Building formwork with repair function and construction method

A technology of building formwork and construction method, which is applied in construction, building structure, formwork/formwork components, etc., can solve the problems of inability to use for roof construction, waste of formwork resources, and low utilization rate of formwork, so as to shorten the construction time, The effect of improving utilization and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

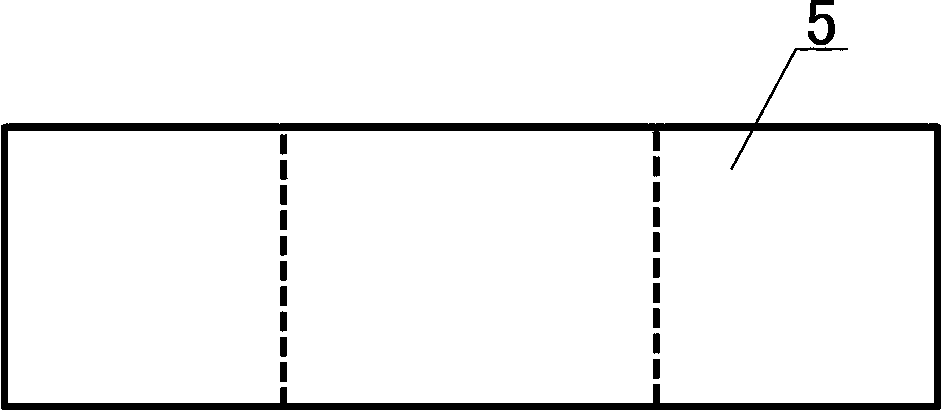

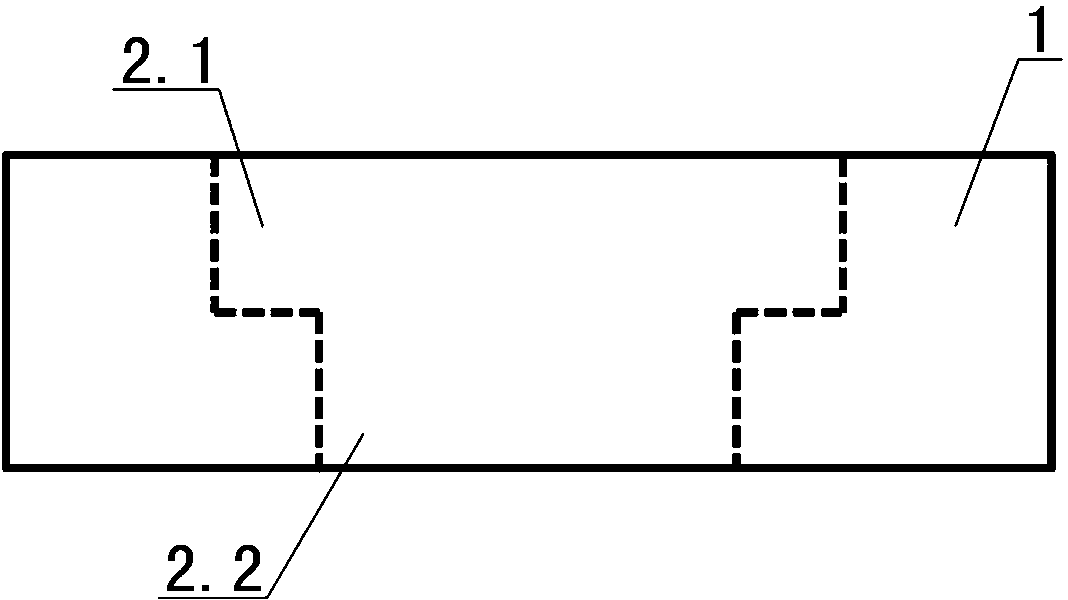

[0045] Convert formwork plate body 1 to top formwork: use plugging nails 3 to block formwork plate body 1. see Figure 3-4 As shown, the cross-sectional shape of the longitudinal axis of the through hole 2 is T-shaped, including the upper wide opening a2.1 and the lower narrow opening a2.2 that communicate with each other, see Figure 7-8 As shown, the cross-sectional shape of the longitudinal axis of the plugging nail 3 is also T-shaped, see Figure 15 As shown, the gap between the plugging nail 3 and the formwork body 1 is connected with an adhesive, and the surface of the repaired plug is kept on the same plane as the surface of the formwork body 1, so that it becomes a new top formwork and put into construction. .

Embodiment 2

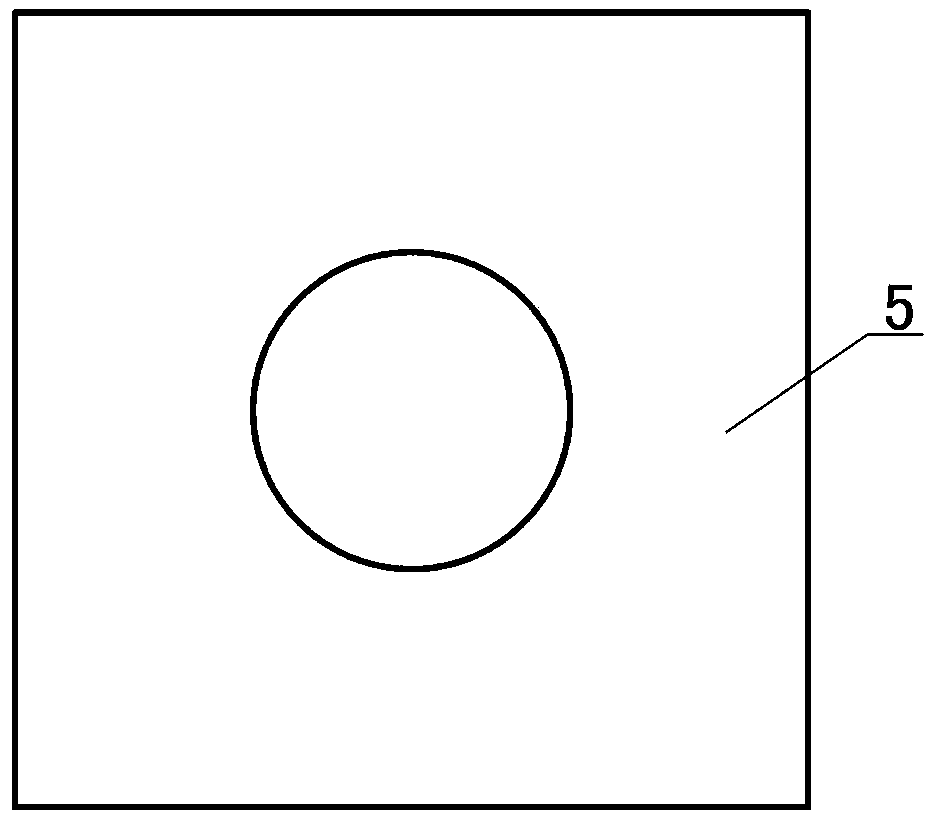

[0047] Convert the sealed top formwork in Example 1 into a re-perforated formwork: use the repair block 4 to repair the top formwork in Example 1. see Figure 13 , Figure 16 As shown, there is a bolt hole a4.1 in the middle of the repair block 4, the outer diameter D of the repair block 4 is the same as the width d of the wide mouth a2.1, and the outer diameter E of the bolt hole a4.1 is the same as that of the narrow mouth a2.2 The width e is the same, so that the bolt hole a4.1 and the narrow opening a2.2 form a new through hole, and the gap between the repair block 4 and the template body 1 is connected with adhesive to keep the surface of the repair block and the template body 1 in the same plane, making it a new perforated formwork for construction.

Embodiment 3

[0049] Convert formwork plate body 1 to top formwork: use plugging nails 3 to block formwork plate body 1. see Figure 5-6 As shown, the cross-sectional shape of the longitudinal axis of the through hole 2 is I-shaped, including the wide opening b2. Figures 9 to 12 As shown, the cross-sectional shape of the longitudinal axis of the plugging nail 3 is also an I-shape, which is an assembly used in cooperation with the female nail 3.1 and the sub-nail 3.2, and the female nail 3.1 and the sub-nail 3.2 are connected by mortise and tenon. In this example, see Figure 9-10 As shown, the female nail 3.1 is provided with a mortise 3.11; see Figure 11-12 As shown, the sub-nail 3.2 is provided with a tenon 3.21.

[0050] see Figure 17 As shown, the female nail 3.1 and the child nail 3.2 are separately arranged on both sides of the template body 1, and are fastened in the through hole through a mortise and tenon connection. For a tight connection, see Figure 11-12 , Figure 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com