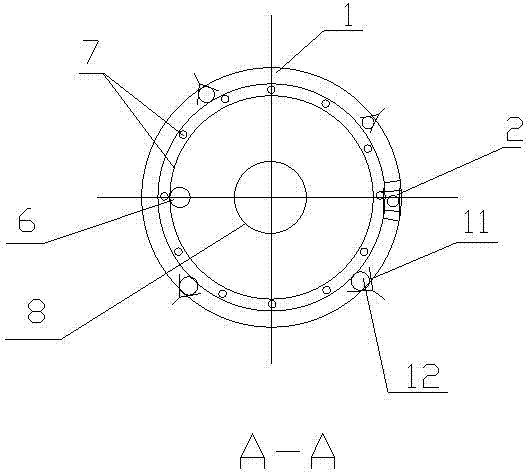

[0029] Such as figure 1 and figure 2 As shown, it is a secondary hole cleaning device at the bottom of a bored pile provided by an embodiment of the present invention, which includes an annular nozzle 1, a water guide pipe 2, a vortex pump 3, a water tank 4, an air compressor 5, and an air duct 6. The air duct 6 and the water guide pipe 2 are fixedly connected to the reinforcement cage 7 along the length direction of the reinforcement cage 7 . One end of air duct 6 links to each other with air compressor 5, and the other end of air duct 6 inserts stake hole 9 bottoms, and one end of vortex pump 3 is connected with water tank 4, and the other end of vortex pump 3 is connected with an end of aqueduct 2. The other end of the water guide pipe 2 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com