Oil hydraulic pump of combination booster

A booster and combined technology, applied in the field of hydraulic pumps, can solve problems such as inaccuracy, unsatisfactory oil and air volume, and difficulty, achieving good structural manufacturability, eliminating hidden dangers of oil leakage, and environmental adaptability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will further describe the present invention in conjunction with the accompanying drawings of the embodiment, which will help the public to understand the technical content and effect of the case, but the description of the embodiment does not constitute a limitation to the technical solution. Any transformation that is merely equivalent in form should be regarded as the scope of the technical solution of this case.

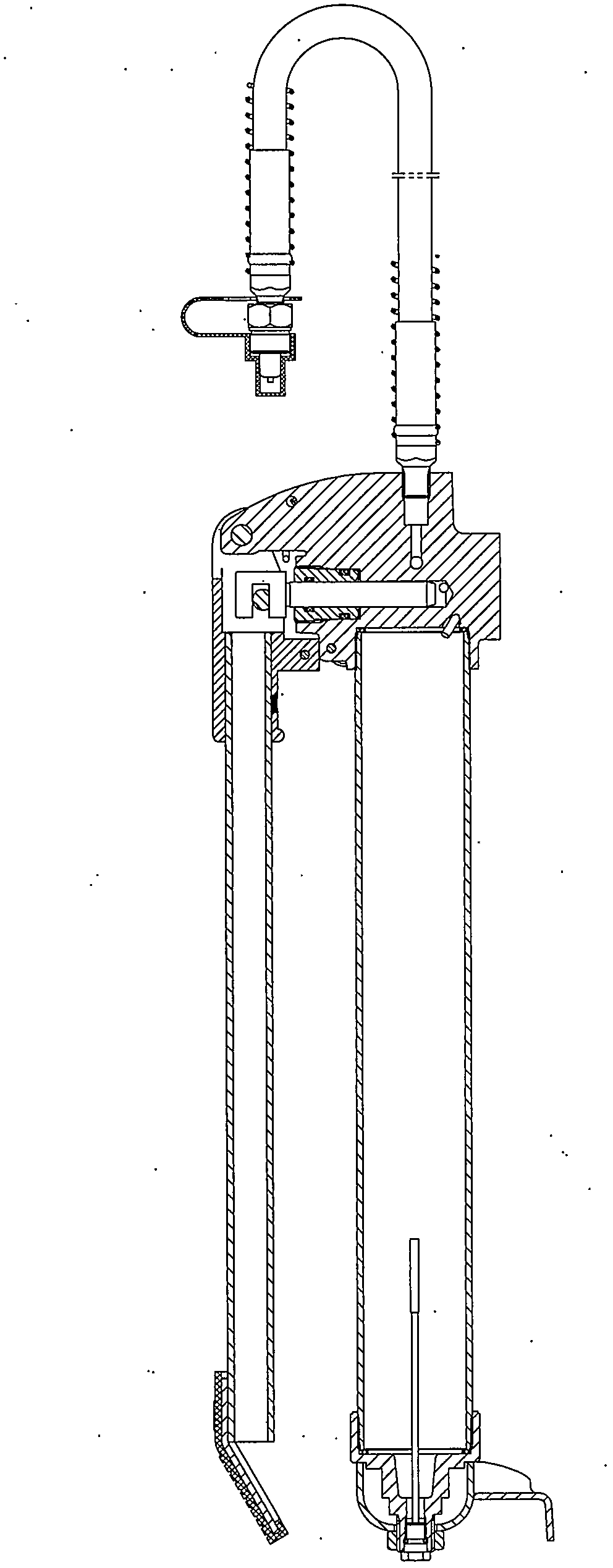

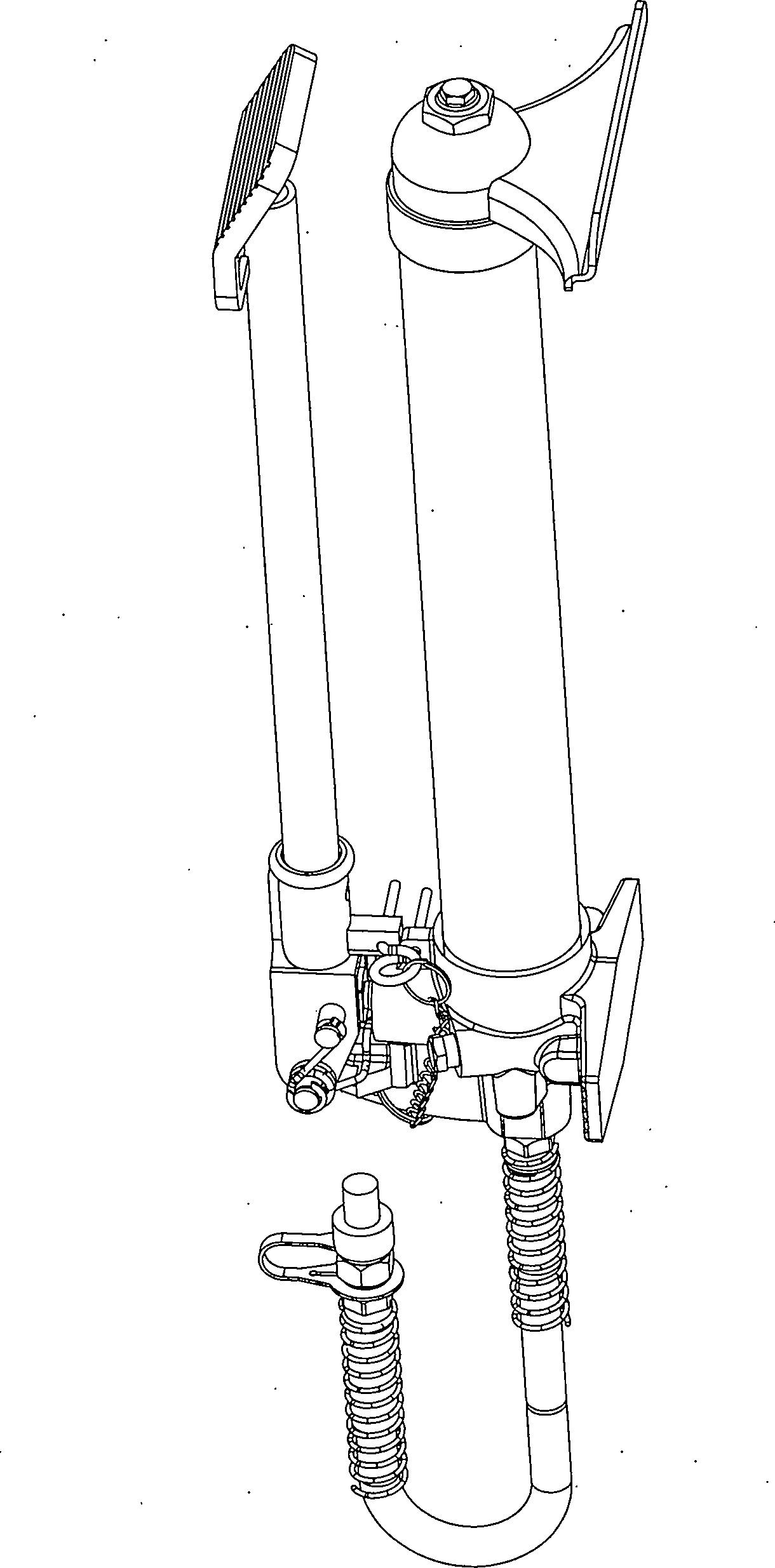

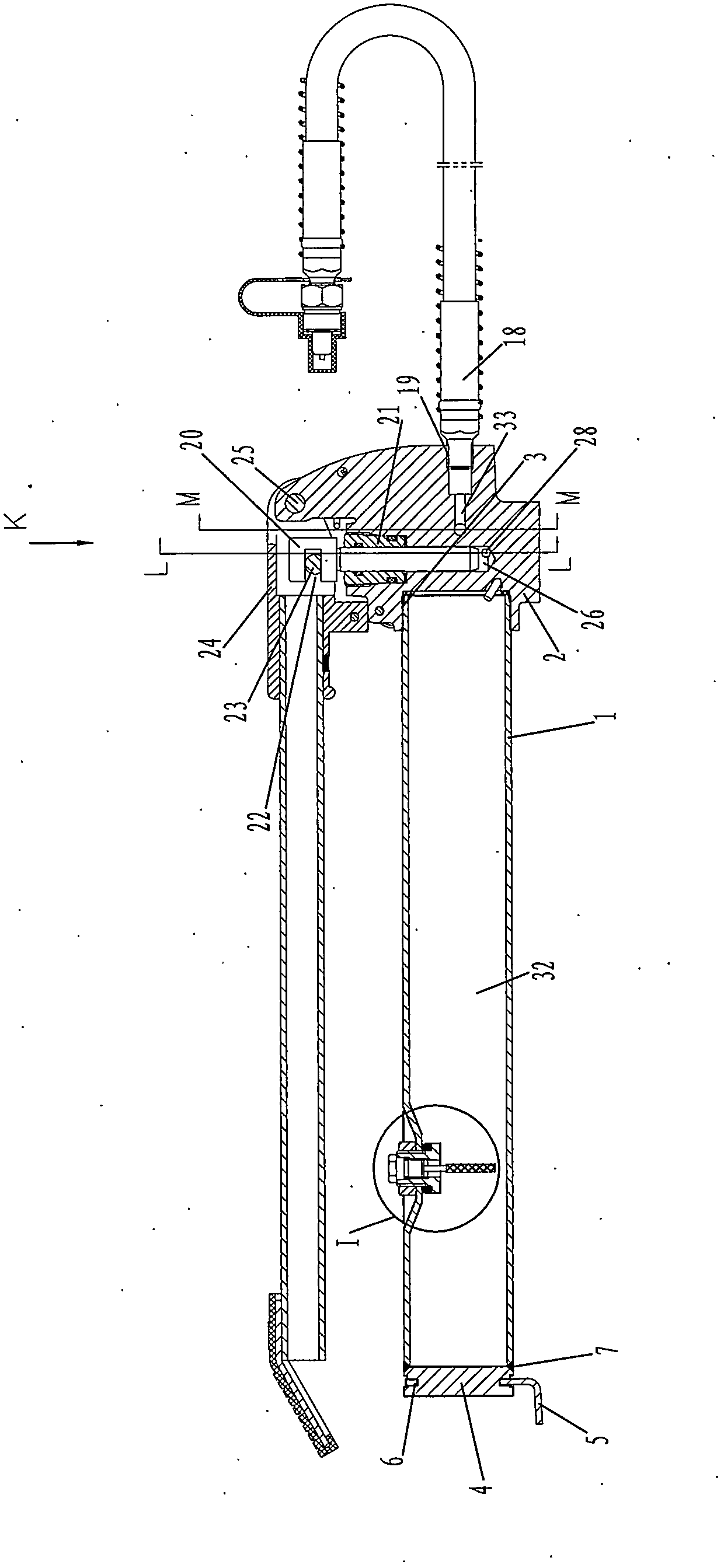

[0021] It can be seen from the accompanying drawings that the hydraulic pump of the embodiment of the present invention has six major structural features: the base 2 of the hydraulic pump includes the oil suction circuit, the oil pressure circuit, the oil suction valve 30, the oil pressure valve assembly 29, the release valve Component 37, safety valve 36; the part of the oil storage tank 1 and the base 2 are sealed and fixed with the first thread pair 3, and the welded ring-shaped entity 7 is used for sealing with the fixed connection plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com