Universal coupling ground shaft for strand rope machine

A technology of universal coupling and stranding machine, applied in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of low operation efficiency, difficult installation, large moment of inertia of the ground shaft, etc., and save installation costs. , The effect of stable structure and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

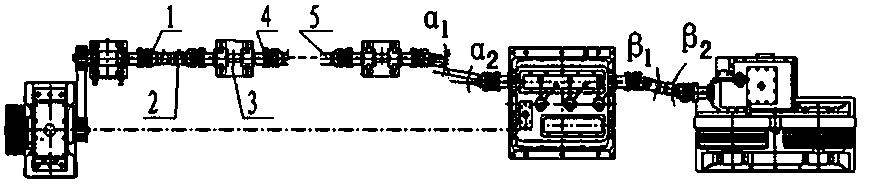

[0015] The following is a further detailed description of the shaft of the universal coupling used in the rope machine of the present invention with reference to the accompanying drawings:

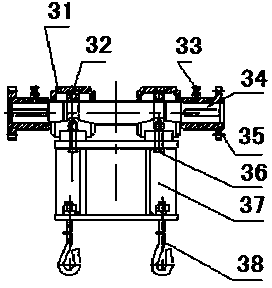

[0016] figure 1 Among them, the shaft of the universal coupling of the rope machine of the present invention is mainly composed of a single cross-shaft universal coupling 1, a telescopic intermediate shaft 2, a connecting support base 3, a connecting bolt 4 and a non-telescopic intermediate shaft 5; The ground shafts with the single cross universal joint 1 and the telescopic intermediate shaft 2 welded at both ends are respectively arranged near the toothed belt drive, the end of the fuselage shaft connecting support seat 3 and the pitch box and the pitch box Between the traction box and the traction box, the ground shafts with the single cross shaft universal coupling 1 and the non-telescopic intermediate shaft 5 are welded to the other sections of the fuselage. The connecting support 3 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com